Mike P

Trade: Pickwell Audio

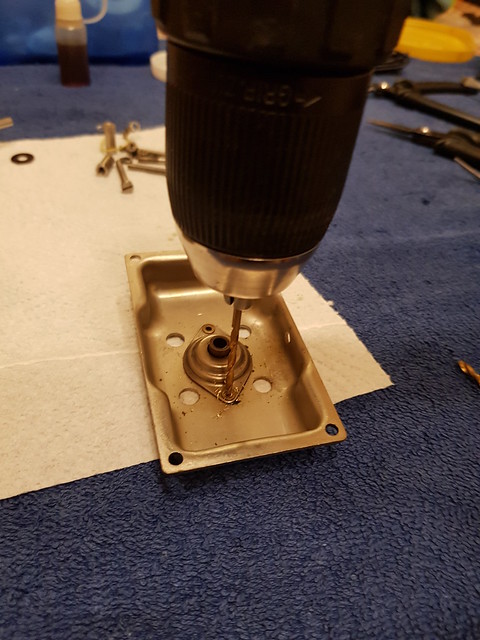

It doesn't show up well on this photo but the motor pulley running surface was quite scratched/marked. Getting this surface nice and smooth is critical to quiet running and so the pulley was mounted in a pillar drill and the marks sanded out with fine abrasive paper. The pulley was then polished up with metal polish in the same way.

20240318_201758 by Michael Pickwell, on Flickr

20240318_201758 by Michael Pickwell, on Flickr

The stepped pulley was also polished.

20240318_201758 by Michael Pickwell, on Flickr

20240318_201758 by Michael Pickwell, on FlickrThe stepped pulley was also polished.