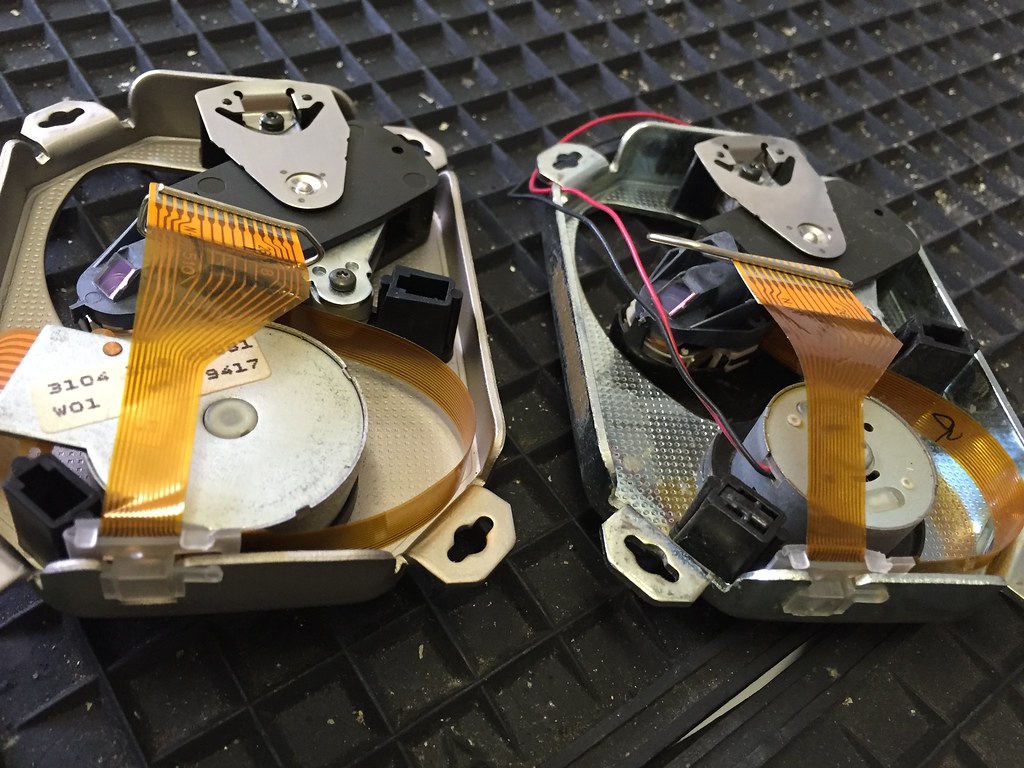

Refitting original laser returns fault to original. Two short spin motor pulses as it tries to read TOC, with stop/play LEDs flashing in sync (and main display goinging off when the stop or play LED is lit). Behaviour exactly same either with or without disc inserted.

I've checked all voltages and signals on the servo board as it tries to read TOC - and to my completely untrained eye/knowledge (I was never much good at this when I was paid for it - 30 years in technology have not helped

) all looks OK. Supply lines at all relevant pins on the 8808 and 8809, driver opamps same. Signal lines rise and fall in time with the motor pulses/laser focus attempts.

At this stage I have to rule out the laser itself and get a known good CDM 9 before going any further - for all I know I just swapped a poor laser for an even sicker one...

So, off to setup some eBay searches

Some photos;

