OK I give in. How do I post a picture. If i go to my pictures and right click on one then click copy then come to this page and click paste nothing shows up. I am sure this has been explained countless times but I tried doing a search and the results were zero not even a hint,it makes me feel like my computer is broken but it is most likely to be me that is broken. Life was so much easier back in the days when cars had carburetors and telephones were Black and had rotary dials.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

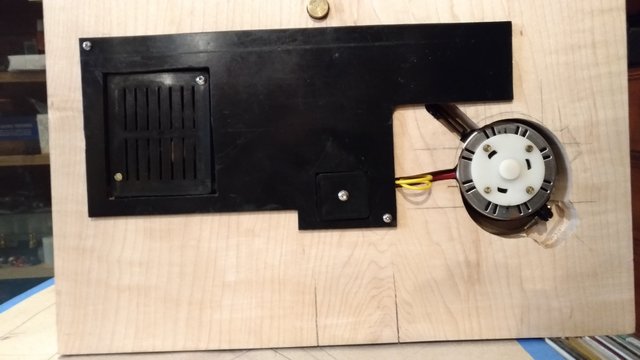

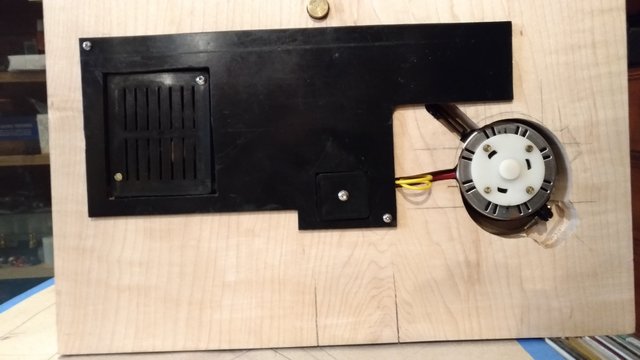

Connoisseur BD1 kit project circa 1973

- Thread starter acass

- Start date

I emailed this picture to myself and it works from there so I'll go to my email for the other 6 pictures.

It's just raw wood at the moment as this is a test run, I'll strip it all down and give it a few coats of Tung Oil and then rebuild it and correct a couple of minor mistakes.

Pictures coming up, I had then all set up but when I hit post reply they vanished, my log in had expired.

The White block is a 3 amp 240 v fuse block.

Some pretty bad router work, I didn't have the work piece clamped securely so the router wandered.

Well that covered my sins nicely.

The 2 dark lines you can see at the end of the board are cracks not pencil lines. They do not go all the way through so I'm not worried, it proves it's real wood.

The problem I do have is a low hum when the stylus is touching the record, I've got to figure that out. It must be the motor but how to stop it????

Alan.

The White block is a 3 amp 240 v fuse block.

Some pretty bad router work, I didn't have the work piece clamped securely so the router wandered.

Well that covered my sins nicely.

The 2 dark lines you can see at the end of the board are cracks not pencil lines. They do not go all the way through so I'm not worried, it proves it's real wood.

The problem I do have is a low hum when the stylus is touching the record, I've got to figure that out. It must be the motor but how to stop it????

Alan.

Craig B

Re:trophile

Have you determined whether this is electrical hum induction vs. mechanical noise breakthrough?The problem I do have is a low hum when the stylus is touching the record, I've got to figure that out. It must be the motor but how to stop it????

Electrical hum is likely to be present even without the stylus touching the record, and often increases in level as the arm is moved closer to the running motor. If electrical, then a broad grounded metal plate through which the motor spindle/pulley protrudes should suffice. I do believe there was one such metal plate included within the BD1 kit (sorry, I couldn't resist). On that note, the electrics running from back to front to switch and back again may well be creating a field that needs shielding from above.

If it proves to be mechanical noise breakthrough then it may be down to the motor mounting not providing enough isolation. As you are using the motor tension band, I assume the standard motor mount is in place. Is this the 3 x small O-ring affair, or the later 3-armed rubber yoke type?

