You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upgrading Yamaha NS-1000Ms

- Thread starter James

- Start date

Pete MB&D

Pete Maddex, the one and only!

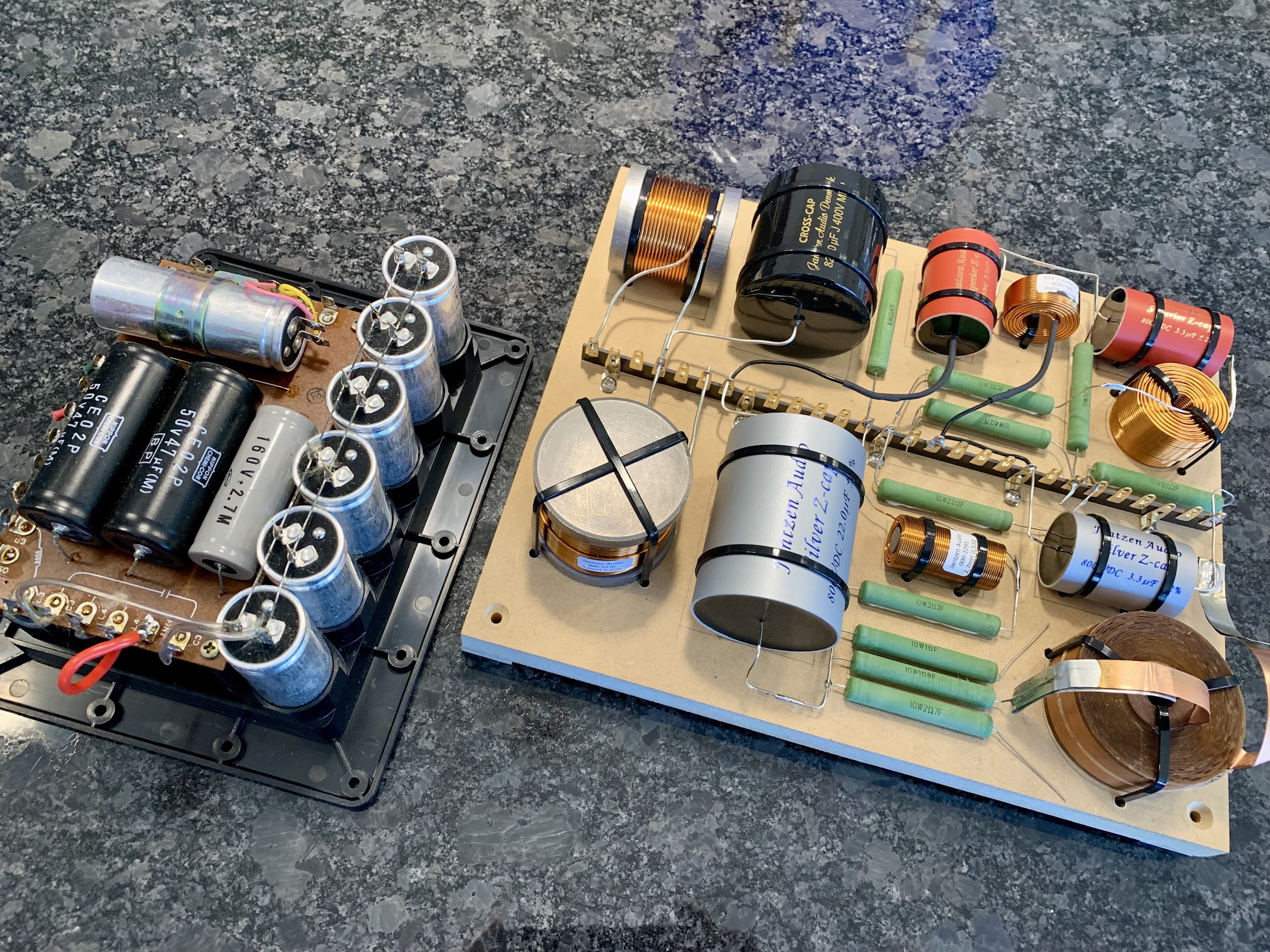

Progress has been a bit slow. But the crossovers have now been built. The last weekend was spent fashioning the new back plates and pulling out the drivers and existing wiring.

Should be ready to wire up the new crossovers next weekend. The new crossover takes up a bit more real estate, but will fit on the rear panel with four screws.

