Tony L

Administrator

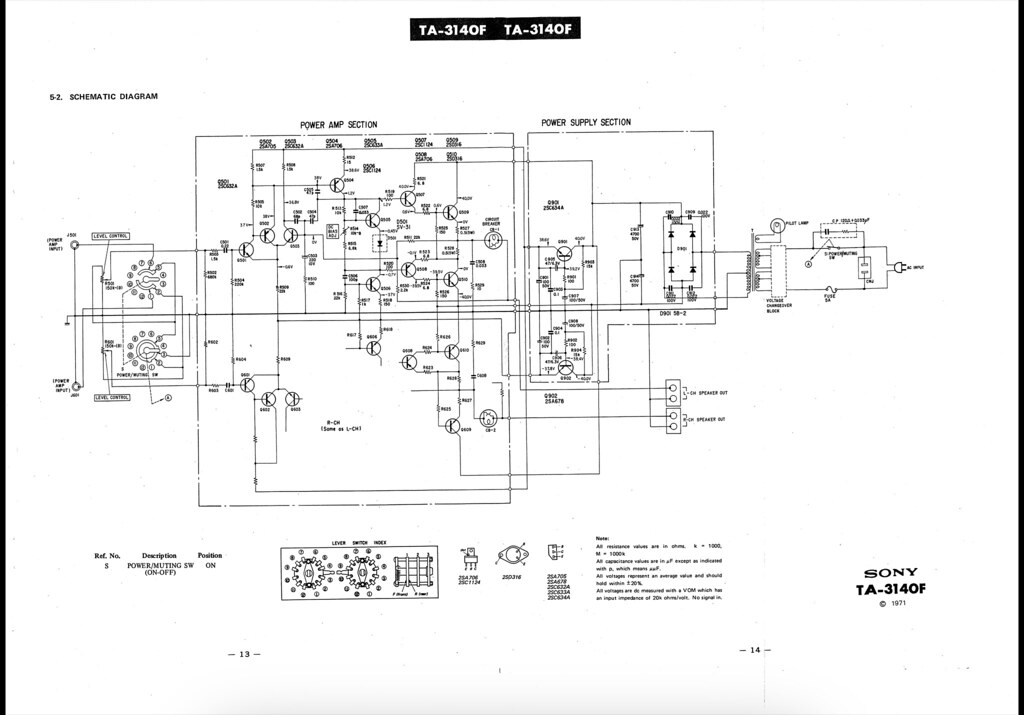

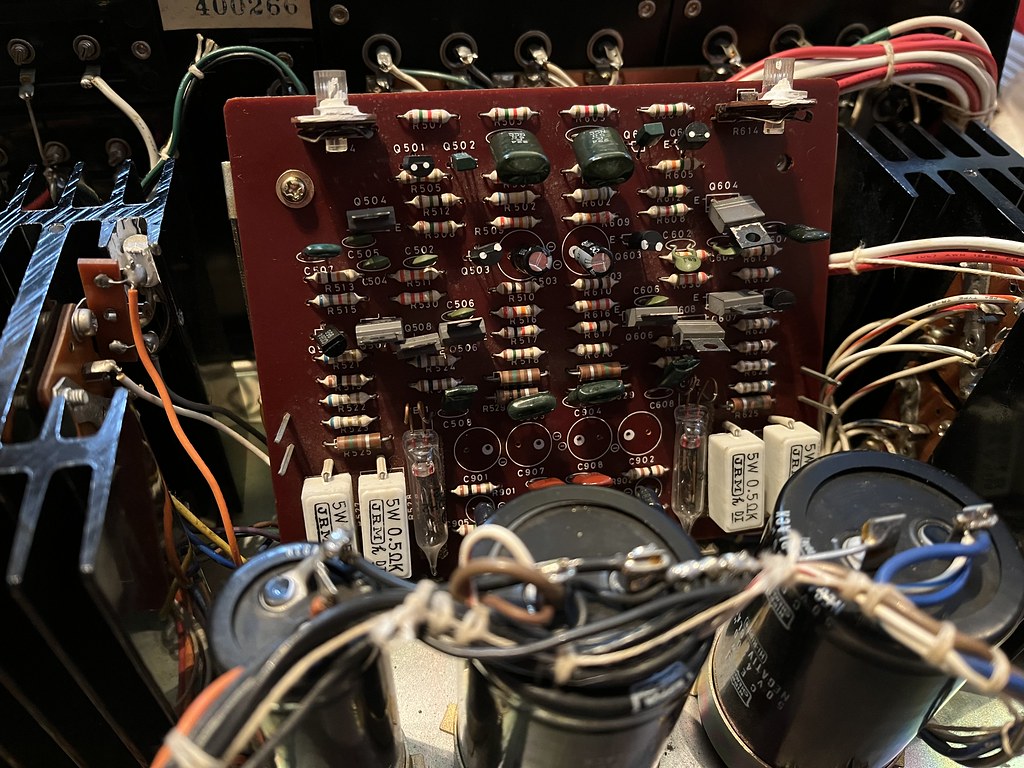

I’m trying to restore a lovely old (1971-74) Sony TA-1140 amp and I’m running into an issue with noisy transistors somewhere. It has a thread in the Classic room, but I don’t think anyone with technical knowledge has read it! The amp works fine, I’ve recapped most of it, but there is intermittent crackling in (I’m pretty certain) the power amp section.

No microphonic issues, tapping the board with a plastic stick reveals no clues. Crackling is on both sides, random, and in stereo, i.e. not PSU which I assume would be mono over both channels. Each channel does its own thing intermittently and it seems to stabilise fully after half an hour or so.

The transistors in the power amp section are as follows:

2SC632A

2SC633A

2SC634A

2SC1124

2SA705

2SA706

Annoyingly they seem obsolete and I’m miles out of my knowledge area here. I’d happily do them all if I could buy them. I don’t understand transistor spec sheets at all. Just totally beyond my education level. I understand enough to grasp that simply finding a “substitute” on a website may not mean it is a genuine drop-in replacement (even allowing for a maybe different pin-out). It appears the 2SC63x types are notoriously noisy so ideally I’d just like to start at the top of the list and do the 2SC632As and work down from that. From what I’ve read they may well be the most likely. Anyone know a drop-in replacement? The service manual is on HiFi Engine.

I’d really appreciate some help here as it is potentially a lovely old amp and is otherwise pretty much mint condition.

No microphonic issues, tapping the board with a plastic stick reveals no clues. Crackling is on both sides, random, and in stereo, i.e. not PSU which I assume would be mono over both channels. Each channel does its own thing intermittently and it seems to stabilise fully after half an hour or so.

The transistors in the power amp section are as follows:

2SC632A

2SC633A

2SC634A

2SC1124

2SA705

2SA706

Annoyingly they seem obsolete and I’m miles out of my knowledge area here. I’d happily do them all if I could buy them. I don’t understand transistor spec sheets at all. Just totally beyond my education level. I understand enough to grasp that simply finding a “substitute” on a website may not mean it is a genuine drop-in replacement (even allowing for a maybe different pin-out). It appears the 2SC63x types are notoriously noisy so ideally I’d just like to start at the top of the list and do the 2SC632As and work down from that. From what I’ve read they may well be the most likely. Anyone know a drop-in replacement? The service manual is on HiFi Engine.

I’d really appreciate some help here as it is potentially a lovely old amp and is otherwise pretty much mint condition.