sq225917

Bit of this, bit of that

Phixphi, lot's of Ac controllers drop the voltage to make things run as smoothly as possible. Some do it because the phase lag isn't set accurately for the particular motor, just for a nominal value for that motor type. Others do it because it helps reduce the magnetic field intensity and therefore reduces cogging.

Personally I like the idea of adding viscous drag, this smooths the motor, reduces cogging due to the added load collapsing the field a little and you retain torque so stylus drag will never become an issue. Also because the drag created by the fluid is speed dependant the drag applied increases whenever speed does and decreases whenever speed do, so it auto-tracks any small changes in speed at the bearing, effectively under and over damping as required.

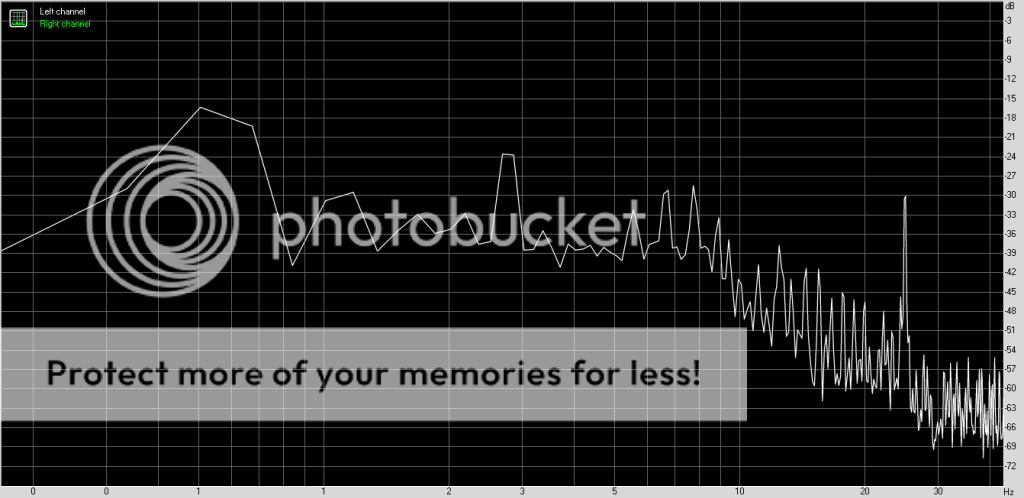

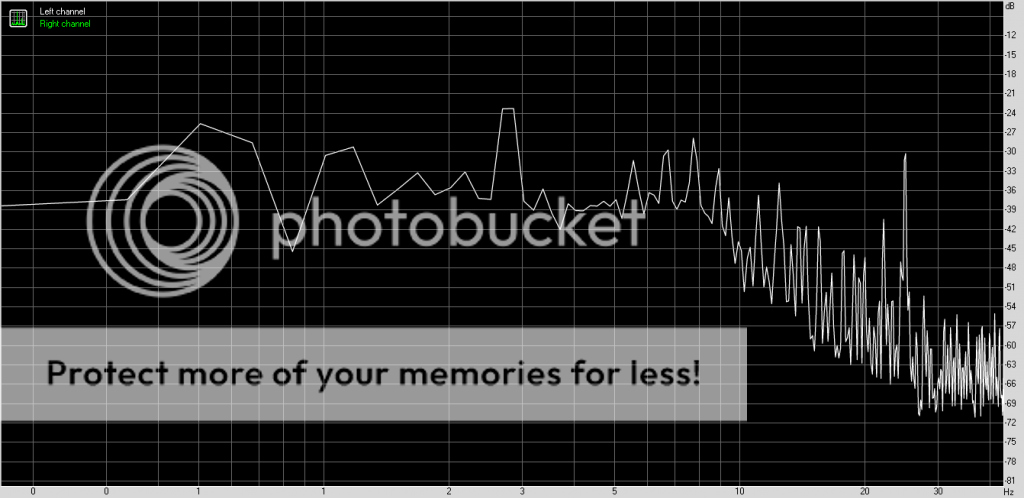

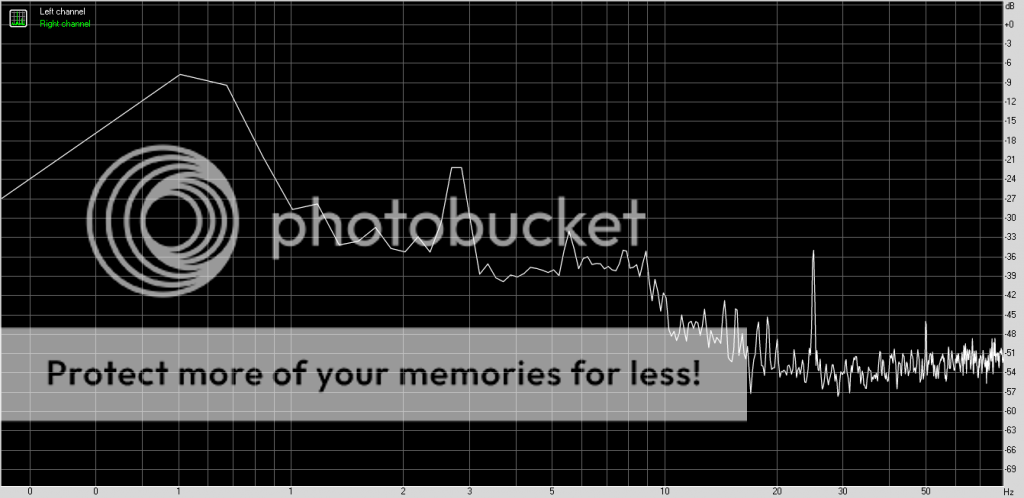

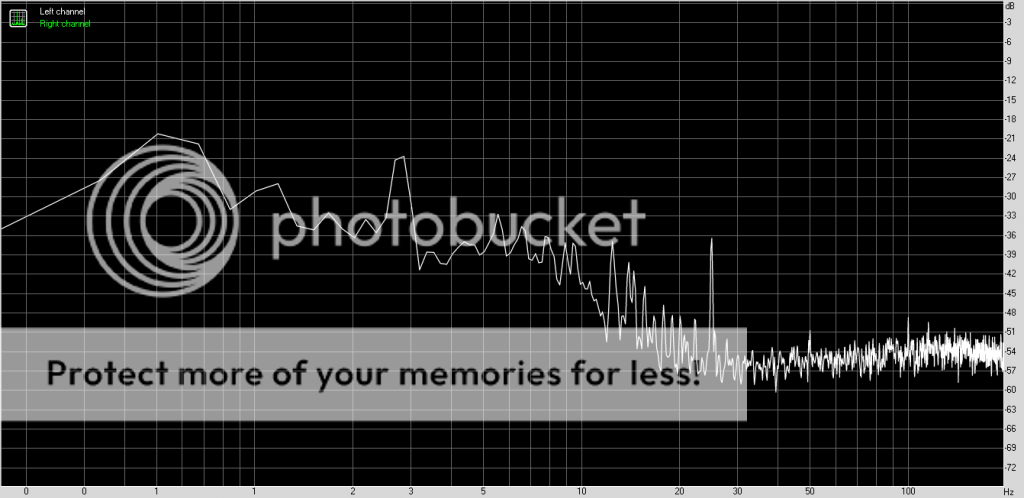

