You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Screw length needed to hold in brick behind lathe & plaster

- Thread starter ToTo Man

- Start date

gintonic

50 shades of grey pussy cats

I am rather enjoying this thread, gently eccentric and at the same time mildly educational.

I blame neoliberalism and lurch rightward of otherwise nicely central panel fixings, to the revolution!

you know where money comes from?

martin clark

pinko bodger

I think through the wall to a 12" spreader plate on each corner . Better make that 18" . You're the structural guy here martin, can we get away with M12 studding or should we go to M14?

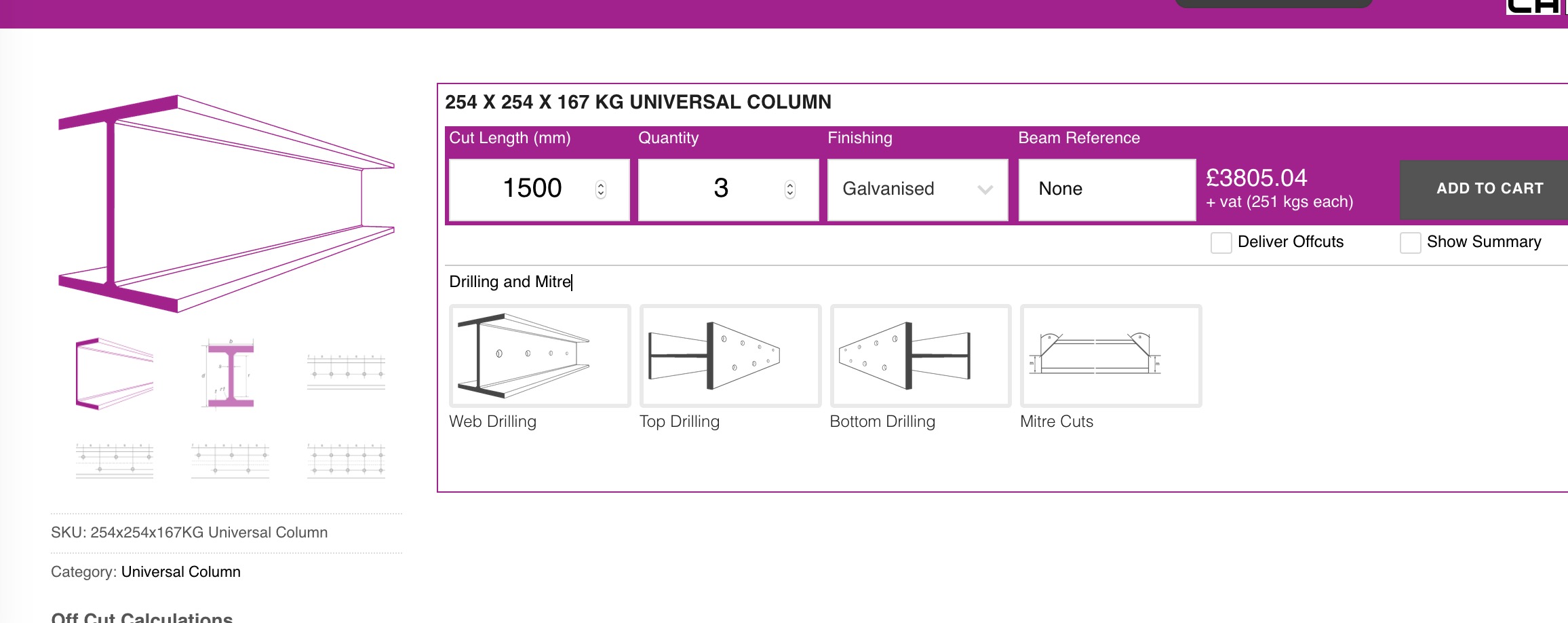

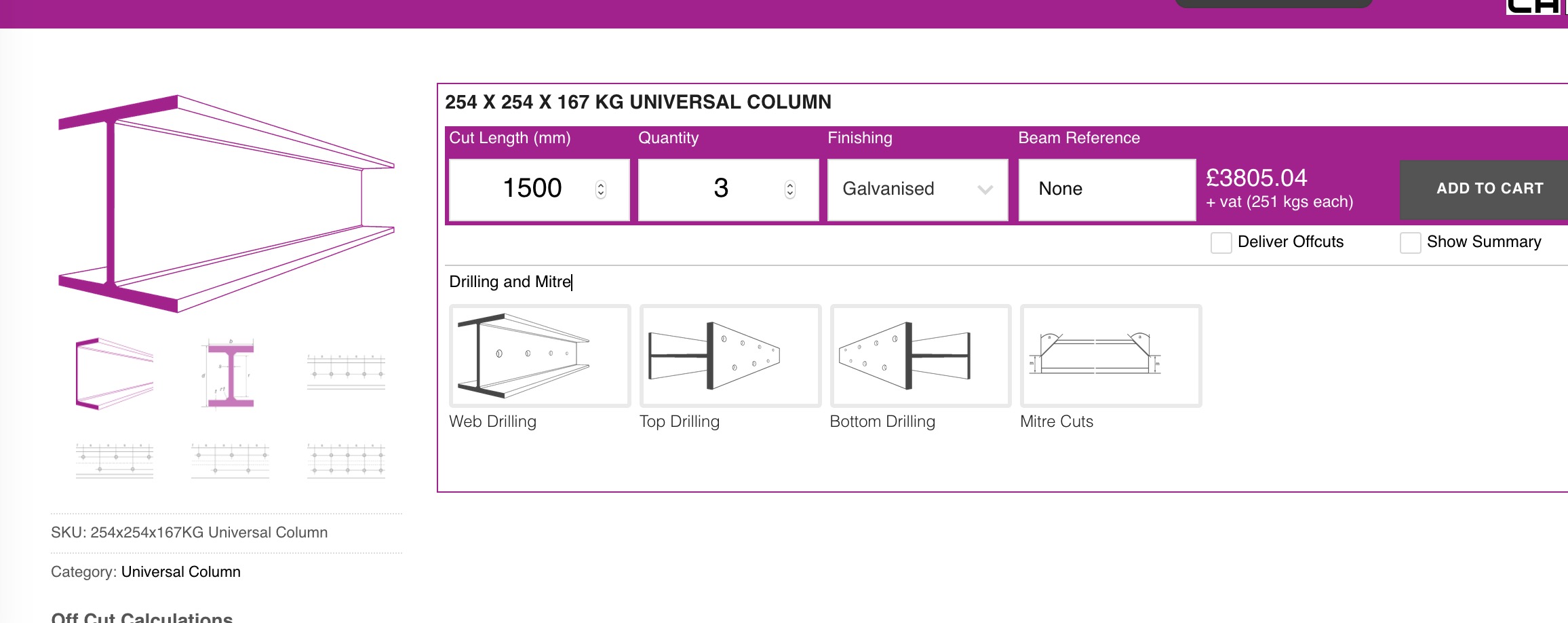

Given we have already piled, capped piles, built min 254 x 254 x UC147 goalpost framework to support the telly - it''d be a shame to not also use it with M18 stud into 450 x 450 spreaders to restrain that dodgy brick wall behind.

Sunk costs, and all that...

Im really looking forward to when we start using 12mm re-bar set into 300mm thick studwork void and filling with superfluid C40 concrete.

That should just about hold up the required 9Kg load.

It would need at least 28 days to fully cure though, which is a bit unfortunate.

But this on top of Martins piles, well, it should just about work.

That should just about hold up the required 9Kg load.

It would need at least 28 days to fully cure though, which is a bit unfortunate.

But this on top of Martins piles, well, it should just about work.

Yes, you're right. M18 it is, haporth of tar and all that. After all, imagine if that 9kg broke loose.Given we have already piled, capped piles, built min 254 x 254 x UC147 goalpost framework to support the telly - it''d be a shame to not also use it with M18 stud into 450 x 450 spreaders to restrain that dodgy brick wall behind.

Sunk costs, and all that...

corefix, comes in 100 120 or 150mm lengths

https://www.amazon.co.uk/dp/B082WF23TY/?tag=pinkfishmedia-21

https://www.amazon.co.uk/dp/B082WF23TY/?tag=pinkfishmedia-21

This site contains affiliate links for which pink fish media may be compensated.

martin clark

pinko bodger

+1 to this post - except, just to disambiguate : I don't have piles... it was a recommendation based on the load case.Im really looking forward to when we start using 12mm re-bar set into 300mm thick studwork void and filling with superfluid C40 concrete. That should just about hold up the required 9Kg load. It would need at least 28 days to fully cure though, which is a bit unfortunate.

