You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ariston RD11 Capacitors

- Thread starter Mr Pig

- Start date

a.palfreyman

pfm Member

This any use @Mr Pig:

https://www.kenwoodchefrepair.co.uk/store1/Ariston-RD80-RD110-Repair-Kit-p145758649

Edit: unceremoniously nicked from Vinyl Engine:

In the library on this site is a manual that covers the RD11, the RD80 and the RD11 Superieur.

They all use the same circuit. They all have a .22 uf cap for 240v @ 50hz. They all refer to removing the 10k resistor and replacing the .22 uf cap with a .18 uf cap for 110v @ 60hz.

Apparently you can also use a Linn Valhalla etc

https://www.kenwoodchefrepair.co.uk/store1/Ariston-RD80-RD110-Repair-Kit-p145758649

Edit: unceremoniously nicked from Vinyl Engine:

In the library on this site is a manual that covers the RD11, the RD80 and the RD11 Superieur.

They all use the same circuit. They all have a .22 uf cap for 240v @ 50hz. They all refer to removing the 10k resistor and replacing the .22 uf cap with a .18 uf cap for 110v @ 60hz.

Apparently you can also use a Linn Valhalla etc

martin clark

pinko bodger

.. & use X2-rated, pref polypropylene, capacitors. Cheap, guaranteed reliable/ fully rated for use across UK AC mains

not expensive, here;s a really cheap example:

https://www.rapidonline.com/Catalogue/Search?query=0.22uF X2

(Vishay equivs are pennies more; not that it will matter imo.)

not expensive, here;s a really cheap example:

https://www.rapidonline.com/Catalogue/Search?query=0.22uF X2

(Vishay equivs are pennies more; not that it will matter imo.)

This any use @Mr Pig:

https://www.kenwoodchefrepair.co.uk/store1/Ariston-RD80-RD110-Repair-Kit-p145758649

Edit: unceremoniously nicked from Vinyl Engine:

I saw that, the kit is sold on eBay, but it only lists the RD80 and RD110 so I thought the RD11 must be different in some way. It has two caps of different sizes. One could just be stopping switch on thump maybe?

This pic is from an early RD11 - serial 11001456

That's what I've got except the caps are the box style but it's the same thing.

a.palfreyman

pfm Member

According to the Kenwood link, the 10nF goes across the switch, presumably to stop switching noise. The 220nF is the phase cap and the 10k is to drop the input to the motor to 110V

As an aside, I can't quite get my head round the fact that an X2 rated safery cap is designed to fail short circuit in order to blow the fuse in the case of voltage spikes etc. If your appliance has a 13A fuse, that's a lot of joules to dissipate...

As an aside, I can't quite get my head round the fact that an X2 rated safery cap is designed to fail short circuit in order to blow the fuse in the case of voltage spikes etc. If your appliance has a 13A fuse, that's a lot of joules to dissipate...

According to the Kenwood link, the 10nF goes across the switch, presumably to stop switching noise. The 220nF is the phase cap and the 10k is to drop the input to the motor to 110V

So I really should just need to replace the 220nF cap then? I'll have a look in my bits box, I might have one.

martin clark

pinko bodger

Replace the 10k R with a min. 2W metal film resistor at the same time, while it is all apart. No reason not to.

Replace the 10k R with a min. 2W metal film resistor at the same time, while it is all apart.

Why is that?

martin clark

pinko bodger

Because it will cost you 50p, and then the whole job is done forever.

besides which - the orig is likely carbon, and >40yrs old, and while it might measure fine - why not while you are at it?

e.g.:

https://www.rapidonline.com/royal-o...-1-2w-flame-proof-metal-film-resistor-62-8761

besides which - the orig is likely carbon, and >40yrs old, and while it might measure fine - why not while you are at it?

e.g.:

https://www.rapidonline.com/royal-o...-1-2w-flame-proof-metal-film-resistor-62-8761

