Tony L

Administrator

Edit/warning: Anyone coming fresh to this thread please read it as a blog, a journey, a learning curve etc. Do not view it as a linear instruction manual. This thread contains many rabbit holes, blind alleys, cul-de-sacs, a lot of money spent unnecessarily and following some advice I now view as dubious. If anything it makes more sense read backwards going from what I ended up happy with and then looking at all the errors made getting to that point. Despite the various pitfalls it was an enjoyable journey and I really like the 124 restoration I ended up with.

Here is the start of the thread:

My TD-124/II is cosmetically in very good condition and shows no evidence of being butchered / tampered with over it's life, e.g. all the screw-heads below are sharp and clean, the chassis and platter are largely unmarked etc. It looks just as the picture above aside from it's now sporting a Stereo Lab arm board as I had one knocking around. There are however some parts that were less than perfect, and I've come to the conclusion that it probably makes sense to simply hang the expense and replace them than keep buying and selling 124s in the vain hope I might eventually get a top platter etc that meets with the approval of my OCD tendencies etc.

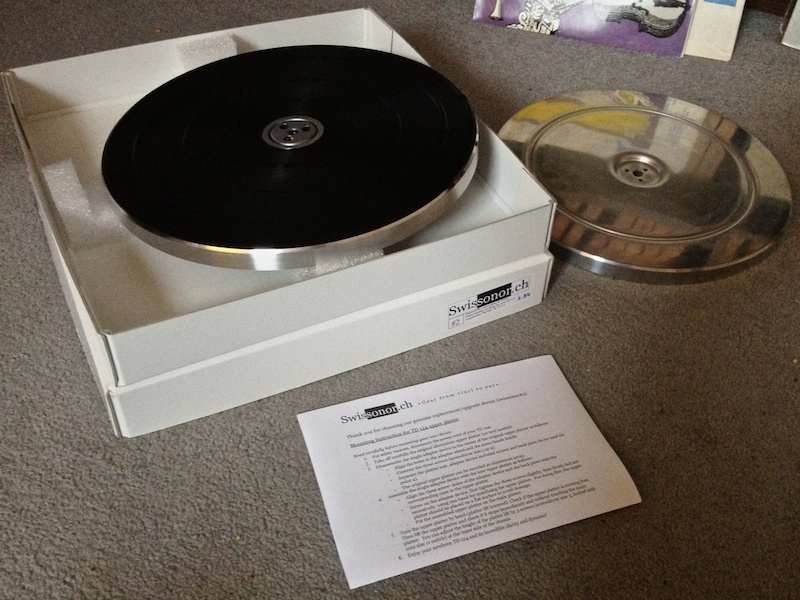

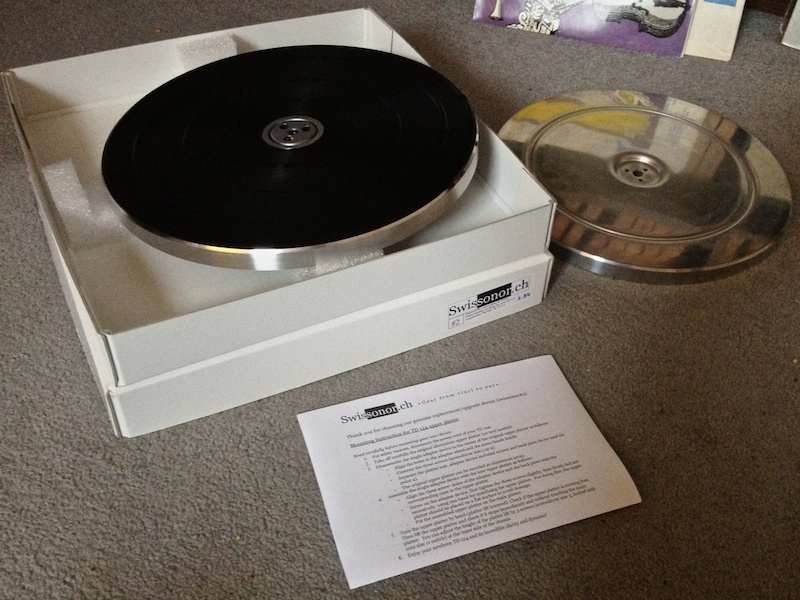

Thus the first thing to fall through the letterbox was a Swissonor upper platter:

My original upper platter (right) is a very annoying thing as it is in absolutely perfect condition; not dinged, warped or otherwise abused at all, a real minter. It is however a bit of a 'Friday afternoon job' and the machining / chamfering of the top edge is just a mess. It really should have been caught by quality control, or failing that the original purchaser should have taken it back to the shop as due to this machining error there is a dip of around 1.5mm per rotation on the top edge only, i.e. the bottom edge and front runs straight and true, yet the chamfer at the top is inconsistent at one side. It irritated the crap out of me so it had to go before I could really take this deck seriously. For a couple of years I'd been under the impression the Swissonor replacement upper platter was no longer made as it has vanished from the Shopper site. It can however still be had from Swissonor directly and is a nice piece of kit and looks indistinguishable from an original. Except it's actually flat.

I thought I'd give my 124 a full service at this point as it was a good three or so years since I'd last done it. As such I stripped it down and was met with a real shock when I cracked the bearing open. My memory of this bearing was that it was absolutely perfect. I can remember no flaws at all the first time I serviced it. But now:

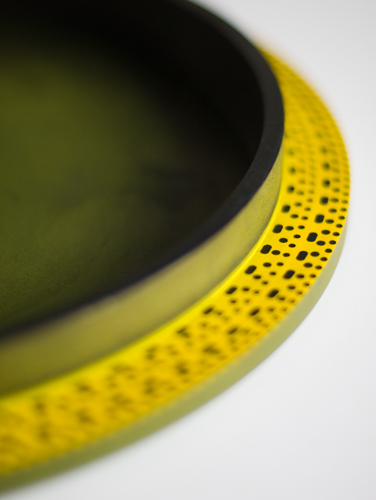

Check out that black spot / pit! There are two others too, all rough to the touch and it's definitely pitting not surface dirt. I mentioned this to Urs Frei from Swissonor along with a picture and he reckons there are some very unlikely conditions where if a piece of 'noble metal' is present in the wrong kind of oil the whole bearing assembly can act as a battery. It's a better explanation than I have, which is none at all. I do not understand this at all, though can't believe I failed to notice it when I initially serviced this bearing - I just notice stuff like this, it's what I do. Certainly not a cheap thing to put right either, basically the options were taking a risk on buying yet another TD-124 and hoping it had a perfect bearing, or spending about the same amount on a beautifully engineered replacement from Shopper. I gritted my teeth and opted for the latter:

It really is a beautiful thing, even if it does cost the same as a half decent second hand LP12 or whatever.

Luckily my E50 motor really is in great shape, the spindle shows next to no wear, and with a little careful jiggling of the motor casing, as is the way with E50s, can be coaxed to run very quietly, to the point I can't hear it with my ear a couple of inches from it (assuming the belt and intermediate wheel are not connected). I'll strip it down again tonight to clean and relube it with the Shopper oil, which is lighter than what I have in there at present, so I may get it even quieter again.

So, that's where I am at present. I've also got a Swissonor grey iron lower platter in the mail to me and I'm quietly on the hunt for a new idler wheel. The grey iron platter is regarded as a big upgrade on the light zinc alloy one my deck is fitted with, it apparently brings all the sonic advantage of the original cast iron and more, but with none of the magnetic attraction. I'm certainly hoping a drop in rumble anyway as the alloy one does sing along with the idler wheel a fair bit. I want to take this 124 as far as I possibly can within it's current aesthetic context, i.e. the beautiful mint condition period-correct 3009 Series II and DL103 are staying, but I want to get the deck itself performing as close to it's capabilities possible. It's a keeper.