I would like to see the wires wraped around the tag strips for a more secure connection, just relying on solder in a high vibration enviroment is asking for dry joints.

And the inline connections should have hooks on the ends and then crimped tight and soldered.

I used to replace a lot of big mains dropper resistors in TVs and made sure they would remain connected after lots of heat cycles.

Pete

James

Lord of the Erg\o/s

That's a fair point, Pete, and I can understand heat/cooling cycles could cause dry joints. However, I imagine that it'd take much more vibration than a loudspeaker cabinet might suffer to work a joint loose. When I hook up the wires for the drivers, I'll rewet the joints and bend the legs so there's a mechanical hold.

Pete MB&D

Pete Maddex, the one and only!

I would like to see the wires wraped around the tag strips for a more secure connection, just relying on solder in a high vibration enviroment is asking for dry joints.

And the inline connections should have hooks on the ends and then crimped tight and soldered.

I used to replace a lot of big mains dropper resistors in TVs and made sure they would remain connected after lots of heat cycles.

Pete

I think you overestamate the strength of solder, try benging a length backwards and forwards and see how quickly it breaks.

Pete

I think you overestamate the strength of solder, try benging a length backwards and forwards and see how quickly it breaks.

Pete

For a good solder join between wires and tags, you need a good surface area with a nice basic fillet join of solder from the wire to the tag. Wrapping the wire will just give you a much larger surface area and stronger join.

I personally like turrets, if you wrap the wire 180-270Deg round the turret and solder it in place you have a super strong attachment.

Zombie

pfm Member

Finnish broadcasting company made active ones. Owned a pair once.Have you ever considered running these babies in an active configuration…?

Bill Colledge

pfm Member

James,

Do you intend incorporating the Yamaha tone controls on the Mid and tweeter.

Bill

Do you intend incorporating the Yamaha tone controls on the Mid and tweeter.

Bill

James

Lord of the Erg\o/s

Not really. I'd need a custom-designed set of active filters and a couple more amplifiers. The other reason is I don't like the idea of connecting amplifiers directly to mids and tweets without a capacitor to stop potential DC from destroying them - especially since these beryllium drivers are nearly unobtainable except for salvage units of unknown provenance.Have you ever considered running these babies in an active configuration…?

James

Lord of the Erg\o/s

For a good solder join between wires and tags, you need a good surface area with a nice basic fillet join of solder from the wire to the tag. Wrapping the wire will just give you a much larger surface area and stronger join.

I personally like turrets, if you wrap the wire 180-270Deg round the turret and solder it in place you have a super strong attachment.

I've used turrets in my previous designs. Unfortunately, the ones I have can't be swaged to 18mm thick MDF.

James

Lord of the Erg\o/s

BillJames,

Do you intend incorporating the Yamaha tone controls on the Mid and tweeter.

Bill

Originally I did, but changed my mind based on advice from Troels Gravesen. His redesigned XO have a couple of resistors that can be swapped to tweak the relative levels of the mid and tweet. This is another reason why I have not wrapped some of the component legs around the tags or each other. They'd be a b!tch to unsolder.

James

JimmyB

pfm Member

For a good solder join between wires and tags, you need a good surface area with a nice basic fillet join of solder from the wire to the tag. Wrapping the wire will just give you a much larger surface area and stronger join.

I personally like turrets, if you wrap the wire 180-270Deg round the turret and solder it in place you have a super strong attachment.

Big soldering iron needed for that one!