KC Cheung

Member

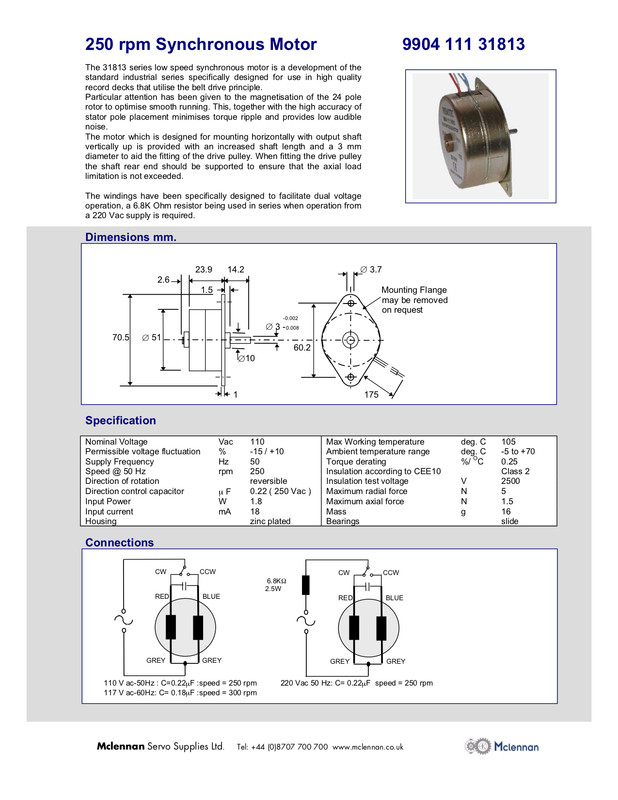

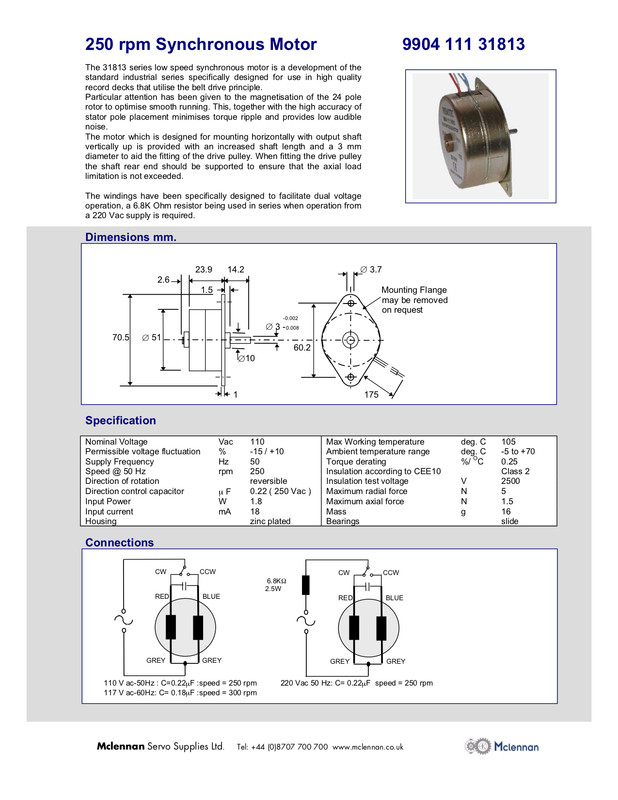

Hi Martin, I just got a RD11s TT last week, I found that the motor and resistor were changed and now are Allied Motion 110V 50Hz motor (9904 111 31813) and 5W 6ohm 8J resistor. Does my resistor is correct to use?Replace the 10k R with a min. 2W metal film resistor at the same time, while it is all apart. No reason not to.

Or I should go back to 10k resistor?

Does my resistor is correct to use?

Does it work? ;0)

I sold one of these a few weeks ago and played it against my LP12, which is forty years younger and higher spec. These old Aristons are not disgraced, they sound very good and are a bargain.

Until people read this post...

KC Cheung

Member

Does it work? ;0)

I sold one of these a few weeks ago and played it against my LP12, which is forty years younger and higher spec. These old Aristons are not disgraced, they sound very good and are a bargain.

Until people read this post...

I got this from ebay 1~2 weeks ago.

It's working but it got a slightly 'Wow' sound from the motor.

My system is on the way to my home from other country, so I can't listen it at this moment.

It's working but it got a slightly 'Wow' sound from the motor.

These motors are not silent. It's normal to get chuffing or scrapping sounds from them but you can't hear it through the speakers. A drop of fine oil on the top and bottom motor bushing is a very good idea, help the motor run more smoothly.

