I've just seen a post on facebook from Chris Harban and know there will be several here who'll be interested to read, so am pasting the full content:

"For the TD124 motor..... sorry, this is not a fun opinion to have, but it is based on careful observations over a long period of time, and with quite a few TD124 motors. I have been avoiding making this post for long time now.

Shown in the photo is a particularly bad example of about 1 year of run time on an aftermarket bushing. I have not yet seen this much wear on a motor spindle with original bushings. In almost all cases, nowhere even close.

My current (strong) recommendation is to avoid replacing the motor bushings with aftermarket bushings. The alloy used in the original bushings is different, the new bushings cause excessive and immediate wear on the motor spindle due to being manufactured from an alloy which is not a good choice for a precision motor bushing. Acceptible results can be had, but longevity is the main issue for me. The difference between the new alloy and the original alloys is very significant in terms of the quality of the wear patterns created by the two different alloys. It is dead obvious if you know what to look for and set up a comparative experiment / example.

There have been various aftermarket options for TD124 motor bushings. Some of them are machined phosphor bronze bushings, and are of an alloy that is more friendly to the motor spindle, but they are not sintered, and thus, a complete non-starter for me. Some people might have what it takes to keep them lubricated, but in the long run, most will not and lubrication will eventually fail.

Because the original bushings are often worn, this presents a serious conundrum for the TD124. It is rare to open up an unmolested TD124 motor and see any real damage or wear on the spindle, even in motors where the lubrication failed long ago and they are all siezed up. Most often they look pretty good. The alloy used in the original bushings is pretty friendly on the specific finish and hardness of the motor spindle.

I have been developing a method of resizing the original bushings of the TD124 motor. This is definitely not DIY and also needing some specialized and not inexpensive equipment. There is a learning curve to it. I saved many of the bushings I have replaced in the past, so I had stock to experiment with and learn. I use precision collets in a turret lathe, set up with a specifically sized Deltronic 'tenth' pin to maintain the concentricity and i.d. dimensions of the bushing bore.

What can be done at home, is thoroughly cleaning the original bushings using heat, compressed air, ultrasonic cleansing in acetone (in a glass jar dipped into an ultrasonic tank. Multiple rounds using each of these methods in succession will clean out the porous structure. At the beginning, using compressed air will reveal that the porous structure is completely clogged. At the end, compressed air will reveal that the porous structure is clear and open again. They can then be recharged with oil, preferably in a vacuum, but in a pinch, in a heated oil bath.

Replace the motor felts and oil with Mobil DTE25.

If your motor case does not have an oiling access hole in the lower motor case half, I recommend learning where and how large the hole is, and drilling it. I do this to motor cases without the hole.

Keep your motors lubricated on a schedule based on frequency of usage. This is easier for me that for some, so your lubrication schedule will probably be different than mine, and results may vary.

If your original motor bushings are marginal in terms of wear, cleaning them as described above, and keeping them lubricated is a start, it will help.

Badly worn bushings can cause motor noise. These need to be re-sized.

While on the subject of motor noise, there are two brass retainers for holding the motor bushings secure. The 4 tabs on these are angled, and act like springs. These really should have been made from spring steel as they are in the Garrard 301 / 401, but, just be sure if you are in there that these are angled upward and not flat. Insufficient spring tension against the motor bushings from these retainers can cause a rattling type of vibration in the E50 motor.

I have not been taking in any TD124 work involving motors for quite a while now due to this observation, and am still not taking any in. I know 100% that what I am observing is correct. I became aware of it while experimenting with different bronze alloys for my Garrard 301 / 401 main bearing.

I now have a process that is giving good results, and will be sharing this method for resizing the original bushings at some point in the near future for people who rebuild these decks. For professional rebuilders, the tooling is not that expensive, but will require care in setting it up, and also some time with learning.

This is just a 'heads up' for TD124 owners and those considering becoming a TD124 owner."

