Time for an update as a few things have occurred since my last post. All the following should obviously be read with the knowledge that I am the most picky person on the planet and zone in on things that most people would never notice, let alone pay a bloody fortune to put right...

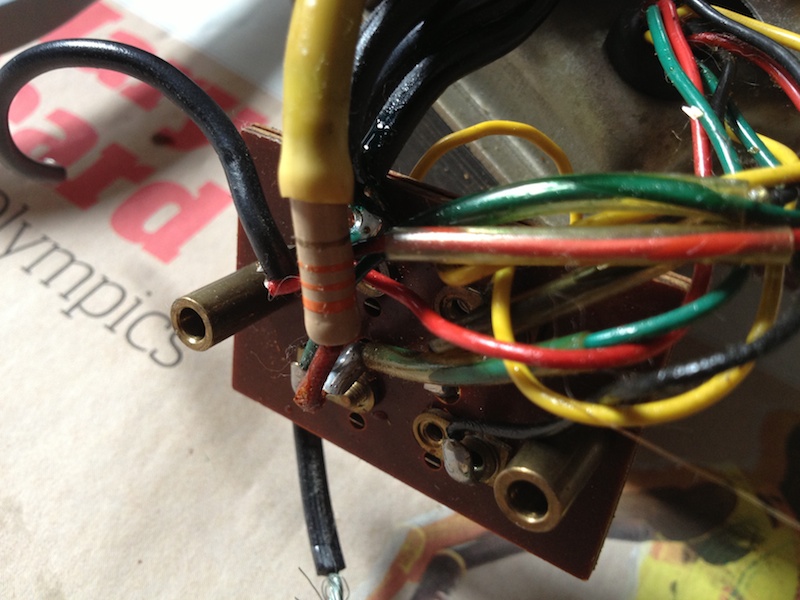

I got the deck back from Schopper, and in fairness to them it was a little quieter than when I sent it, but I still wasn't happy with it (still a lot noisier than either the 301 or Lenco L70). Annoying as their work was around £400 or so (nothing about TD-124s is ever cheap IME). They'd stuck a couple of resistors into the plinth to drop my high mains voltage down a bit, but even so the stepped pulley still did it's chattering thing and I still suspected the bearings (which annoyingly they couldn't change despite the claims on their website as apparently there are "different types"). All in all not a great experience, but the deck was quieter than it was, and if I used a lightbulb as well, very quiet indeed.

That was until late last week when I spotted what looked like a nice condition chassis on eBay (

link). I found myself clicking the Buy It Now figuring it would either fix the issue or at least give me a spare chassis to send to a machine shop to get some custom bearings made and fitted. It turned up this morning and is indeed in very nice condition, I'd say just a smidge better than the one I have already, which is very nice indeed, I'd grade it as a very tidy EX/EX, just the usual slight paint crazing around the main bearing from an oil-leak, but they all seem to have that, and you can't see it anyway. I gave it a good clean and I'm very pleased with it:

It's a little later than my existing one with (9268* vs. 8569*) and I suspect one of the very last 124s ever made.

The underside is very clean too, no visible wear to the support posts etc.

I spent the weekend reading absolutely everything on the whole internet to prepare myself for the task of completely stripping the deck down and rebuilding it into it's new home. Time well spend for sure as I'm certain I'd have broken the fragile metal control-band etc had I not understood exactly how to remove it (one removes the speed lever mech, metal belt and cam assembly as one single entity,

very carefully rather than removing the belt itself).

Anyway I've successfully done the chassis transplant. It's all back together with no hitches, breakages or bits left over at all. I took all my time very carefully cleaning every single part too, so it's as clean and shiny as it can be. I'm now leaving it running for a while, I'll give it a few hours. At the moment it is running nice and quietly (about as quiet as the other chassis did with resistors and light-bulb), though it's early days yet as all the oil may well fall out, but certainly positive so far. It's been a really good learning curve too, I now feel a lot more confident about the deck now I've had it stripped-down to component level. I'm rather chuffed with myself for not bollocksing anything up! Will report back later once it's been up and running for a good while.