Robert,

I think you could also ask the same question of 1960's British Motorcycle Companies - Ha! Ha!

However, as one who witnessed my friends 'servicing' their 'pride & joy's' back in the 50's & 60's, and in the process using a hammer and screwdriver to remove nuts which they didn't have the correct spanner for, or in some cases when they didn't possess a 'spanner' of any description. Some leaks were the result of, shall we say the use of inappropriate tools / force by previous owners. In some cases of course, where large pressed steel casings had been used by the manufacturers, they were difficult to seal with the materials available at the time.

With respect to my own TD 124, it has never leaked, even after I had removed and re-fitted the bearing cap shortly after I purchased it second hand in the mid 70's. It was then subjected to one or two 'moves' within the U.K., before being transported to and across Canada in the early 80's, and later to Holland via the U.K. in the early 90's - it still hadn't leaked.

As with most things, including my '93 BMW R100 GS, and Landrover Discovery, manufacturers tend to fit parts which they deem 'fit for purpose', but in some instances those parts may be replaced with 'better' quality ones where necessary, or in my case, when I think it will be an 'improvement', which some times turns out to be merely visual - Ha! Ha!

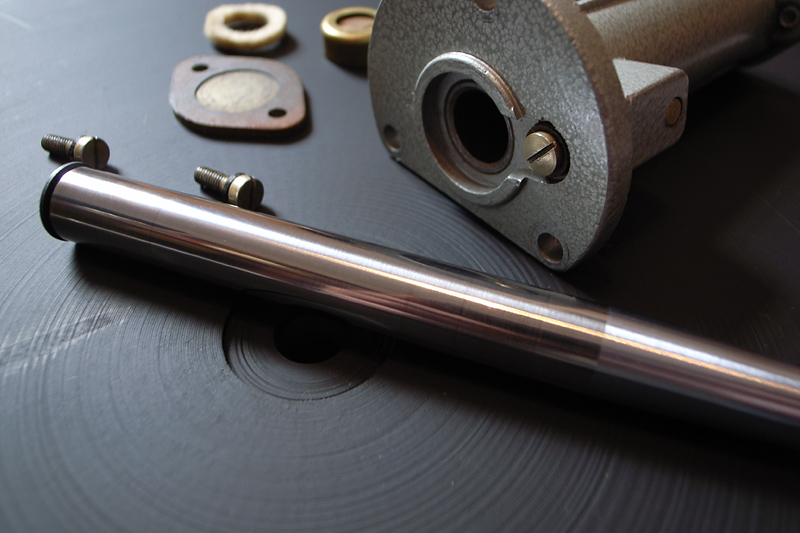

Hence my question to Tony L & 'Shuggie' regarding the substitution of a different bearing end cap for the 'pressed steel' one originally fitted.

Regards

Mike Kelshaw

I think you could also ask the same question of 1960's British Motorcycle Companies - Ha! Ha!

However, as one who witnessed my friends 'servicing' their 'pride & joy's' back in the 50's & 60's, and in the process using a hammer and screwdriver to remove nuts which they didn't have the correct spanner for, or in some cases when they didn't possess a 'spanner' of any description. Some leaks were the result of, shall we say the use of inappropriate tools / force by previous owners. In some cases of course, where large pressed steel casings had been used by the manufacturers, they were difficult to seal with the materials available at the time.

With respect to my own TD 124, it has never leaked, even after I had removed and re-fitted the bearing cap shortly after I purchased it second hand in the mid 70's. It was then subjected to one or two 'moves' within the U.K., before being transported to and across Canada in the early 80's, and later to Holland via the U.K. in the early 90's - it still hadn't leaked.

As with most things, including my '93 BMW R100 GS, and Landrover Discovery, manufacturers tend to fit parts which they deem 'fit for purpose', but in some instances those parts may be replaced with 'better' quality ones where necessary, or in my case, when I think it will be an 'improvement', which some times turns out to be merely visual - Ha! Ha!

Hence my question to Tony L & 'Shuggie' regarding the substitution of a different bearing end cap for the 'pressed steel' one originally fitted.

Regards

Mike Kelshaw

Forgive me if this is a silly question, but why did Thorens design a bearing with an oil leak?