ToTo Man

the band not the dog

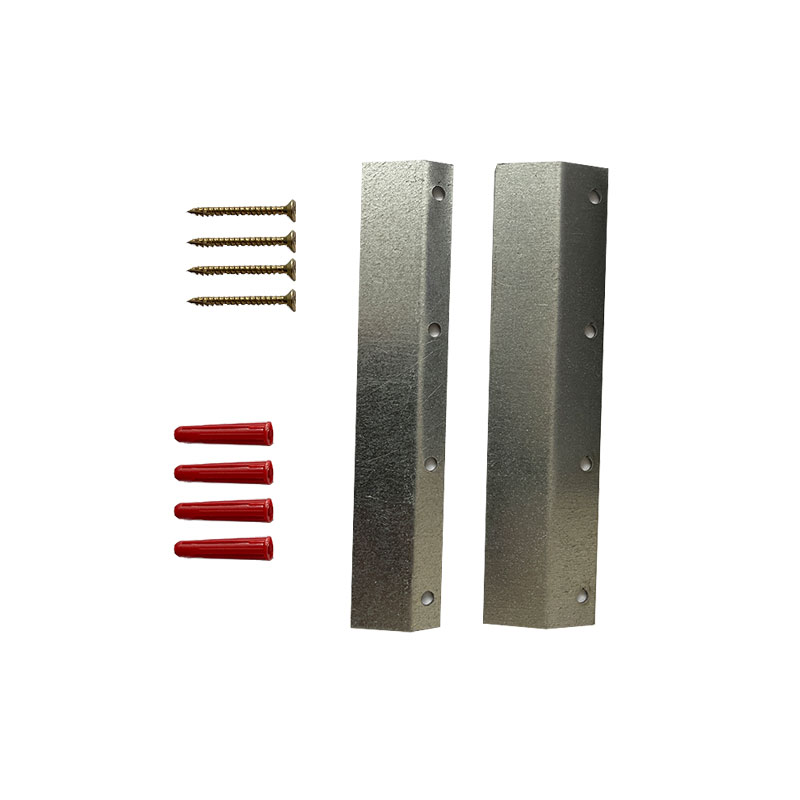

I'm attempting to hang some 9kg wooden diffuser wall panels that have been supplied with 15cm long french cleats that have 4 screw holes. I drilled a pilot hole to test the wall construction. It's 40mm from the front of the lathe & plaster to the brick wall behind, the air cavity between the two is probably 20mm-25mm.

I want to use screws and rawl plugs that are long enough to go through into the brickwork but I don't know how far into the brickwork they should go for a secure fit?. What would be sufficient if each screw is supporting 2.25kg?

EDIT - The size of the screw holes in the french cleats limits the diameter of screw I can use. The supplied screws and plugs just stop short of reaching the brick.

I want to use screws and rawl plugs that are long enough to go through into the brickwork but I don't know how far into the brickwork they should go for a secure fit?. What would be sufficient if each screw is supporting 2.25kg?

EDIT - The size of the screw holes in the french cleats limits the diameter of screw I can use. The supplied screws and plugs just stop short of reaching the brick.