Last edited:

The motor mount is the 3-armed yoke. I'll order a new belt and while I'm waiting for it I will remove everything from the Maple block and set it up on the prototype Bamboo chopping block and see how that sounds. I never did try it with the arm on. I will also widen the pocket that the motor sits in on the Maple block and enlarge by a little the hole for the drive pulley.

Craig B

Re:trophile

If it proves to be mechanical noise breakthrough, it could be as simple as the motor shorting against the cutout in the wooden plinth, and/or the motor tension band being too tight.

Are you sure that a line that connects the two motor mounting holes is the same distance from the centre of the platter bearing hole as on the original motor board?

Are you sure that a line that connects the two motor mounting holes is the same distance from the centre of the platter bearing hole as on the original motor board?

Last edited:

You'll have to come round with your copy as my Grandma borrowed mine.

The Bamboo board works fine. I think you were right the motor must have been barely touching the Maple or else it was osmosis.

I did notice the lower notes are a bit muddy/ boomy??? The First Album I played sounded great it was a 180 g copy of Eva Cassidy Song Bird but when I put on Santana's Abraxas it would not track it just played a note here and there. I raised the height of the platter and it played OK except for the lower notes, as mentioned earlier. When I was setting up the SME arm it did say that it should be parallel to the record surface but I had my doubts about that as it looks like the back of the Shure V15 III is touching the record surface. Also I am very limited with the height of the on/off switch and the motor pulley,the SME arm is as low as it will go unless I router out a pocket for it on the plinth;s surface. That would lower it by 3/8" but it would not be pretty, I'm not expecting to get "Concours de Honor" just hoping for it to not look too bad.

The Bamboo board works fine. I think you were right the motor must have been barely touching the Maple or else it was osmosis.

I did notice the lower notes are a bit muddy/ boomy??? The First Album I played sounded great it was a 180 g copy of Eva Cassidy Song Bird but when I put on Santana's Abraxas it would not track it just played a note here and there. I raised the height of the platter and it played OK except for the lower notes, as mentioned earlier. When I was setting up the SME arm it did say that it should be parallel to the record surface but I had my doubts about that as it looks like the back of the Shure V15 III is touching the record surface. Also I am very limited with the height of the on/off switch and the motor pulley,the SME arm is as low as it will go unless I router out a pocket for it on the plinth;s surface. That would lower it by 3/8" but it would not be pretty, I'm not expecting to get "Concours de Honor" just hoping for it to not look too bad.

Craig B

Re:trophile

What is meant by this is that the tonearm height should be set such that the arm tube is parallel to the record during play. Should this be the case, then no Shure cartridge body should come near to touching the record at the back end.When I was setting up the SME arm it did say that it should be parallel to the record surface but I had my doubts about that as it looks like the back of the Shure V15 III is touching the record surface.

From your description, it seems as though you can't really get the wood thin enough such that the motor pulley is high enough above the top surface of the plinth, necessitating playing about with platter bearing height and difficult tonearm adjustments. Should this be the case, then despite your best efforts it might just be a lot less hassle to go with the metal motor board/chassis that came with. Your maple board is part way there already, simply cut through completely in a 'D' shape that accommodates the switch box through motor and platter bearing, and then drill the four chassis mounting pilot holes.

You likely wouldn't be far off from this lovely thing in the end...

Last edited:

mark.king

pfm Member

I built one of these for my college project back in 1978. I got a AT1009 12 inch arm quite cheap and a VMS20 cartridge. It sounded good but I didn’t like the small plater. It was left at my dads for about 20 years after I got married. When I picked it up after my dad passed away anything rubber had totally perished. The only thing I recovered from it was the arm.

Craig B

Re:trophile

Yeah, a 12" tonearm would make the 10" platter look even smaller.I built one of these for my college project back in 1978. I got a AT1009 12 inch arm quite cheap and a VMS20 cartridge. It sounded good but I didn’t like the small plater. It was left at my dads for about 20 years after I got married. When I picked it up after my dad passed away anything rubber had totally perished. The only thing I recovered from it was the arm.

Not as bad as it might have looked if it could have been fit to an RCA Victor 45J, mind.