Strobes typically turn on when a platter is started. If nothing, then it may be the bulb, and/or a resistor that has failed. The manual has the strobe circuit schematic printed on. Regardless, adjusting the pitch control slider should still alter the speed whether you can easily observe the strobe or no. (i.e. the strobe circuit isn't part of the speed control circuit). The window over the bulb appears to have been disturbed which suggest that this may have failed some time ago. Have you a multi-meter which which to test the bulb and bulb circuit?

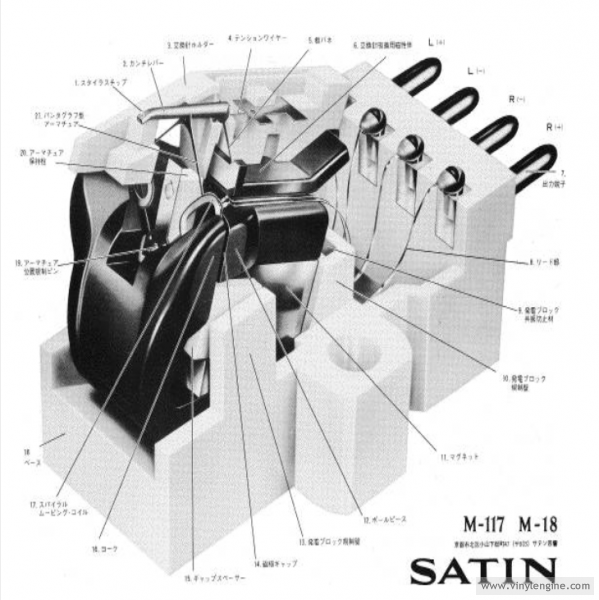

I'd give the old Satin a listen to first. If it does work it may only be in need of a new stylus. Listen out for equal channel balance and a reasonable good sound (could sound a bit rough and sibilant should the tip be worn out). I see that yours is 117Z which has a spherical tip. DaCapo Audio list NOS Satin styli from Japan at €65.60. These more or less have an indefinite shelf life as they don't employ rubber dampers which can perish whether used or not. Then again, a nice audio-technica is a sure bet, and you could sell the Satin on easily should it have problems. BTW, this is a high output MC (aka HOMC) of 2.5mV output that is intended to work into a standard MM phono input.

The tonearm headshell is a friction fit (i.e. no locking collar or specific screws) and pulls straight off from the arm tube, however, the manual warns that one must hold the arm tube firmly so as not to damage the arm bearings. Suggest being extra careful here, or simply mount a new cartridge in-situ without removing the headshell, as, after all these years, it may be difficult to remove (and replacement parts will be unobtanium). The cartridge mounting screws are standard Japanese issue slotted types, only the screws are pointing upwards with the round nuts fitted up top. A small flat-blade screw driver will have these off in seconds. The things to be extra carefull with are the headshell wires as you'll notice that green also connects to headshell metal. This indicates that the internal ground scheme is via Rch-ve, which is then split out to its own dedicated earth wire out back (unless this is fitted with a DIN lead which incorporates earth connection as part of the single plug).

EDIT: The manual also suggests the following:

"A small amount of oil should occasionally be applied the the pad of the top motor bearing."

Presumably, this pad is of felt and accessible beneath the drive pulley at or round the base of the motor spindle where it emerges from the motor housing. I'd use a light oil here, something like Singer sewing machine oil, perhaps applied via hanging a drop off the end of a toothpick or similar. At least enough drops to get this pad damp with oil.