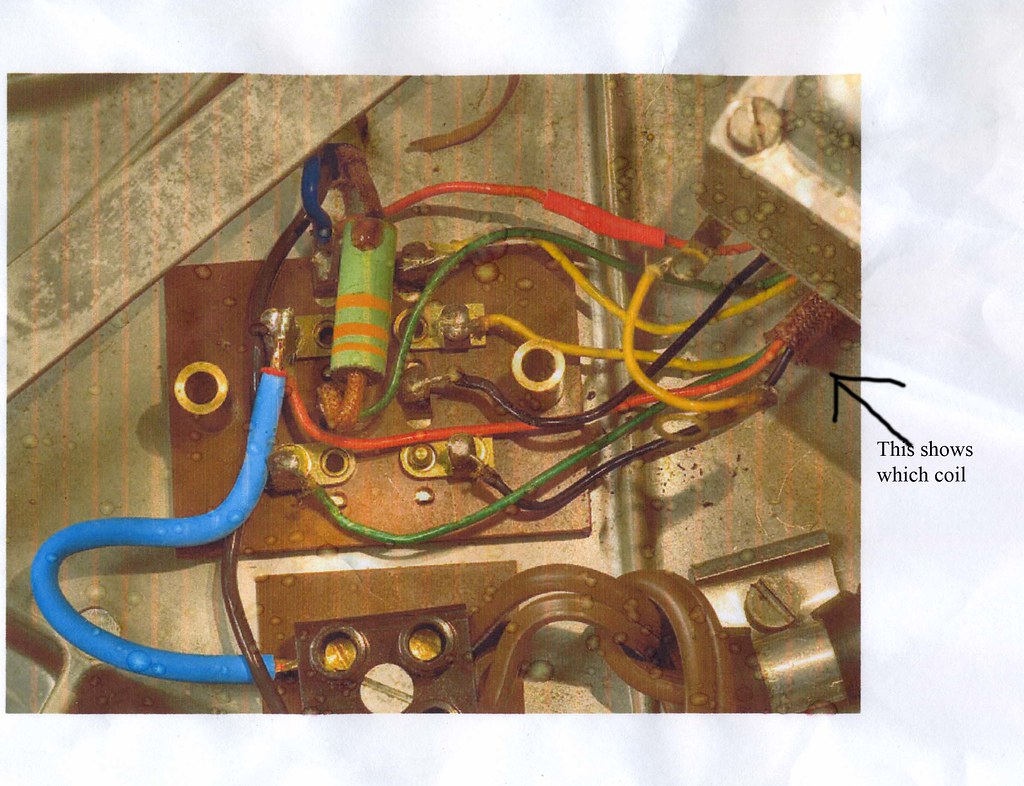

124-Motor wiring by dave_slater, on Flickr

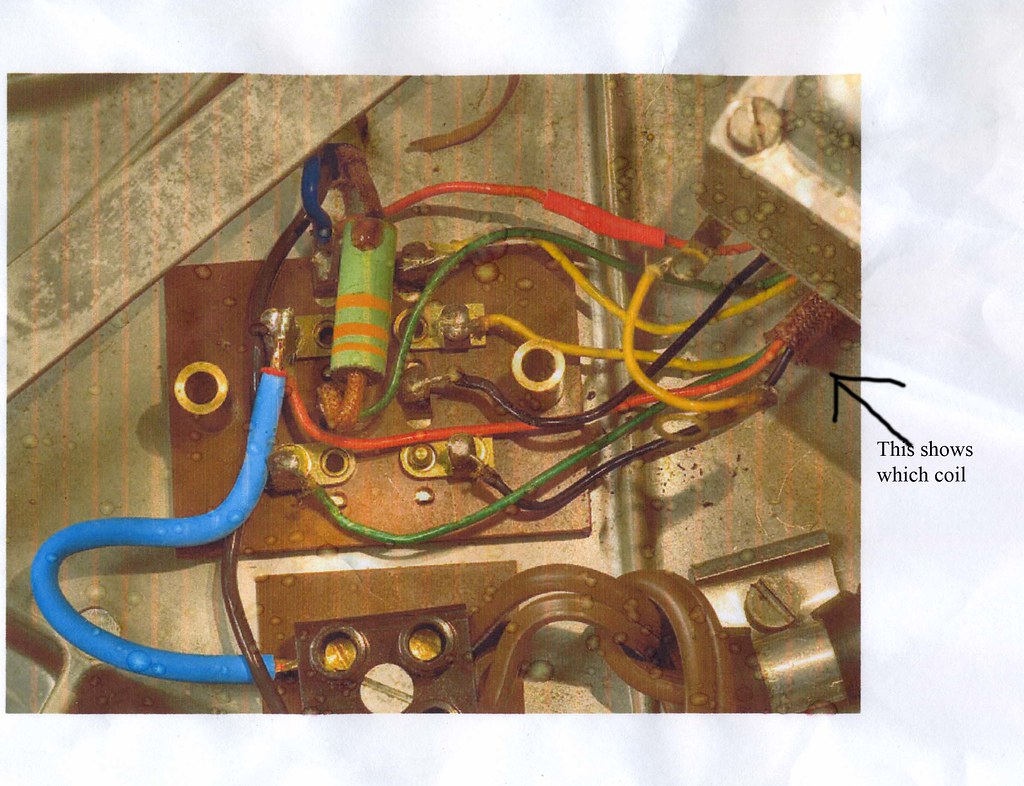

124-Motor wiring by dave_slater, on Flickr 124-Motor wiring by dave_slater, on Flickr

124-Motor wiring by dave_slater, on Flickr roger-thorens by dave_slater, on Flickr

roger-thorens by dave_slater, on Flickr