You can use an RPM speed app on your phone to check the speed. Use a roll of tape to the the phone centered on the platter to it doesn't wobble as it rotates.

KC Cheung

Member

These motors are not silent. It's normal to get chuffing or scrapping sounds from them but you can't hear it through the speakers. A drop of fine oil on the top and bottom motor bushing is a very good idea, help the motor run more smoothly.

You can use an RPM speed app on your phone to check the speed. Use a roll of tape to the the phone centered on the platter to it doesn't wobble as it rotates.

Thank you for your advise, will try to lub the motor.

I did the rpm test and it got 33.2x rpm, slightly slower than standard but I think it within the tolerance.

Craig B

Re:trophile

Whomever replaced the motor went with the standard 6k8 (6800 Ohm) as suggested within the motor datasheet. This recommendation is meant to have the motor operate at circa 110V on circa 230V. Most turntable makers run resistor and/or capacitor values that take the mains down to less than 100V. Rega, for example, started out using 15k for both the UK and Europe (same value as in the early RD11/LP12 electrics pic posted by @cre009 in post #4), later changed to 12k UK and 10k Europe; these before going over to using a second 0.22uF X2 rated metal film capacitor as voltage filter in place of the power dropper resistor. Since sometime during the late 90s Rega have taken to combining capacitor and resistor as voltage dropper; with the P3 2000 PCB having 2 x capacitors and 3 x resistors on (as did the circuit included within the original 110V Planar 3 Upgrade Kit).Hi Martin, I just got a RD11s TT last week, I found that the motor and resistor were changed and now are Allied Motion 110V 50Hz motor (9904 111 31813) and 5W 6ohm 8J resistor. Does my resistor is correct to use?

Or I should go back to 10k resistor?

