Nagraboy

Ausculta fili

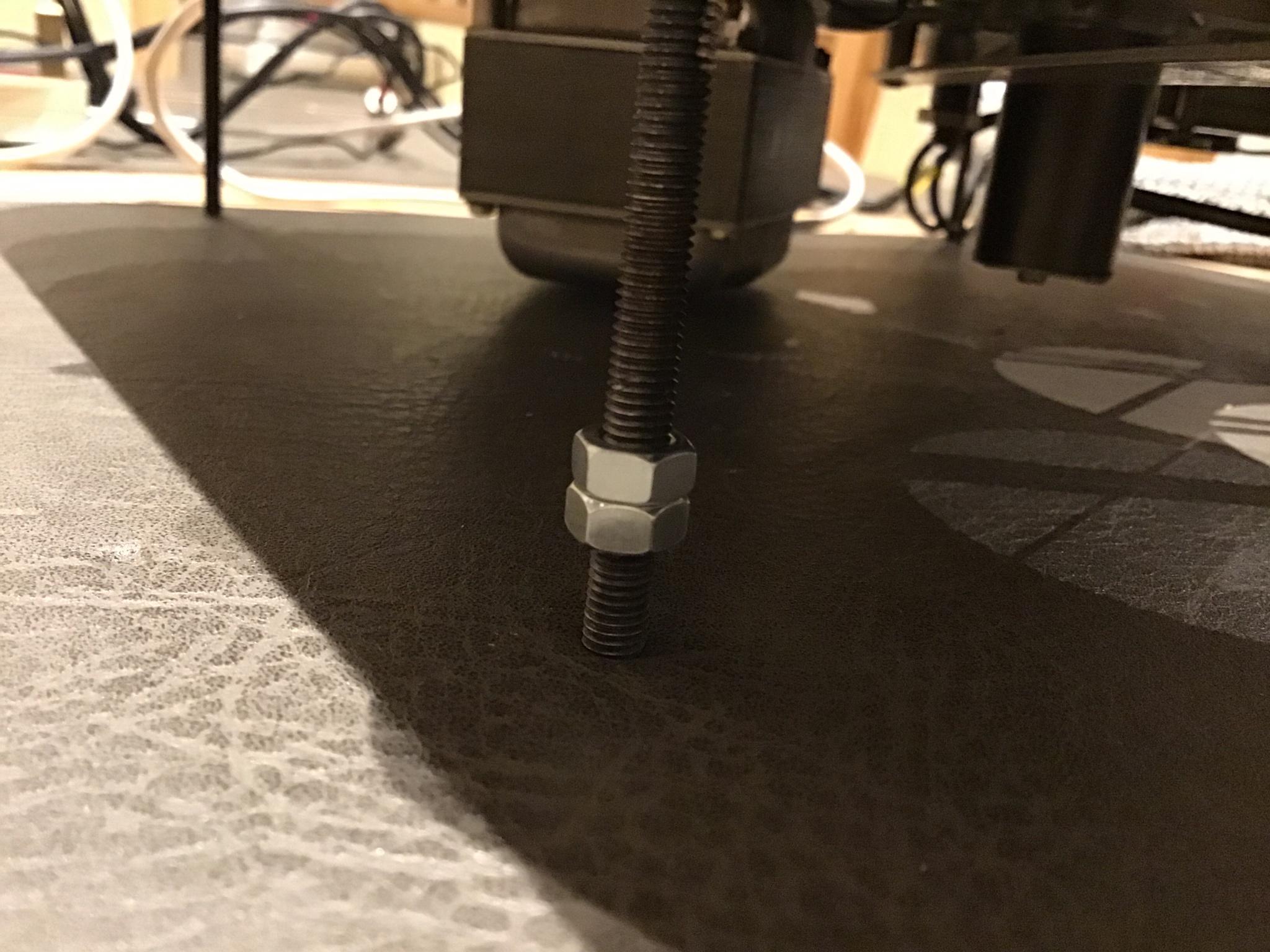

You’re right Tony, twisting them has slightly improved the allignment.