James

Lord of the Erg\o/s

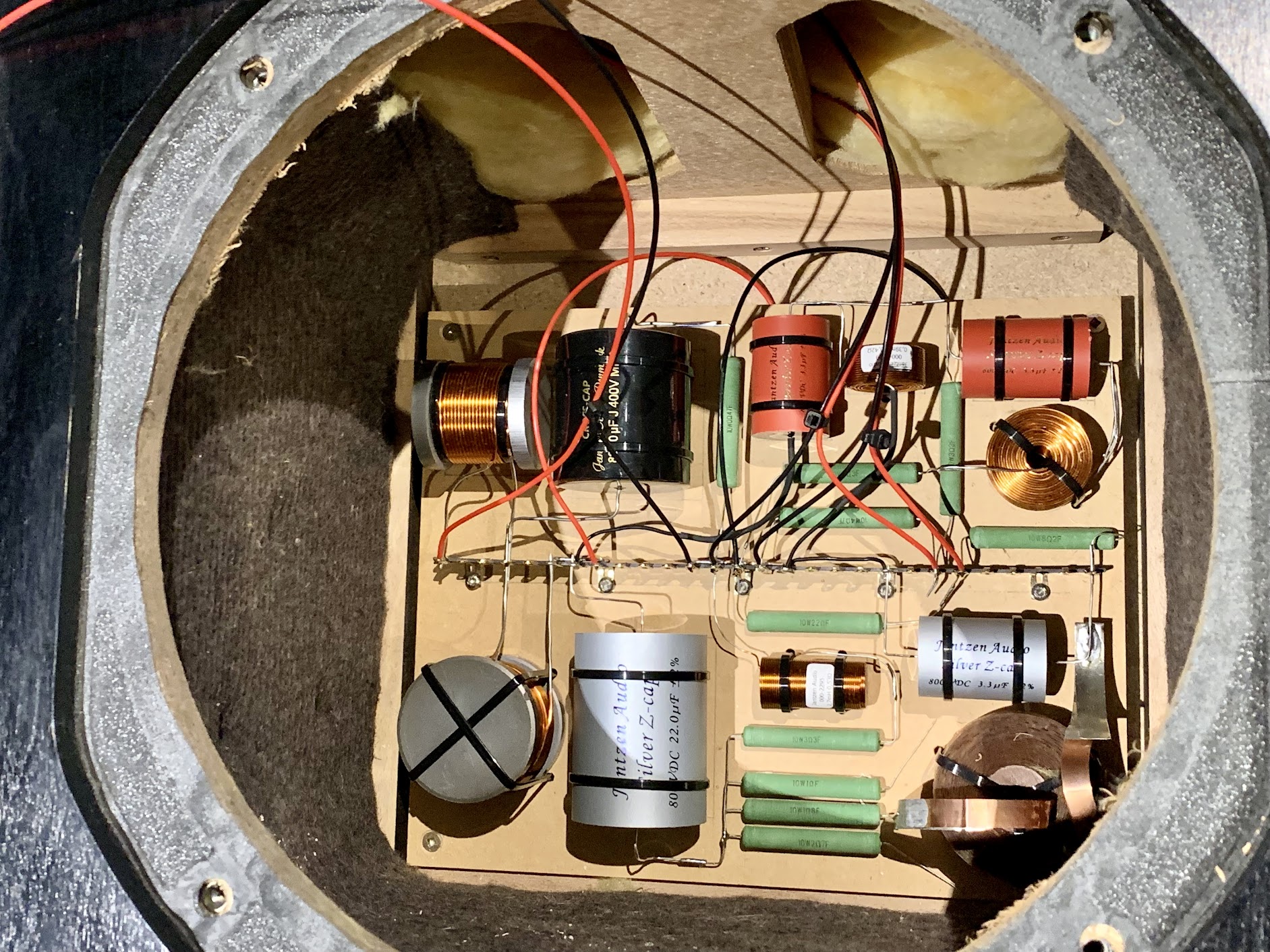

The good news is everything has come together nicely.

The bad news is one of my woofers has its magnet shifted, and now that voice-coil is stuck. Apparently, that is quite a common affliction of the old Yamahas woofers. All it took to shift was a wee drop when I laid it on its back to torque up the bolts. So, it'll have to take some time off for repairs.

I hope the damage is not terminal, and once fixed not too different from the other one.

Sh!t happens, but in the grand scheme of things, this is inconsequential. Just inconvenient.

The bad news is one of my woofers has its magnet shifted, and now that voice-coil is stuck. Apparently, that is quite a common affliction of the old Yamahas woofers. All it took to shift was a wee drop when I laid it on its back to torque up the bolts. So, it'll have to take some time off for repairs.

I hope the damage is not terminal, and once fixed not too different from the other one.

Sh!t happens, but in the grand scheme of things, this is inconsequential. Just inconvenient.

Last edited:

iansr

pfm Member

I’ve never heard an NCC300 but I’d still put money on the 686 being better - Tom’s amps are that good.If he agrees to a visit in March, I'm going to propose that we bring my friend's stereo NCC300 along, to do a head-to-head. Or perhaps he would lend us one for a couple of days so we could test it in my friend's system. I'm quite curious to see how they compare, as can't recall hearing an amp better than the NCC300.

James, sorry for hijacking your thread to talk about amps. I suppose, though, that it's your fault for bringing it up.