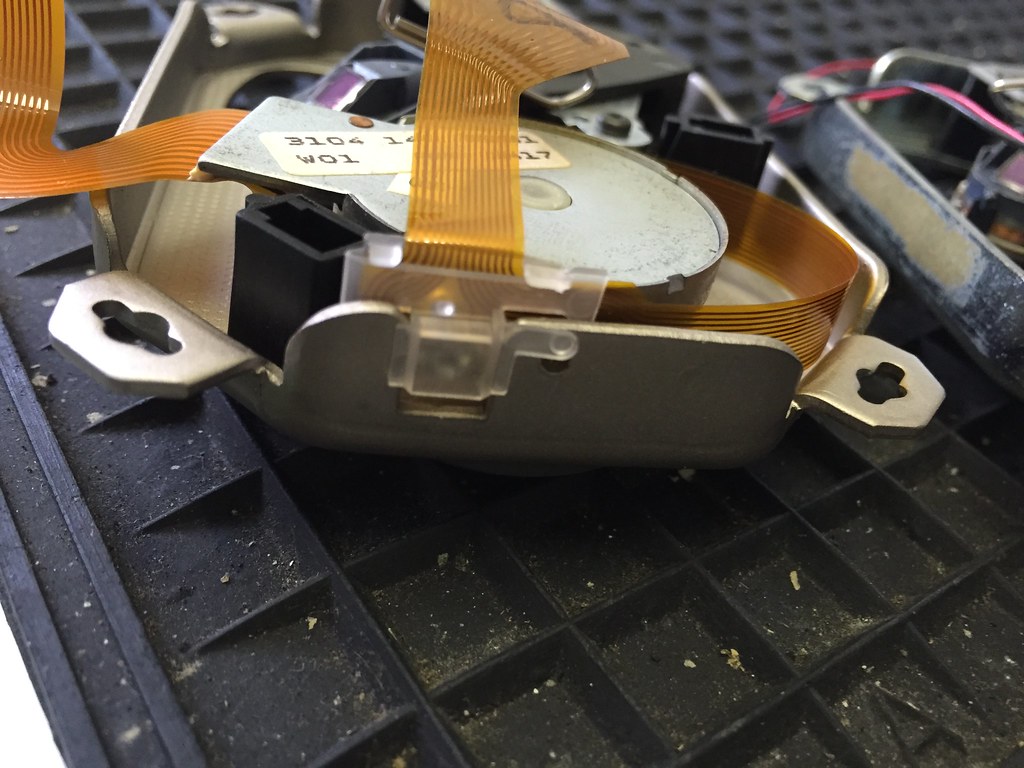

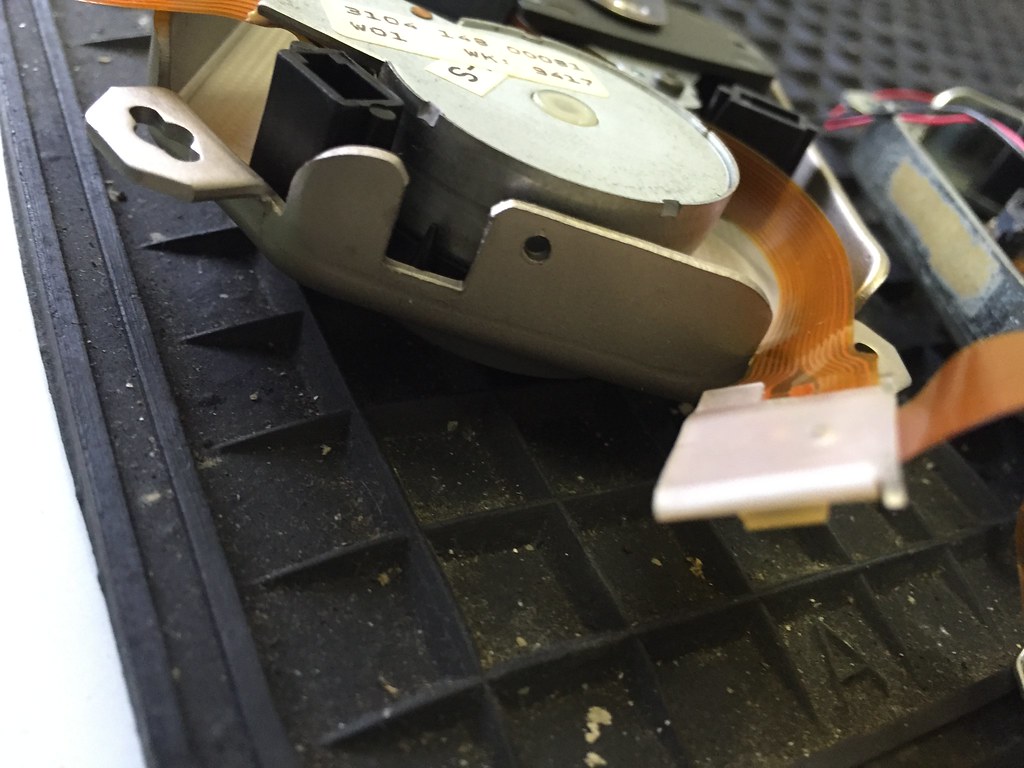

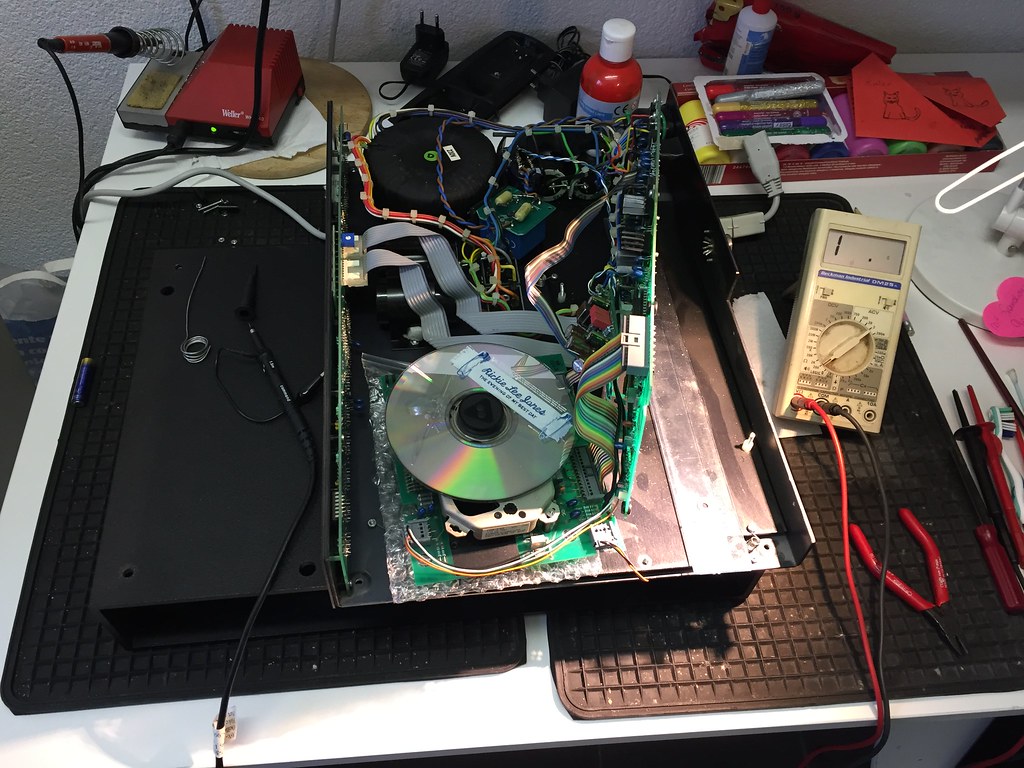

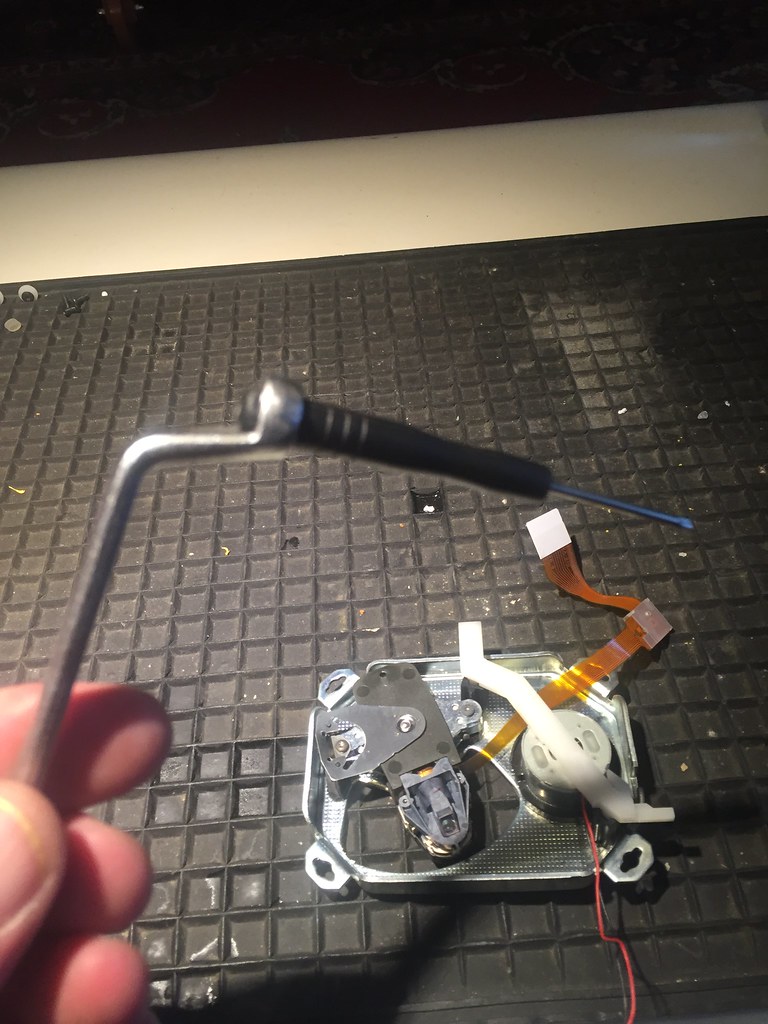

Just able to work on it - either with main PCB mounted and mech flipped vertically, or like this;

Minimalist mounting to give maximum access;