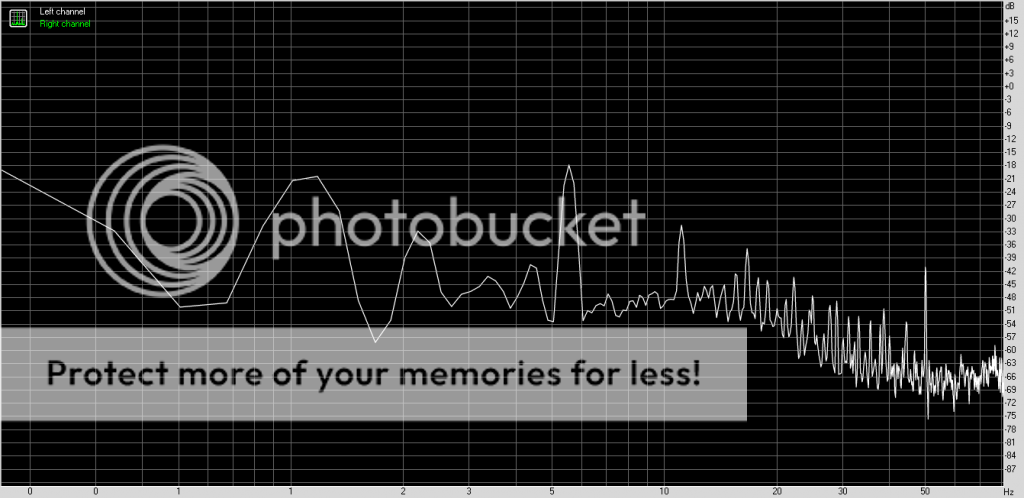

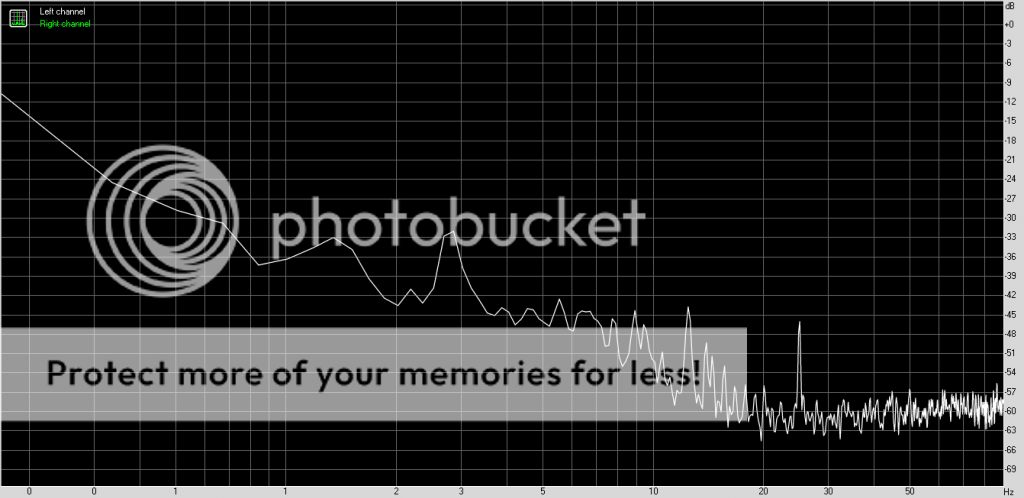

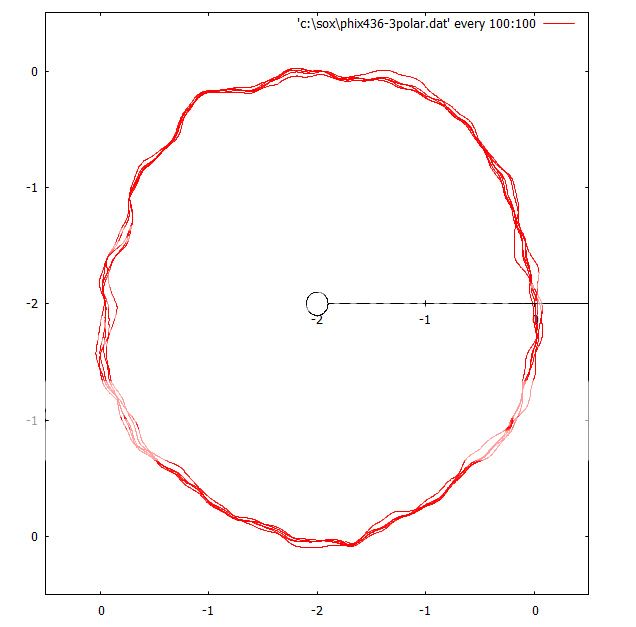

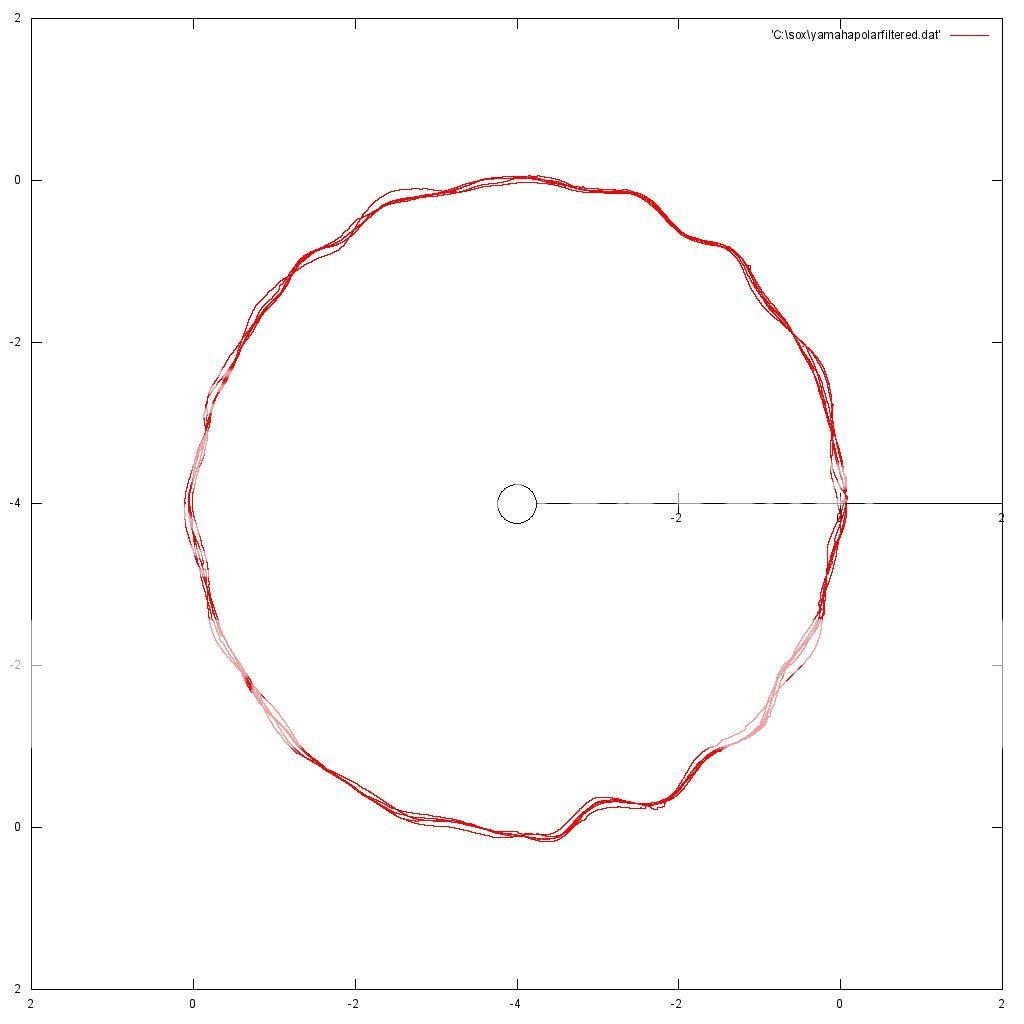

I tried simple capacitor shift, a Valhalla, a Lingo 1 and a Hercules, none of them sounded as good or measured as smoothly as a simple Geddon clone with 'sticky' bearing oil.

Personally I like the idea of adding viscous drag, this smooths the motor, reduces cogging due to the added load collapsing the field a little and you retain torque so stylus drag will never become an issue. Also because the drag created by the fluid is speed dependant the drag applied increases whenever speed does and decreases whenever speed do, so it auto-tracks any small changes in speed at the bearing, effectively under and over damping as required.

I tried simple capacitor shift, a Valhalla, a Lingo 1 and a Hercules, none of them sounded as good or measured as smoothly as a simple Geddon clone with 'sticky' bearing oil.