Tony L

Administrator

Some more pics while I give my back another rest:

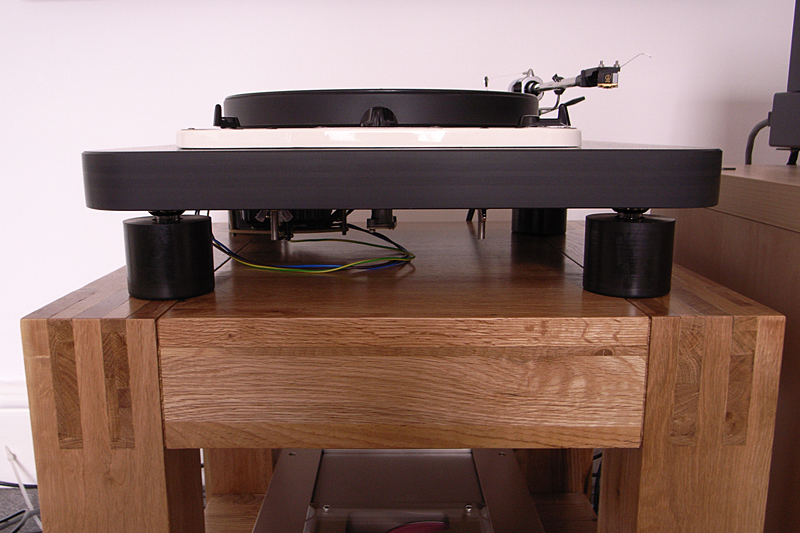

I much prefer this position for the arm to where I had it before with the headshell hanging over the speed knob. It feels more like the Spacedeck to cue now.