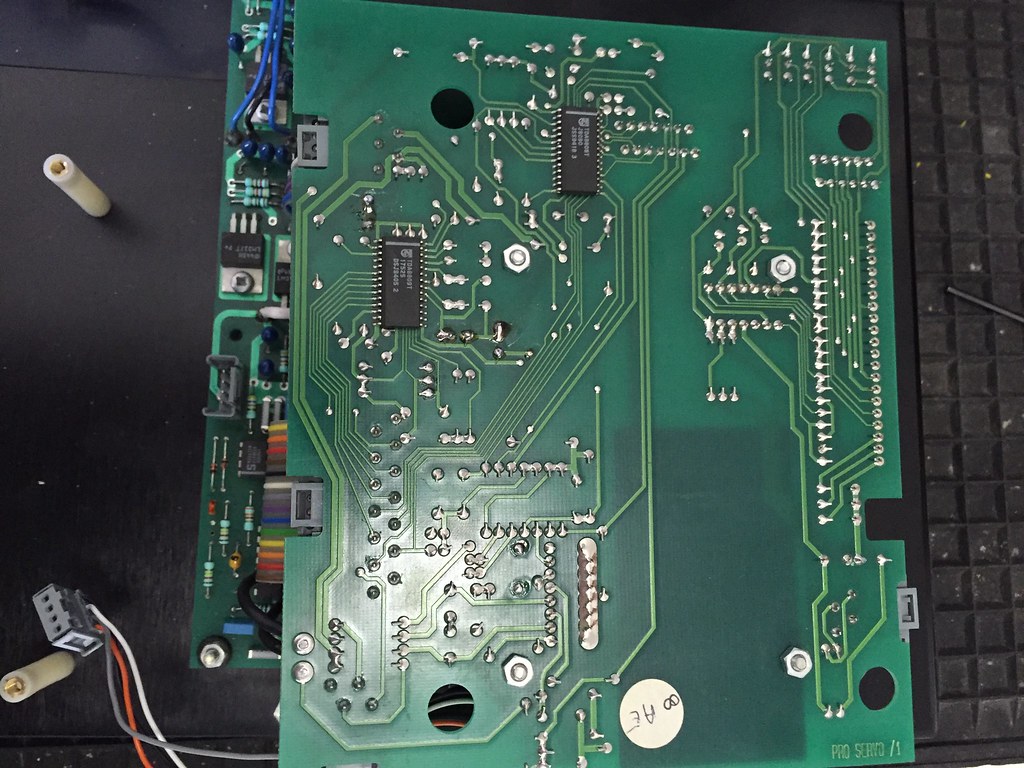

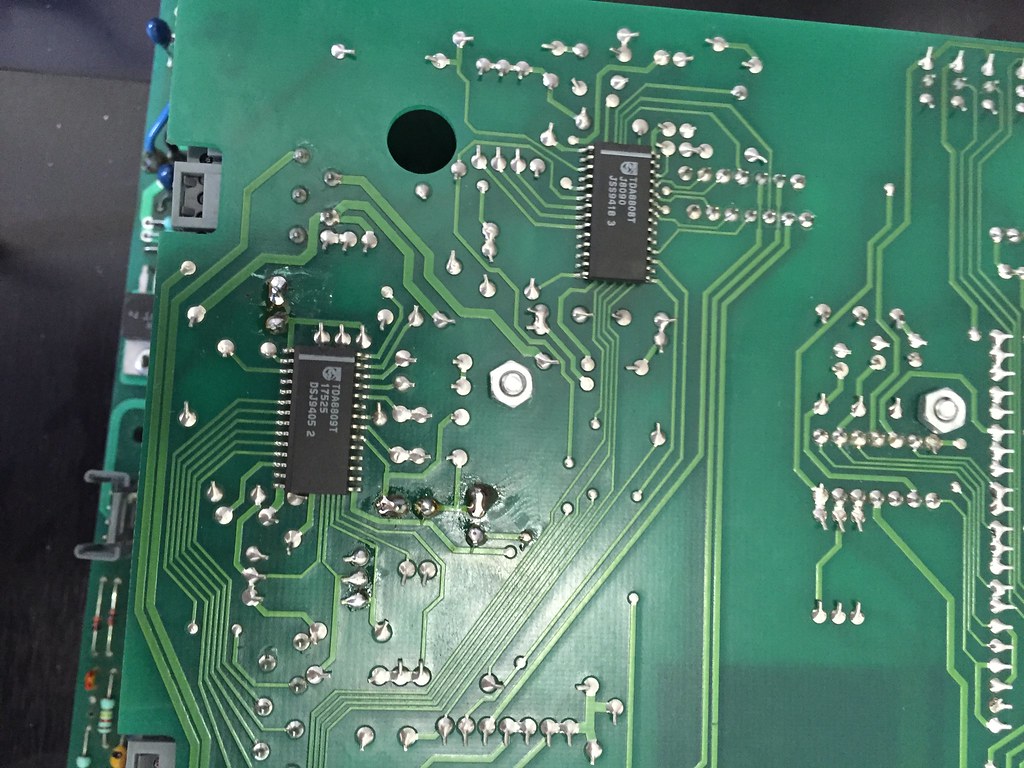

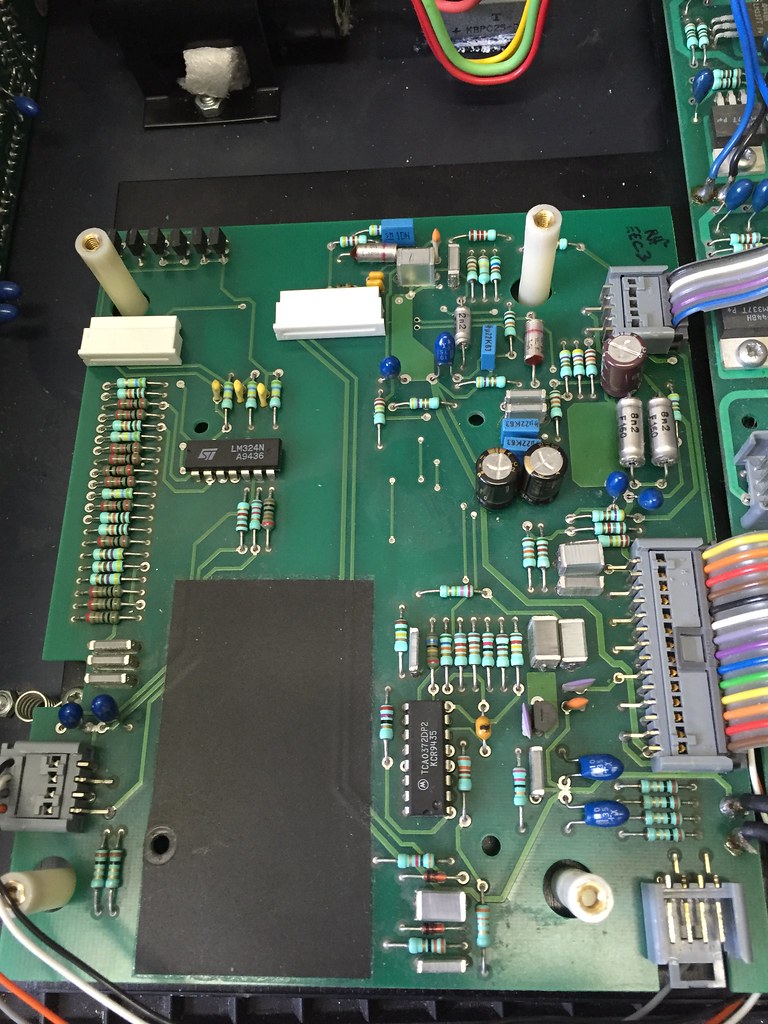

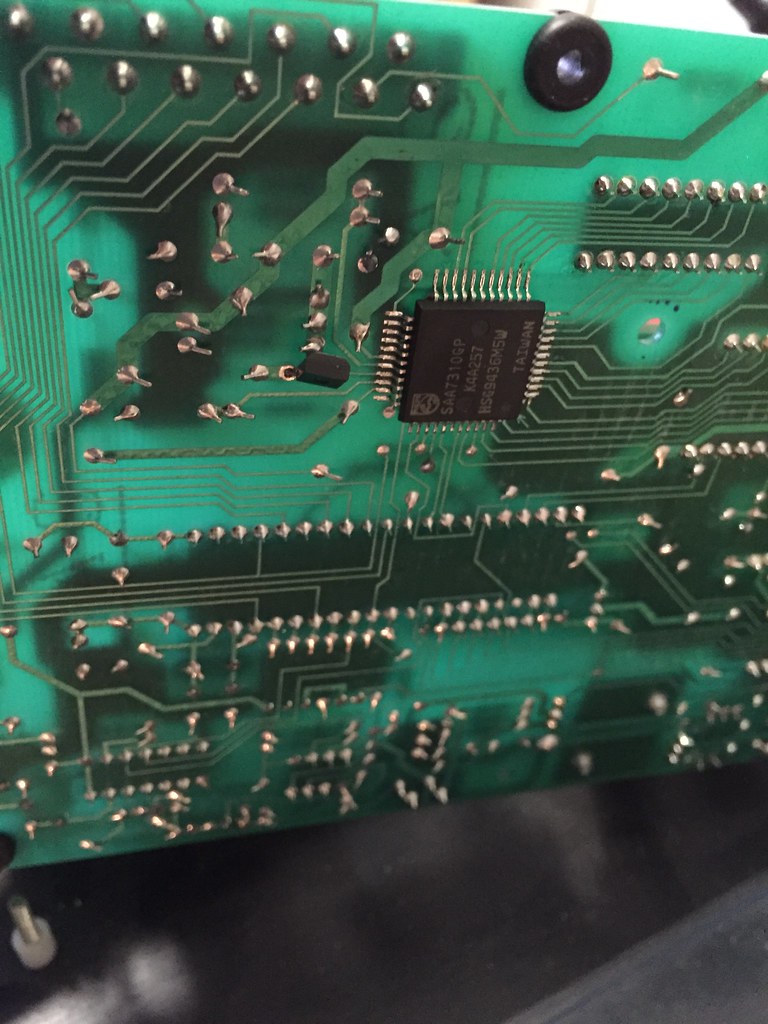

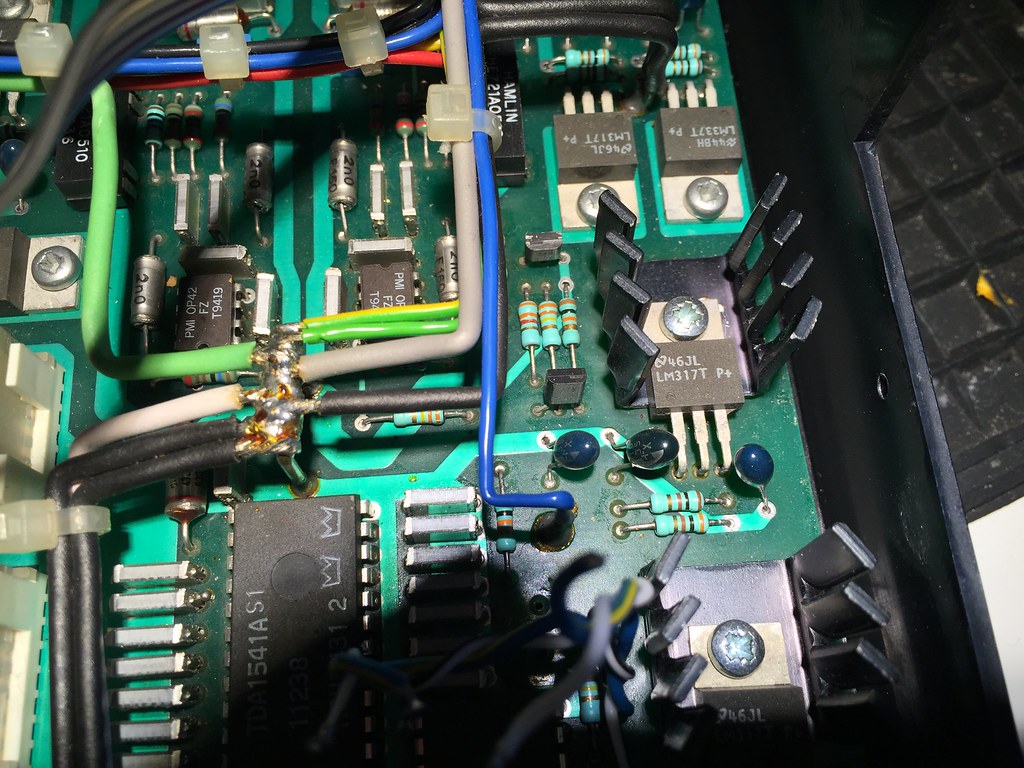

Main area I played with - I removed 2 caps and the original crystal, plus pulled a pin of the 7220 out of board and putl Flea's second feed at its output to the SAA7310