PS Must mention Joachim Bung's Swiss Precision book, which also turned up recently and is a truly beautiful thing covering all things TD-124 along with it's historical backdrop of Lenco, Garrard, Thorens, Ortofon, SME, Shure etc, all of which are covered in some detail. A remarkable book and it's great to see someone documenting this classic era of audio so well.

Here is the start of the thread:

My TD-124/II is cosmetically in very good condition and shows no evidence of being butchered / tampered with over it's life, e.g. all the screw-heads below are sharp and clean, the chassis and platter are largely unmarked etc. It looks just as the picture above aside from it's now sporting a Stereo Lab arm board as I had one knocking around. There are however some parts that were less than perfect, and I've come to the conclusion that it probably makes sense to simply hang the expense and replace them than keep buying and selling 124s in the vain hope I might eventually get a top platter etc that meets with the approval of my OCD tendencies etc.

Thus the first thing to fall through the letterbox was a Swissonor upper platter:

My original upper platter (right) is a very annoying thing as it is in absolutely perfect condition; not dinged, warped or otherwise abused at all, a real minter. It is however a bit of a 'Friday afternoon job' and the machining / chamfering of the top edge is just a mess. It really should have been caught by quality control, or failing that the original purchaser should have taken it back to the shop as due to this machining error there is a dip of around 1.5mm per rotation on the top edge only, i.e. the bottom edge and front runs straight and true, yet the chamfer at the top is inconsistent at one side. It irritated the crap out of me so it had to go before I could really take this deck seriously. For a couple of years I'd been under the impression the Swissonor replacement upper platter was no longer made as it has vanished from the Shopper site. It can however still be had from Swissonor directly and is a nice piece of kit and looks indistinguishable from an original. Except it's actually flat.

I thought I'd give my 124 a full service at this point as it was a good three or so years since I'd last done it. As such I stripped it down and was met with a real shock when I cracked the bearing open. My memory of this bearing was that it was absolutely perfect. I can remember no flaws at all the first time I serviced it. But now:

Check out that black spot / pit! There are two others too, all rough to the touch and it's definitely pitting not surface dirt. I mentioned this to Urs Frei from Swissonor along with a picture and he reckons there are some very unlikely conditions where if a piece of 'noble metal' is present in the wrong kind of oil the whole bearing assembly can act as a battery. It's a better explanation than I have, which is none at all. I do not understand this at all, though can't believe I failed to notice it when I initially serviced this bearing - I just notice stuff like this, it's what I do. Certainly not a cheap thing to put right either, basically the options were taking a risk on buying yet another TD-124 and hoping it had a perfect bearing, or spending about the same amount on a beautifully engineered replacement from Shopper. I gritted my teeth and opted for the latter:

It really is a beautiful thing, even if it does cost the same as a half decent second hand LP12 or whatever.

Luckily my E50 motor really is in great shape, the spindle shows next to no wear, and with a little careful jiggling of the motor casing, as is the way with E50s, can be coaxed to run very quietly, to the point I can't hear it with my ear a couple of inches from it (assuming the belt and intermediate wheel are not connected). I'll strip it down again tonight to clean and relube it with the Shopper oil, which is lighter than what I have in there at present, so I may get it even quieter again.

So, that's where I am at present. I've also got a Swissonor grey iron lower platter in the mail to me and I'm quietly on the hunt for a new idler wheel. The grey iron platter is regarded as a big upgrade on the light zinc alloy one my deck is fitted with, it apparently brings all the sonic advantage of the original cast iron and more, but with none of the magnetic attraction. I'm certainly hoping a drop in rumble anyway as the alloy one does sing along with the idler wheel a fair bit. I want to take this 124 as far as I possibly can within it's current aesthetic context, i.e. the beautiful mint condition period-correct 3009 Series II and DL103 are staying, but I want to get the deck itself performing as close to it's capabilities possible. It's a keeper.

PS Must mention Joachim Bung's Swiss Precision book, which also turned up recently and is a truly beautiful thing covering all things TD-124 along with it's historical backdrop of Lenco, Garrard, Thorens, Ortofon, SME, Shure etc, all of which are covered in some detail. A remarkable book and it's great to see someone documenting this classic era of audio so well.