Well, not if the claims that microphony is a non-problem are true, obviously...

Anyway, I thought the point here was that we weren't simply measuring the vibration, we were going to be measuring the output of the equipment when subject to, and not subject to, the vibrations from a musical signal. I realise that has been delayed due to non-availability of kit, but isn't it therefore premature to pronounce any vibration currently measured as being tiny. It may be tiny, but we don't yet know if it is insignificant.

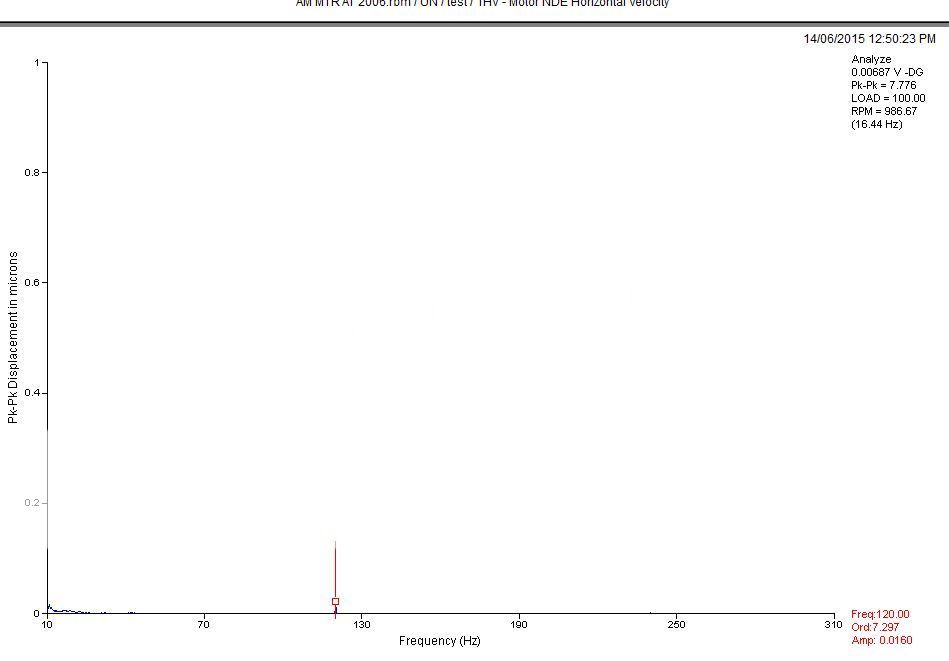

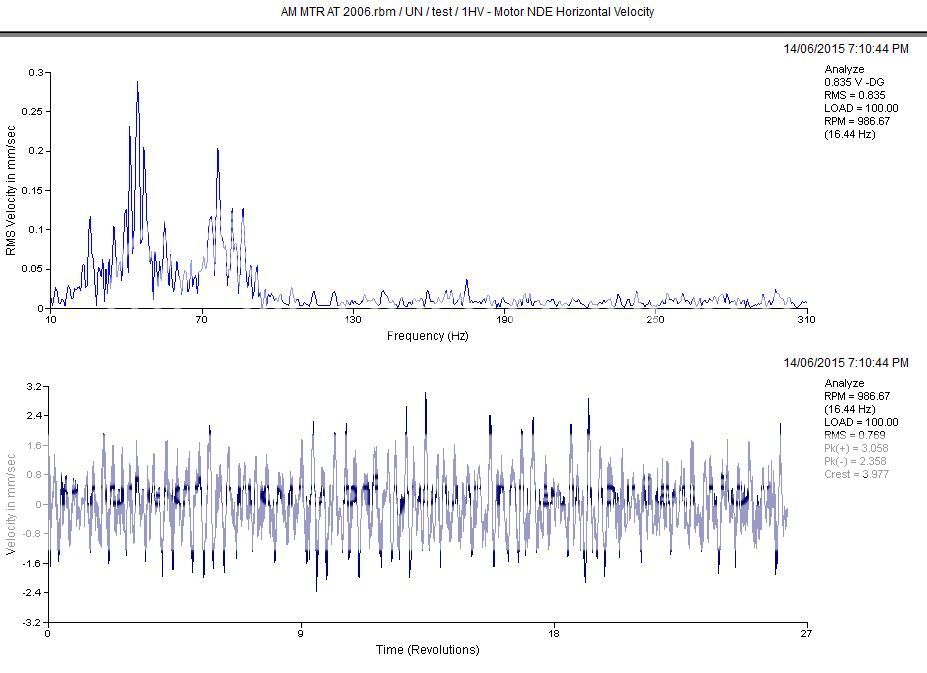

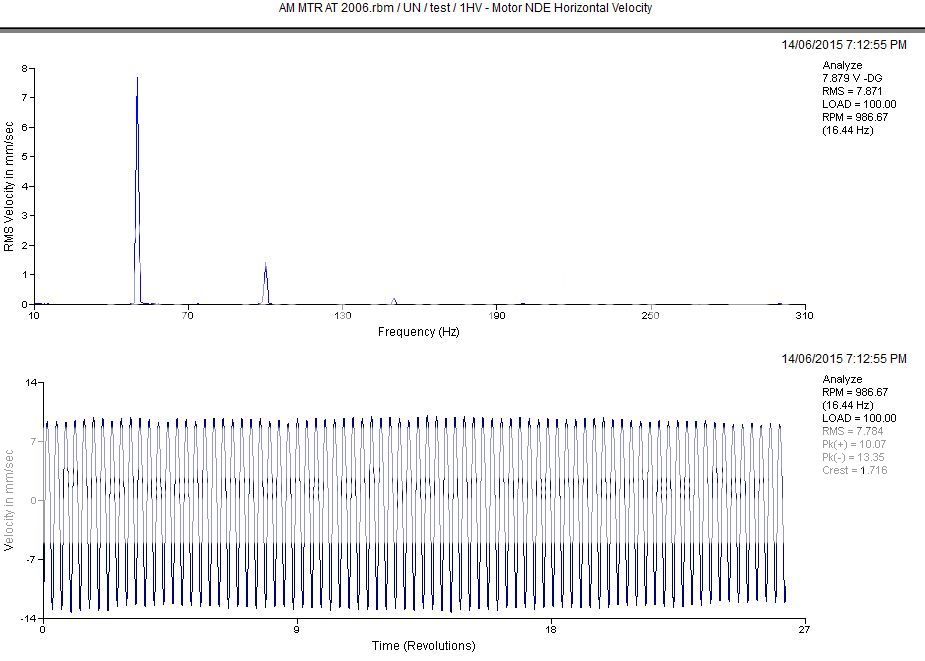

There is logic to your statements here of course, but as I mentioned you need to understand how small this vibration is.

As I mentioned further up the thread I have used very sensitive amplification systems in jet engine test cells where the acoustic pressure levels were over 120 dB without problem. Another poster was talking about the qualification testing he has to do on military audio equipment vibrating kit with shakers without any problems becoming apparent.

So am I expecting to see anything in the amp noise floor? Nope.