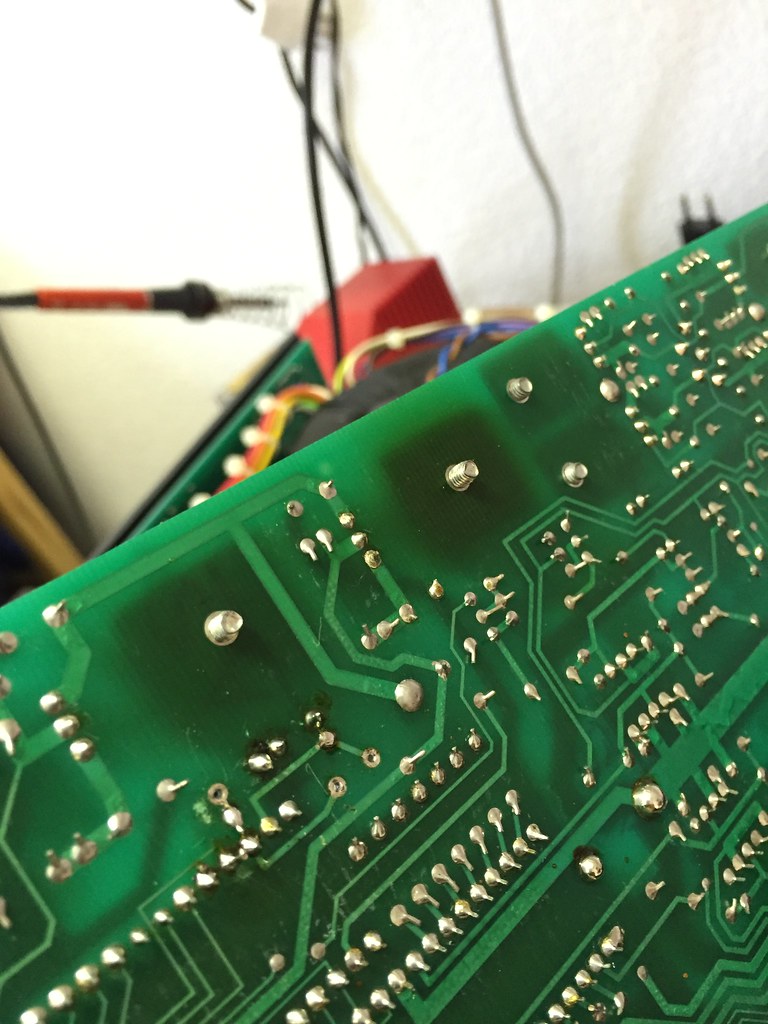

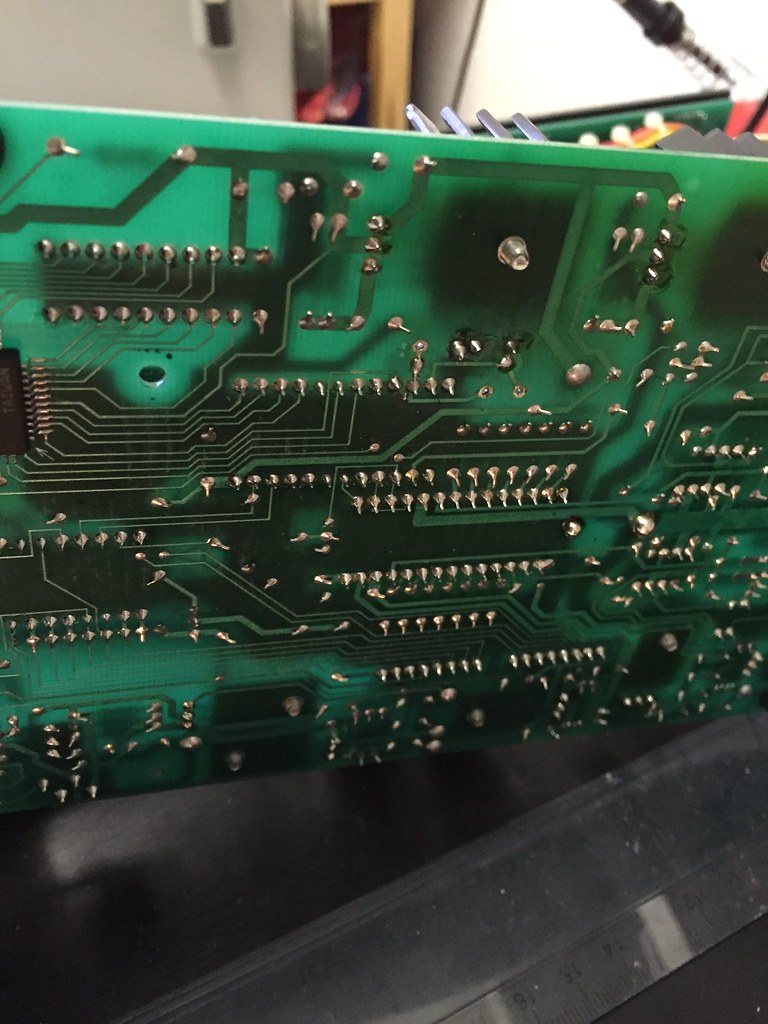

Some of the LM317 regulator joints looked cooked, and I was hopeful