James

Lord of the Erg\o/s

Option 2 will exhibit lower compliance and probably more effective at isolation.

From another thread ...

From another thread ...

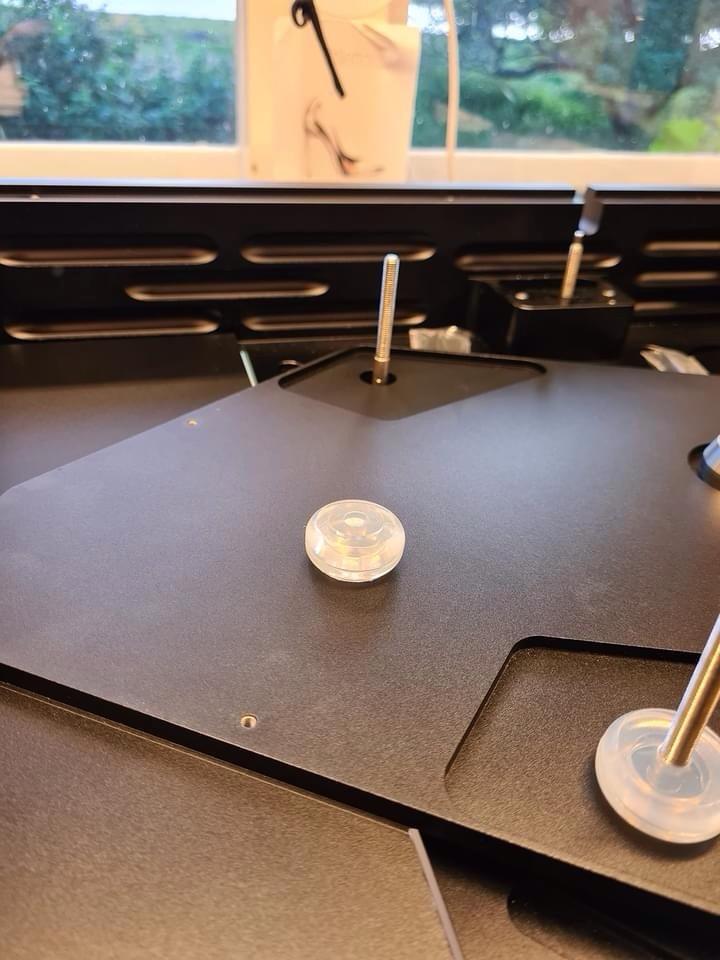

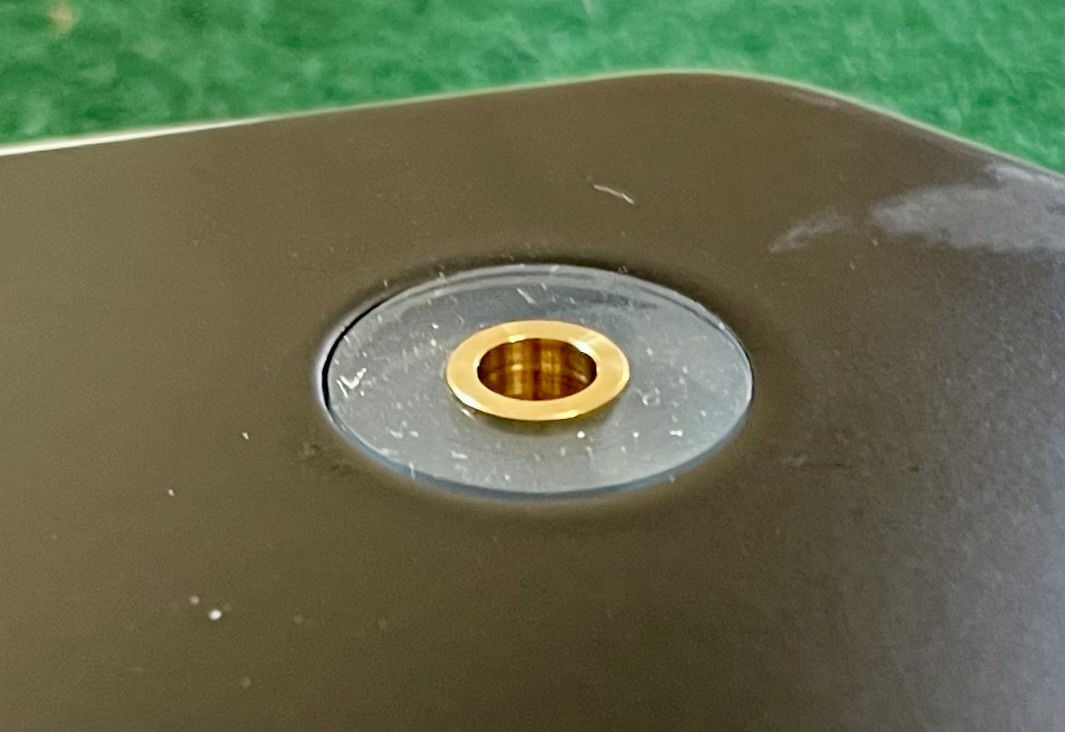

I’ve been looking into the silicone mushrooms with a view to trying them out, I think rather than being a specific part ‘made in Japan’ for the Thorens 124, they are a generic isolation product for PCBs with the brass collar removed:

These can be purchased for £10.72 from RS components, the manufacturer is Taica corporation of Japan

https://taica.co.jp/gel/en/product/vibration_damping/gelbush.html

The 14mm size is more suited to the LP12 sub-chassis, the Thorens are normally 16mm and a different shape.