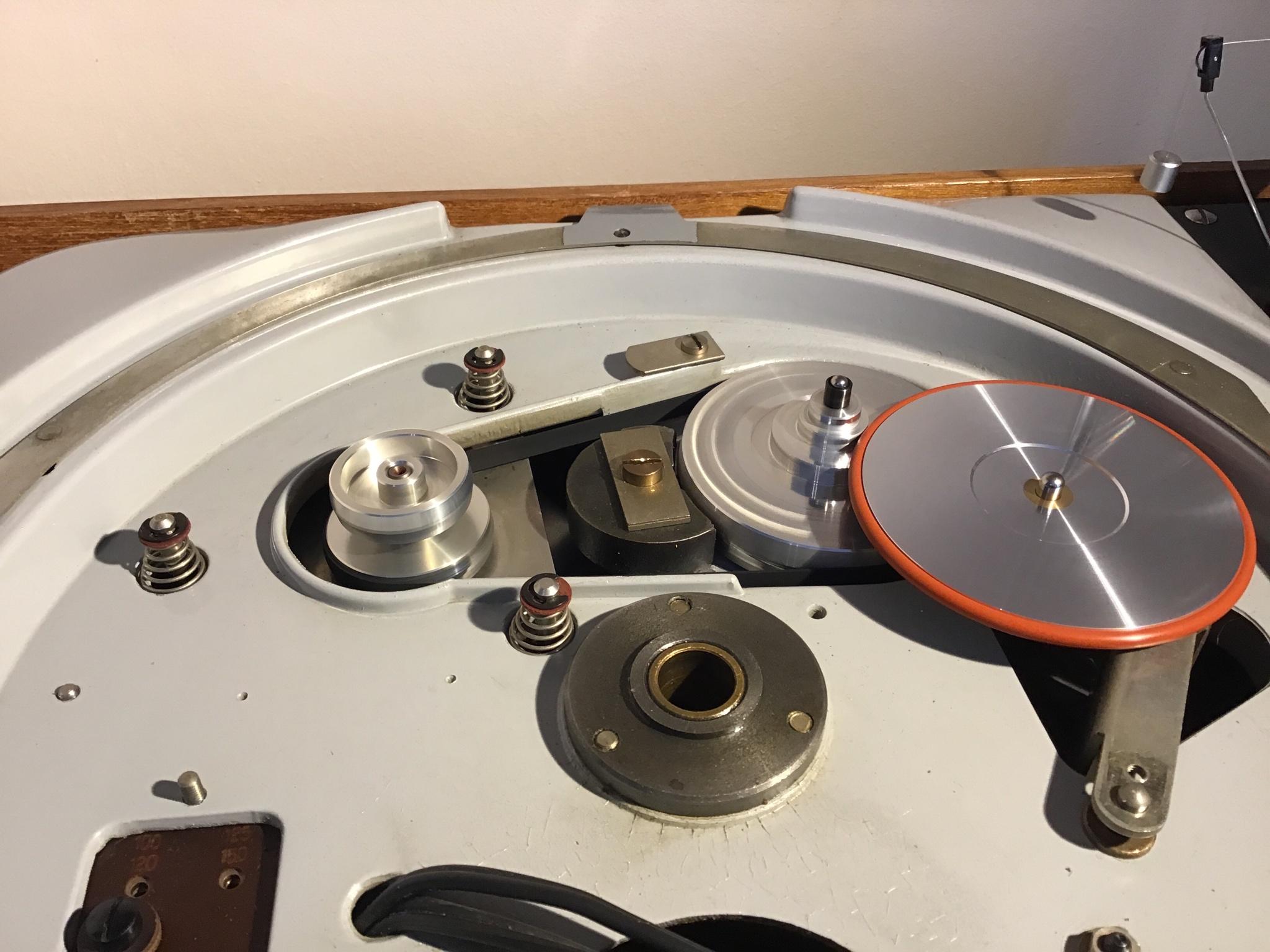

So I’ve now got the Hanze belt and springs fitted. I think some low frequency noise had been reduced but still easily audible higher frequency noise is present. I think the step pulley might be a source of that. Anyway, time to fit the new idler wheel…

So I’ve now got the Hanze belt and springs fitted. I think some low frequency noise had been reduced but still easily audible higher frequency noise is present. I think the step pulley might be a source of that. Anyway, time to fit the new idler wheel…