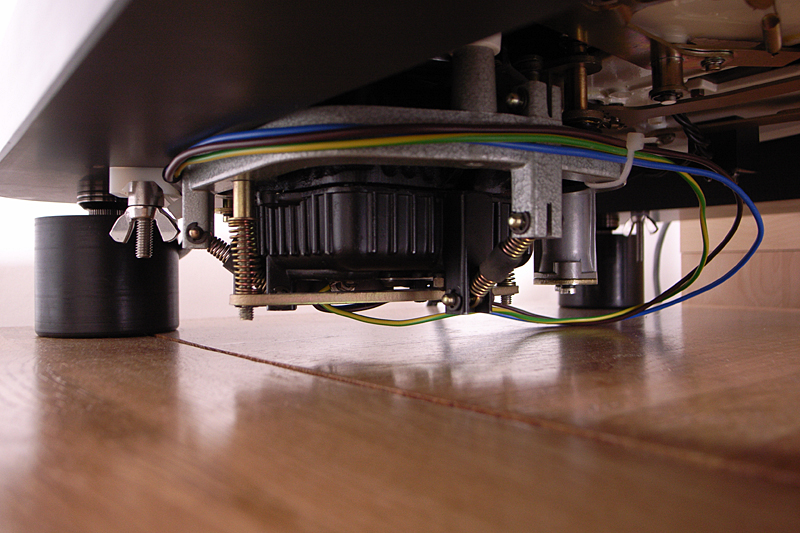

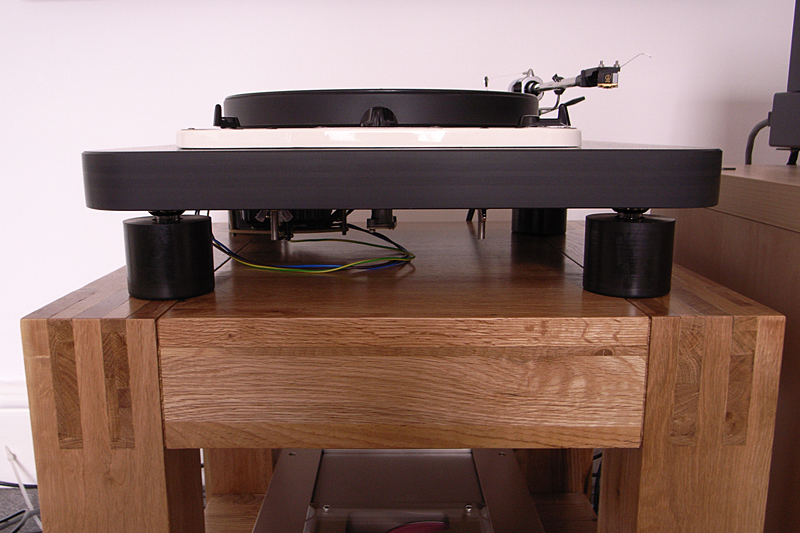

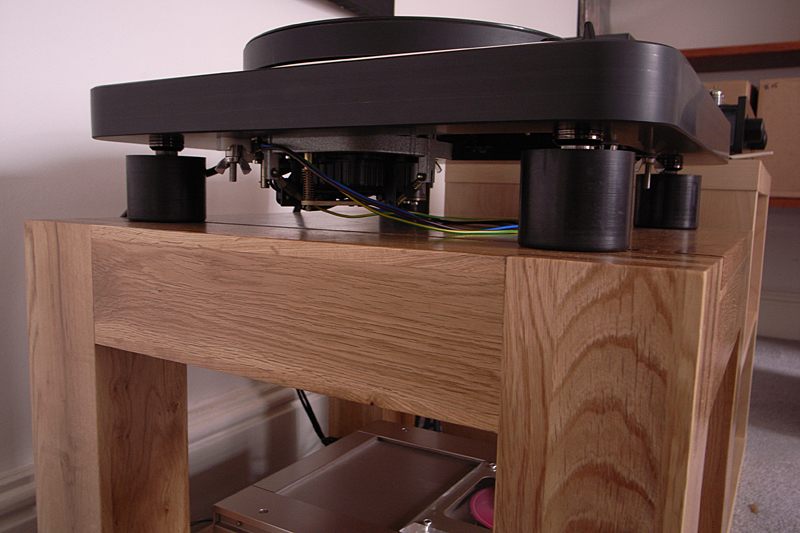

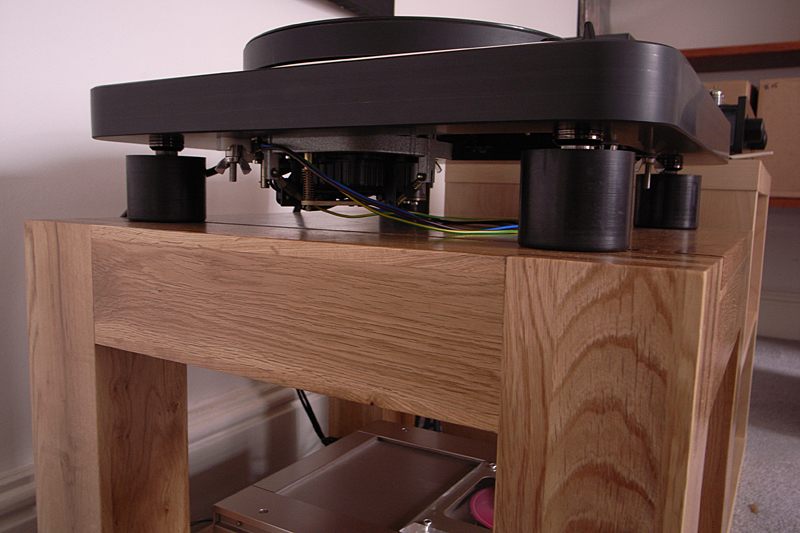

A less flattering view! I'm still not a fan of the decks giblets being on display, but it's 'form dictated by function' rather than window dressing so I'll get used to it. I'll try and think of a neater way to decouple the power wire at some point - I'm running it so long to ensure no motor vibration gets back to the deck up the cable (made a big difference in the last plinth).

Another less flattering view, but it shows how I've got the feet at present (skateboard wheels and little adjustable cones at the top so I can level it). I'm happy with this for the time being. It also shows how I've done the motor wiring, the power is cable-tied firmly to a bracket thingy I've fitted to the back mounting bolt. All nice and secure if not especially pretty. I used wing-nuts as it is so much easier to adjust them with everything in place.

Tony.

PS colour still way out, the cream obviously freaks my Ricoh GR Digital camera out completely.

I much prefer this position for the arm to where I had it before with the headshell hanging over the speed knob. It feels more like the Spacedeck to cue now.

A less flattering view! I'm still not a fan of the decks giblets being on display, but it's 'form dictated by function' rather than window dressing so I'll get used to it. I'll try and think of a neater way to decouple the power wire at some point - I'm running it so long to ensure no motor vibration gets back to the deck up the cable (made a big difference in the last plinth).

Another less flattering view, but it shows how I've got the feet at present (skateboard wheels and little adjustable cones at the top so I can level it). I'm happy with this for the time being. It also shows how I've done the motor wiring, the power is cable-tied firmly to a bracket thingy I've fitted to the back mounting bolt. All nice and secure if not especially pretty. I used wing-nuts as it is so much easier to adjust them with everything in place.

Tony.

PS colour still way out, the cream obviously freaks my Ricoh GR Digital camera out completely.