But this on top of Martins piles, well, it should just about work.

Left hand or right hand thread?I can’t believe nobody has recommended sky hooks.

Pete

gintonic

50 shades of grey pussy cats

I can’t believe nobody has recommended sky hooks.

Pete

they are already holding the house up

Pete MB&D

Pete Maddex, the one and only!

As you well know it depends on the coriolis effect.Left hand or right hand thread?

Pete

cutting42

Arrived at B4 Hacker Ergo

Left hand or right hand thread?

both

https://www.google.com/search?q=bid...bih=720&dpr=2#imgrc=2voKj9ee7nTonM&lnspr=W10=

That's cool. I'm not sure what the point is, but it's a great bit of engineering.

GavinA

pfm Member

This is exactly what you need. I used something similar, but without the steel tube, to hold up a Habitat CD rack holding 355 opera boxes (ie including booklets) on a lath and plaster external wall. I don’t know what that weighs, but it will be a lot, and it’s still solidly attached after some years. I think the steel tube is probably a good addition. Lath and plaster will be thicker than plasterboard on dabs, so the next size up in length would be sensible to ensure adequate penetration of the brickwork.corefix, comes in 100 120 or 150mm lengths

https://www.amazon.co.uk/dp/B082WF23TY/?tag=pinkfishmedia-21

This site contains affiliate links for which pink fish media may be compensated.

Pete MB&D

Pete Maddex, the one and only!

Righty tighty righty loosey

Pete

martin clark

pinko bodger

Well they are a real thing, but woefully under-rated for the OP's issue...I can’t believe nobody has recommended sky hooks.

Pete

Pic from 100Vs site: 27 oct 2022

ToTo Man

the band not the dog

I've tested a 5mm screw in the french cleats and they fit fine, however the 'countersunk' section of the head does protrude out from the bracket quite far. I've also tested a 5mm round-headed screw in the cleat and it seats better. I'm therefore going to purchase some 100mm round heads and use these with the rawl plugs and steel bridging sleeves that come with the Corefix screws. My question is: should I be looking for round heads with only a partially-threaded shaft or will a fully-threaded shaft do the job equally well?

Ted-M

pfm Member

My question is: should I be looking for round heads with only a partially-threaded shaft or will a fully-threaded shaft do the job equally well?

Either should be fine