My approach has been to get the 124 to run as quietly as I possibly can without relying on a heavyweight plinth as I don’t seem to be a fan of mass-damping sonically. I accept I’ll never get it as quiet as a belt-drive deck, but I’ve certainly got it quiet enough for my taste, and I’ve done so without killing the life and soul of the deck. With experience you will grow to learn which noise comes from which part of the transport, e.g. motor vibration, belt-noise, step-pulley/eddy-brake noise, idler noise etc. As this thread highlights I view the belt as a big problem and most currently available ones to be less than acceptable (basically too tight). I’m testing a new one now which I think I like a lot. More on that in the future.

In other news my ‘buy it now button’ finger got the better of me and I caved in and bought a Retrotone top platter. The top platter has been the bane of my existence as I am hopelessly obsessive about this sort of thing and the smallest amount of run-out just triggers me in a way that is not healthy. My original top platter was obviously a ‘Friday afternoon’ job as it isn’t damaged, just badly machined, especially on the chamfer. It should never have got out of the factory. I replaced it with a Swissonor one, which is vastly better, but still not 100% right. I’d say it has about 0.3-0.4mm run-out. In the world of TD-124 top platters that is bloody good (just look at Ken Micallef’s!), but me? Triggered. It just winds me up. I respect that it is an exceptionally hard thing to make, and they make it as Thorens made it, so I’m not knocking it. It is what it is. The Retrotone is something else entirely. It is machined from a solid billet of aluminium, is a fair bit heavier and slightly taller. Most importantly it is flat! The run-out is not visible to me, and trust me I know how to look! I think it may sound better too, lower noise-floor and more solid, but it is a hard one to assess as changing it takes a very long time (involving unscrewing and transferring the 45 adapter centre and mat, resetting VTA etc).

I’m listening to Hania Rani’s Live from S2 now and it sounds superb, really nice solid piano, deep bass, lovely vocal etc. It certainly hasn’t broken anything. I also got the mat adapter and cork inner thingy, but I’m not using those at present. I used a 5% code on eBay which made me feel a little better! I need to slightly adjust the clutch at sometime as it rubs a bit (i.e. the clutch needs to go up a smidge), but I don’t use it so that can wait until I next do an oil or belt change.

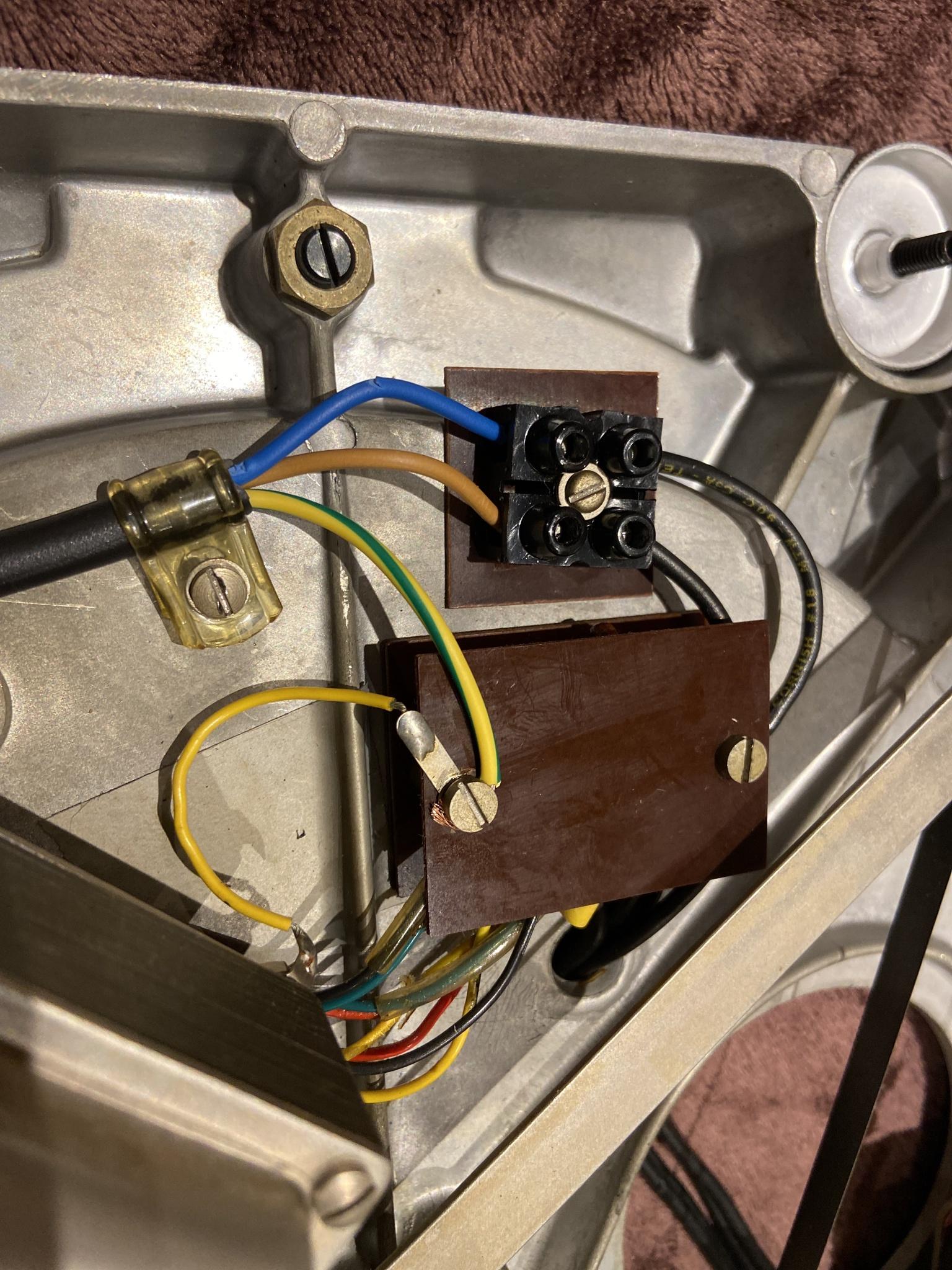

PS Current state of play: Stereo Lab plinth, Shopper main bearing and armboard, Audio Silente sintered motor, step-pulley and idler bushings, Hanze-Fi motor springs, prototype belt, green iron sub-platter, Retrotone top-platter. Rather more modded/further from stock than I’d have ideally liked, but it is working very nicely indeed.