Mike Hanson

Trying to understand...

I was able to meet with him during my visit last week to Calgary, although there was no opportunity to do a shoot out. He's a wonderful fellow, and I'll be continuing with my build this weekend.I’ve never heard an NCC300 but I’d still put money on the 686 being better - Tom’s amps are that good.

rontoolsie

pfm Member

The Yammy xo were an order of magnitude superior in parts quality to the contemporary competitors.. Isobarik DMS, KEF 105 etc al. At a time where parts quality in xo were considered much less important than they are now, Yamaha was almost visionary.

James

Lord of the Erg\o/s

Thanks to my mate @RustyB, the wayward woofer is now back to full health. As a precaution for the other one, which I think could let go with a jolt, I've applied a bead of epoxy resin around the top and bottom junction of the ferrite ring. If the original adhesive should fail, at least I hope the epoxy will keep it aligned. They have been playing music now for two days, and here are my impressions:

First, the tonal balance is better balanced with a nicely weighted bottom end. I know it's hard to imagine how an XO change could effect that, but it does. I suspect the relativity of MF and HF levels have been corrected. I can now pull the NS-1000Ms slightly further into the room, where it produces superbly articulate and tuneful bass. It won't go much lower than 40Hz, but that's plenty of reach for mid-bass punch that you can feel.

Second, the edginess of the upper mid and slight tendency to exaggerate sibilance is completely gone. Whether it is due to better caps or more accurate crossover filters I can't tell. But it is a revelation to have hear-through transparency without the uncomfortable edge that I sometimes anticipate, and try to ameliorate with my class-A amp. They sound even better now with class-AB Densen amps. I have yet to try it with my class-A just now.

Third, voices and acoustic instruments sound more organic with better body and definition. It also seems easier to differentiate ppp from fff levels that coexist in a mix. There's a palpability that produces an immersive listening experience. I knew NS-1000Ms are special, but I have never heard them sound this good.

Now, I realise there may be some expectation bias. But I know when something sounds right. The Troels Gravesen upgrade makes the venerable Yamahas sound more right than I really expected. If anyone wants to treat their NS-1000Ms to a hell of an upgrade, you won't need to look further. Just remember not to jolt the ancient woofers and dislodge the magnet.

You have been warned.

First, the tonal balance is better balanced with a nicely weighted bottom end. I know it's hard to imagine how an XO change could effect that, but it does. I suspect the relativity of MF and HF levels have been corrected. I can now pull the NS-1000Ms slightly further into the room, where it produces superbly articulate and tuneful bass. It won't go much lower than 40Hz, but that's plenty of reach for mid-bass punch that you can feel.

Second, the edginess of the upper mid and slight tendency to exaggerate sibilance is completely gone. Whether it is due to better caps or more accurate crossover filters I can't tell. But it is a revelation to have hear-through transparency without the uncomfortable edge that I sometimes anticipate, and try to ameliorate with my class-A amp. They sound even better now with class-AB Densen amps. I have yet to try it with my class-A just now.

Third, voices and acoustic instruments sound more organic with better body and definition. It also seems easier to differentiate ppp from fff levels that coexist in a mix. There's a palpability that produces an immersive listening experience. I knew NS-1000Ms are special, but I have never heard them sound this good.

Now, I realise there may be some expectation bias. But I know when something sounds right. The Troels Gravesen upgrade makes the venerable Yamahas sound more right than I really expected. If anyone wants to treat their NS-1000Ms to a hell of an upgrade, you won't need to look further. Just remember not to jolt the ancient woofers and dislodge the magnet.

You have been warned.

PigletsDad

My intelligence test came back negative.

Always been one of my favourites; a visionary design.

James

Lord of the Erg\o/s

They are truly ahead of their time.Always been one of my favourites; a visionary design.

When I was awaiting the return of the repaired woofer, I wondered what I'd do if the repair irreversibly changed the T/S parameters so the pair was no longer matched. I seriously thought about recycling the beryllium mid and tweeter in an Ergo tribute to the NS-1000M - by matching them with a 13" Scan-speak woofer. I've even gone on to tally up the cost of updating my LspCAD licence, buying a cheap laptop PC, and thinking about how I'd route the non-circular cutouts for the Yamaha drivers.

Thank goodness I can park that idea for a while. I'm not sure I can better the updated NS-1000Ms. They sound magnificent.