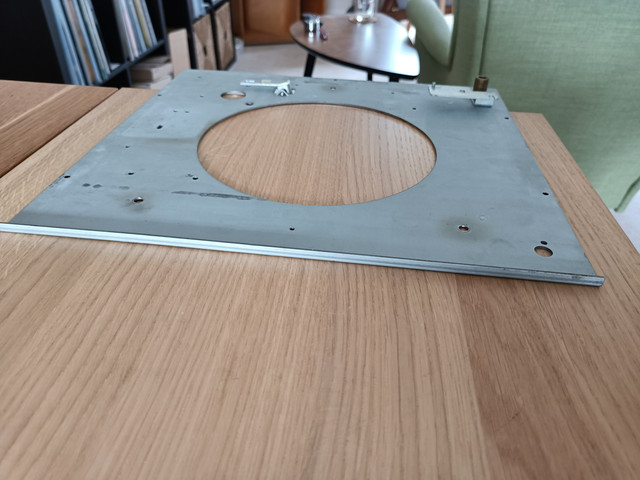

I've acquired a TD150 in a bit of a sorry state, no arm but an SME cut board. I have a spare Hadcock that can go on it but first things first it needs stripping to see what is ok to reuse. On quick inspection the bearing looks ok.

The chassis looks a bit bent and twisted because the drive pulley is touching the speed change/belt guide arm, it also looks like the motor shaft is out of true, so it may end up not being worth restoring, but we shall see.

The chassis looks a bit bent and twisted because the drive pulley is touching the speed change/belt guide arm, it also looks like the motor shaft is out of true, so it may end up not being worth restoring, but we shall see.