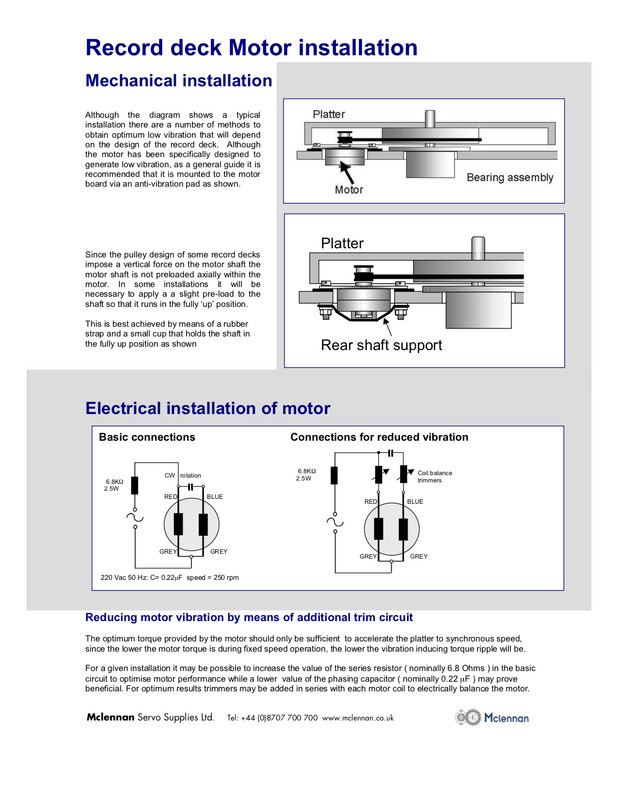

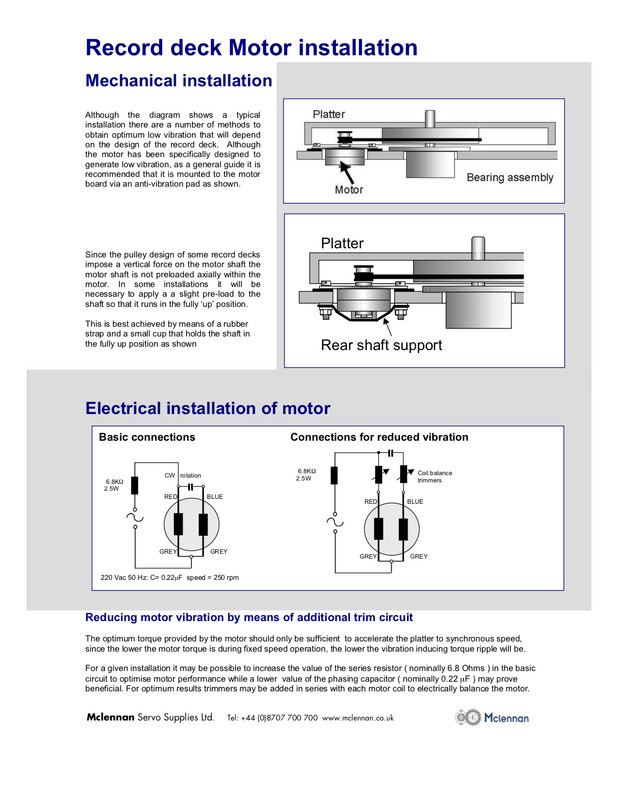

Reduced voltage equates to less motor vibration, that is, as long as the phase capacitor remains capable of doing a reasonable job of approaching a 90º phase shift between the feeds to each motor coil. If Allied Motion had bothered to include the 2nd page of the McLennan datasheet, the person who did this motor/resistor swap out would likely have considered the following...

"The optimum torque provided by the motor should only be sufficient to accelerate the platter to synchronous speed, since the lower the motor torque is during fixed speed operation, the lower the vibration inducing torque ripple will be.

For a given installation it may be possible to increase the value of the series resistor ( nominally 6.8 Ohms ) [Ed: should be kOhms] in the basic circuit to optimise motor performance while a lower value of the phasing capacitor ( nominally 0.22 μF ) may prove beneficial. For optimum results trimmers may be added in series with each motor coil to electrically balance the motor."

For a given installation it may be possible to increase the value of the series resistor ( nominally 6.8 Ohms ) [Ed: should be kOhms] in the basic circuit to optimise motor performance while a lower value of the phasing capacitor ( nominally 0.22 μF ) may prove beneficial. For optimum results trimmers may be added in series with each motor coil to electrically balance the motor."

FYI, with the anniversary Planar 25 Rega fit 0.2uF (via parallel connecting 2 x 0.1uF) as phase cap and fit 2 x 10k pots for hand trimming for lowest vibration (i.e. bare motor actually in hand whilst twiddling these pots). I'm not sure what the voltage drop is before pots with these yet, as they were well into using capacitors as voltage filters. Regardless, as P25 preceded P3 2000, I suspect that the voltages (to each phase) that delivered lowest vibration with P25 were used to determine the fixed capacitors/resistors mix for P3 2000 (and Planar 2/3 Motor Upgrade Kit).

In conclusion, a lot can be learned from looking at these various PCBs/circuits, not to mention that the old 6-way terminal block of RD11/early LP12 makes for a great test platform.

Last edited:

337alant

Negatively Biased

9904 111 31813 Series AC Synchronous Motors by Allied Motion (mclennan.co.uk)

Download the data sheet, agree with the above 0.2uf is the correct Phase shift cap and trimming your mains voltage down with the 6.8K resistor to reduce vibration where your mains is higher than 240VAC can be beneficial to a certain extent but have a listen as I found you start to lose some drive and pace if you go to low

Any additional caps on the original Linn/ Ariston design were only spark suppression across the switch

Alan

Download the data sheet, agree with the above 0.2uf is the correct Phase shift cap and trimming your mains voltage down with the 6.8K resistor to reduce vibration where your mains is higher than 240VAC can be beneficial to a certain extent but have a listen as I found you start to lose some drive and pace if you go to low

Any additional caps on the original Linn/ Ariston design were only spark suppression across the switch

Alan

Craig B

Re:trophile

That 9904-111-31813-ac-synchronous-motors-datasheet.doc wouldn't render properly in Word 365 here, plus the second page that came along with when Mclellan took over has since gone missing.

Here are pages 1 and 2 in .jpeg format. Last two paragraphs on page 2 are what I quoted in post #18 above. Perhaps the second page was simply a separate motor installation document that they decide to include at one point.

Here are pages 1 and 2 in .jpeg format. Last two paragraphs on page 2 are what I quoted in post #18 above. Perhaps the second page was simply a separate motor installation document that they decide to include at one point.