Are you making some assumption about where the difference comes from in each measurement? Could there be more than one variable at play, friction, idler height, angular offset potential, tension of locking nut......?

Sq, all files were taken at the same run, after 1h+ warump, under the same ambient cond. I do not think there are really different variables in the play apart from the teflon + LP centering--there is very little I could possibly change (see below). The top clip washer (not a nut!) has no way to adjust--it just clips into the idler spindle groove and that's it. It's something like that:

http://www.gasgoo.com/auto-products/universal-parts-301/1288821.html

and I think I've erroneously called it a "locking washer". Sorry. Angular offset is the holiest cow I do not dare to touch after the EMT service (I've been exchanging all the washers very gently, trying not to push the idler much, it sits at ~3.5mm steel spindle fixed to a ~4mm steel plate..not easy to bent).

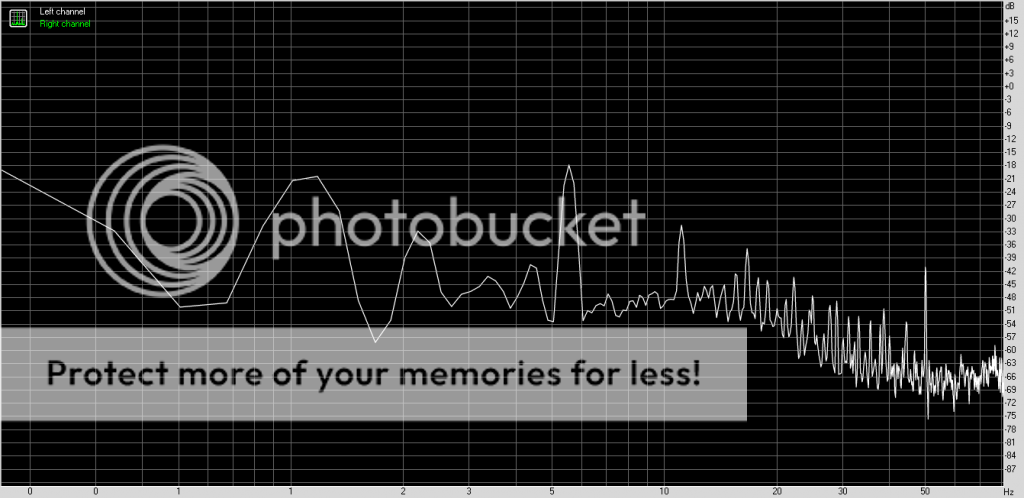

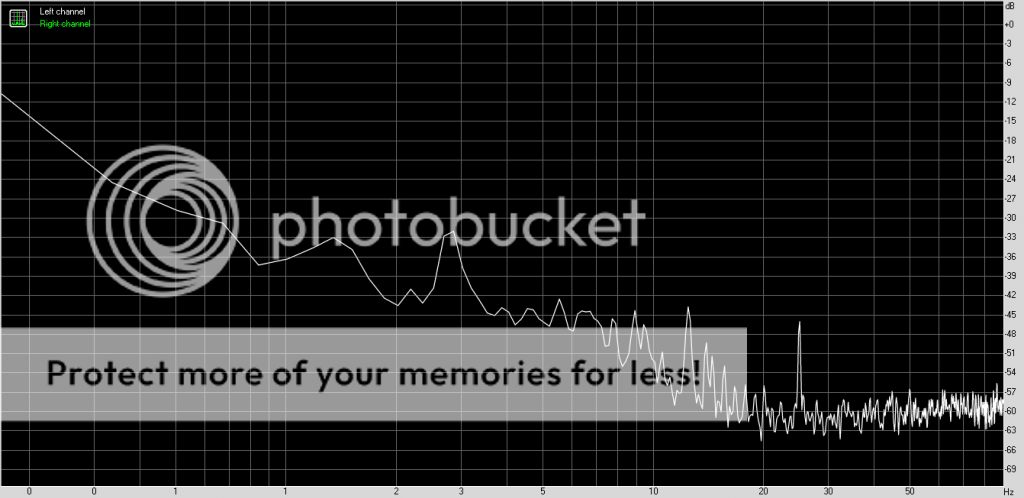

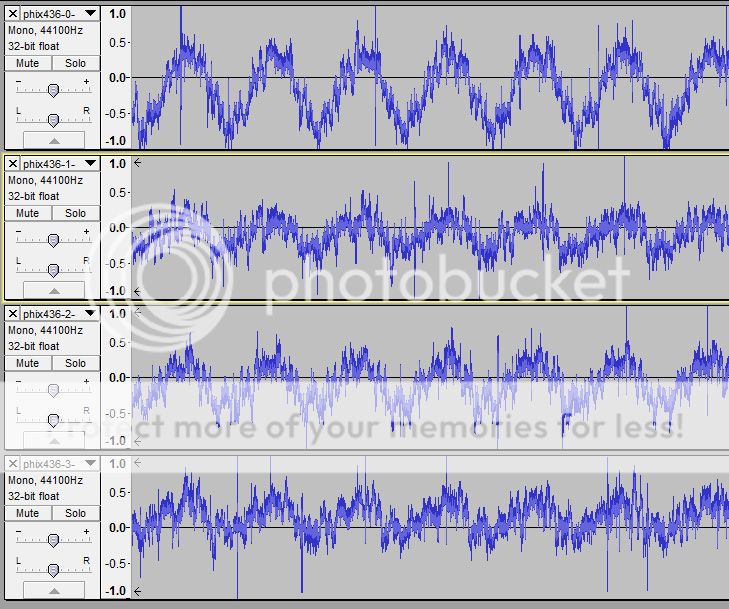

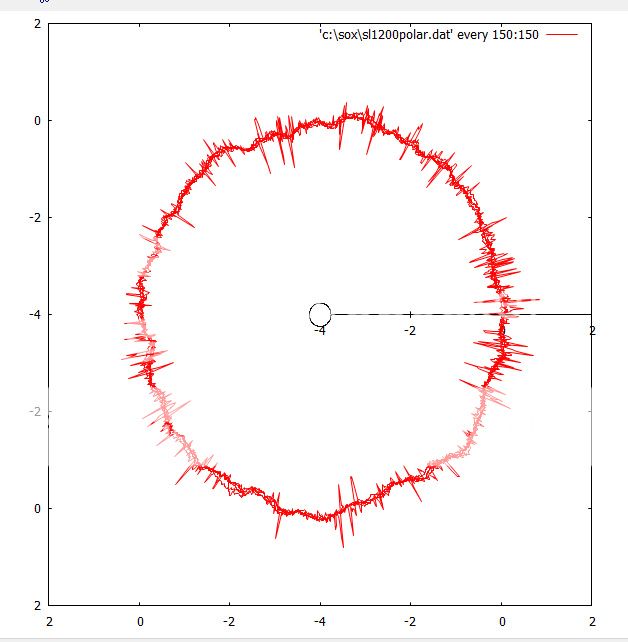

The teflon is +/- 0.3mm so the idler position is changed by 0.6mm at max (two teflons on top) and it's vertical travel by at max 0.9mm (all there teflons in place). What I suspect is that the idler travels upwards, bounces back and goes downwards, touching the bottom fiber washer, then going up again etc. This is based on an observation that with no smoothing teflon washers, the clip washer on top is periodicaly engaged in the rotation (the idler pressing it from below, when reaching the top position?) and then disengaged (the idler traveling downward and probably working against the lower fiber washer?). With the teflon below the idler only, this still happens but much rarely--the clip washer is most of the time engaged in the rotation, stopping only occasionaly for a very short time. This is probably due to the added 0.3mm at the bottom, limiting the idler vertical travel. If what I measure is credible,

if, than this means that smoothing the idler work against the bottom fiber washer (as per the original trick by the Lencoheaven Dmitri) is more important than smoothing the work agianst the upper clip washer. What I may try is adding a second teflon on bottom, netting in 0.6mm limiting of the idler vert. travel.

Here is a pic of the idler, with the top fiber & clip washers clerly visible:

http://www.mediafire.com/?u4whr2bzav8n09h