I’ve just been messing about with my Townshend 3d Seismic Sink which was pretty effective under my Rega back in the day. Mostly used under electronics these days. Might be worth looking at isolation.

Something like these maybe.

stackaudio.co.uk

stackaudio.co.uk

Something like these maybe.

HighFidelity Magazine review the AUVA EQs - Stack Audio

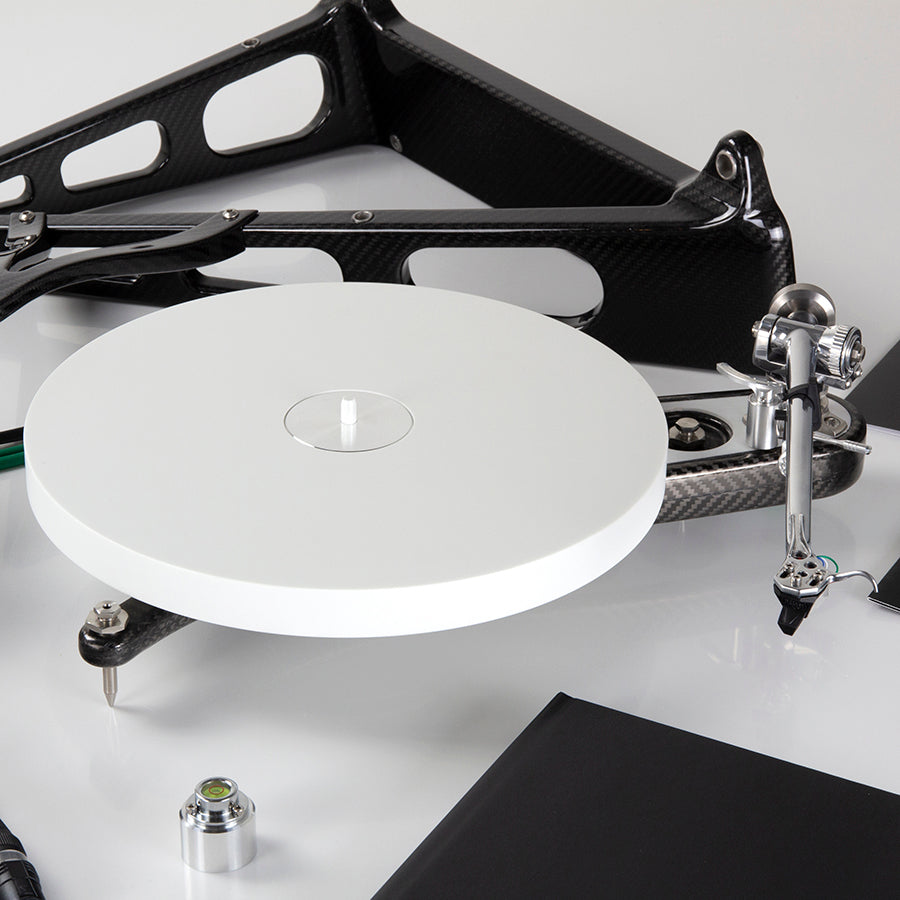

Highfidelity Magazine recently reviewed our AUVA EQs, experimenting with them under several pieces of Hi-Fi & the beautiful Rega Planar 3 50th Anniversary turntable.

stackaudio.co.uk

stackaudio.co.uk