I had missed a failed one...but not, continuity still good - I just reflowed them all.

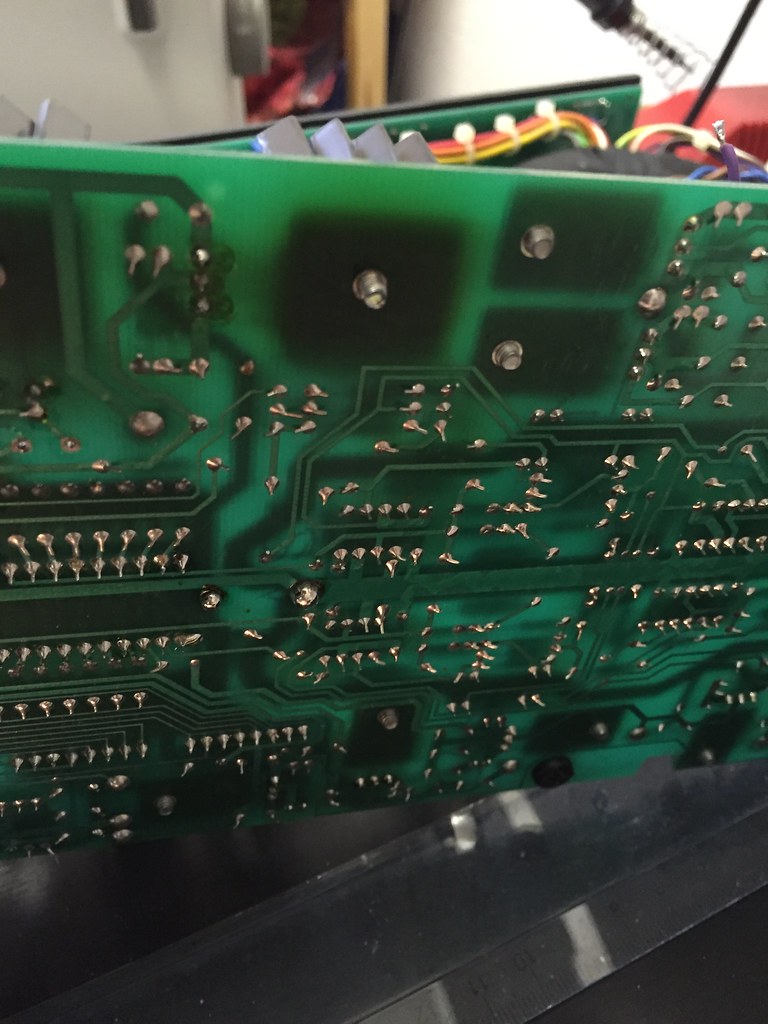

Bottom of main PCB;

Richard

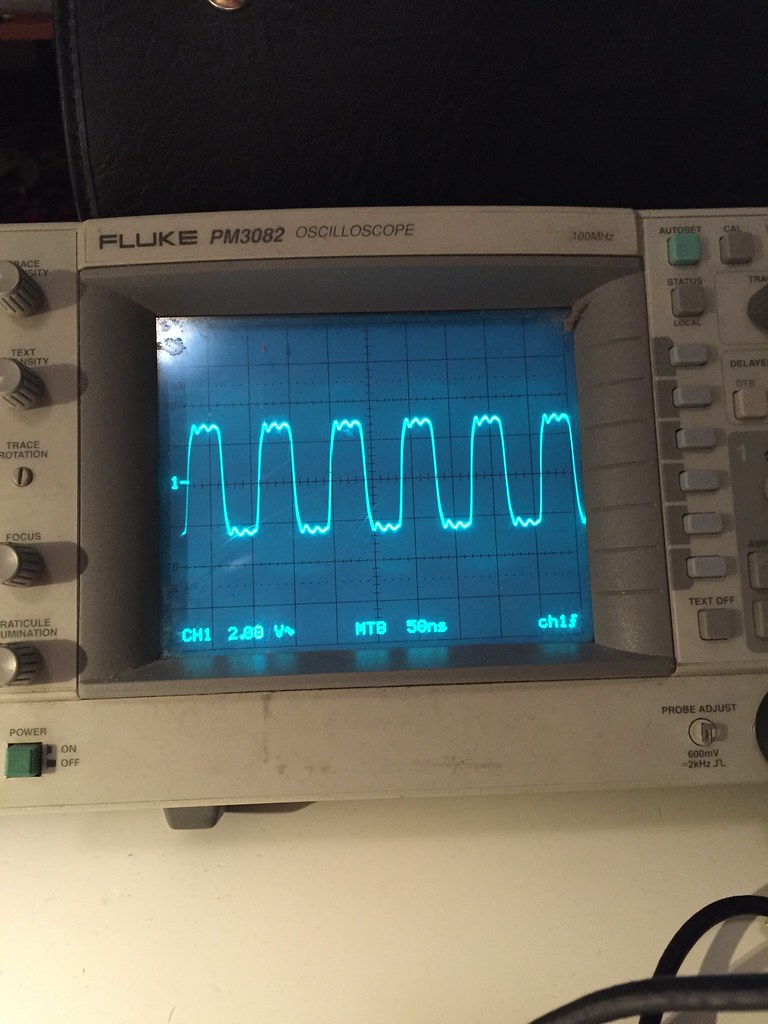

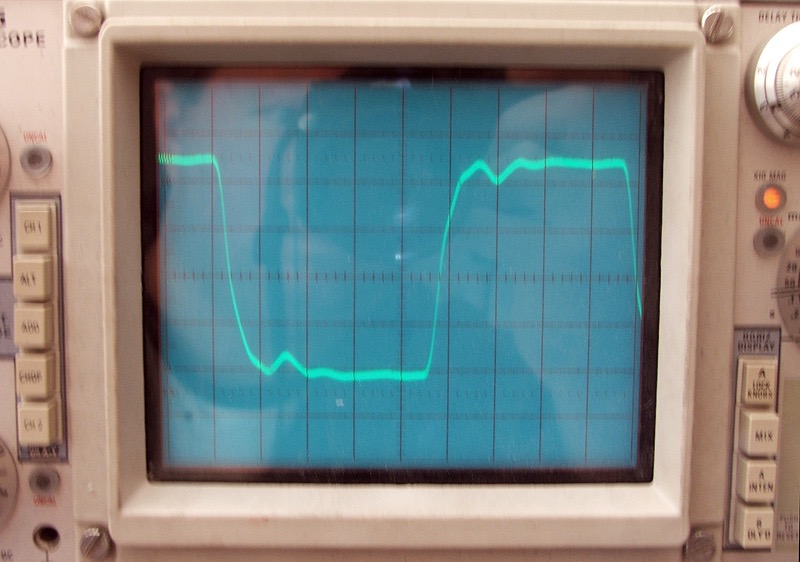

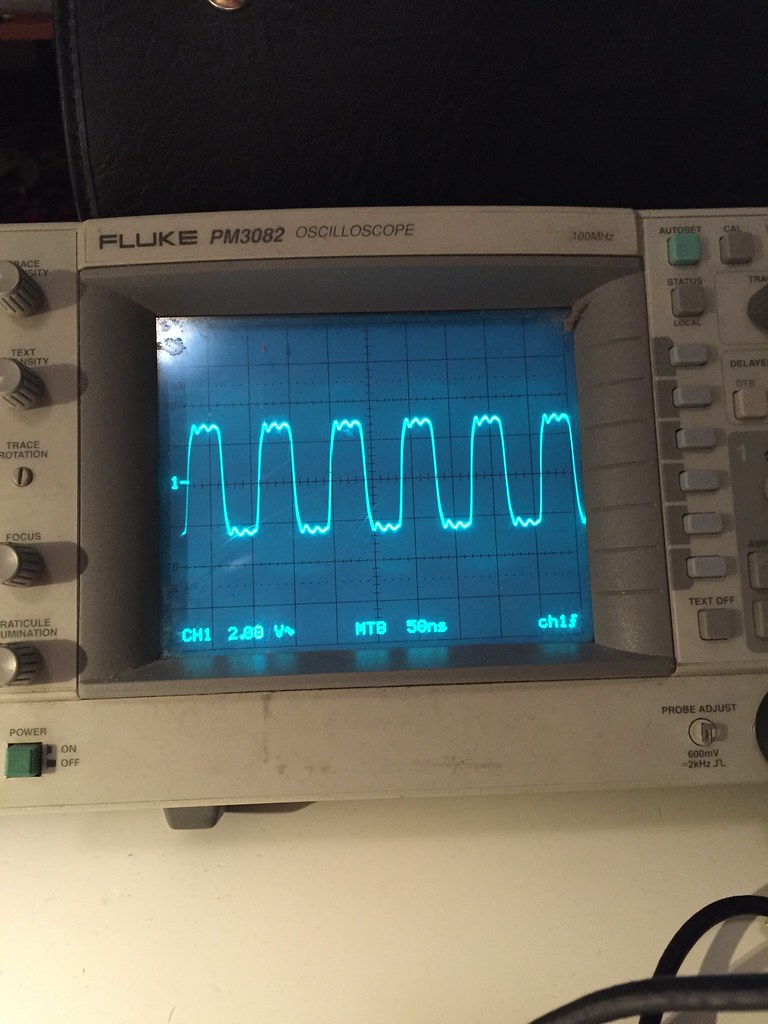

Flea oscillator is running, but is it supposed to look like this?

Flea oscillator is running, but is it supposed to look like this?

5v out from reg on Flea OK, so I assume normal, and just looks horrible?

5v out from reg on Flea OK, so I assume normal, and just looks horrible?