You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SME arm alignment

- Thread starter spxy

- Start date

Craig B

Re:trophile

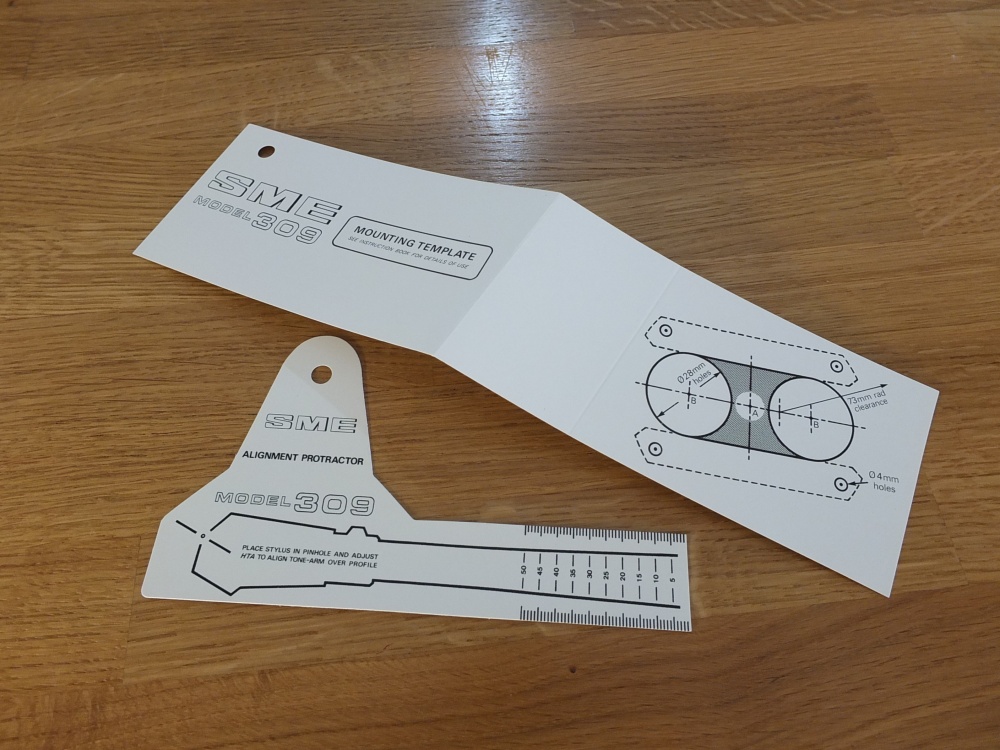

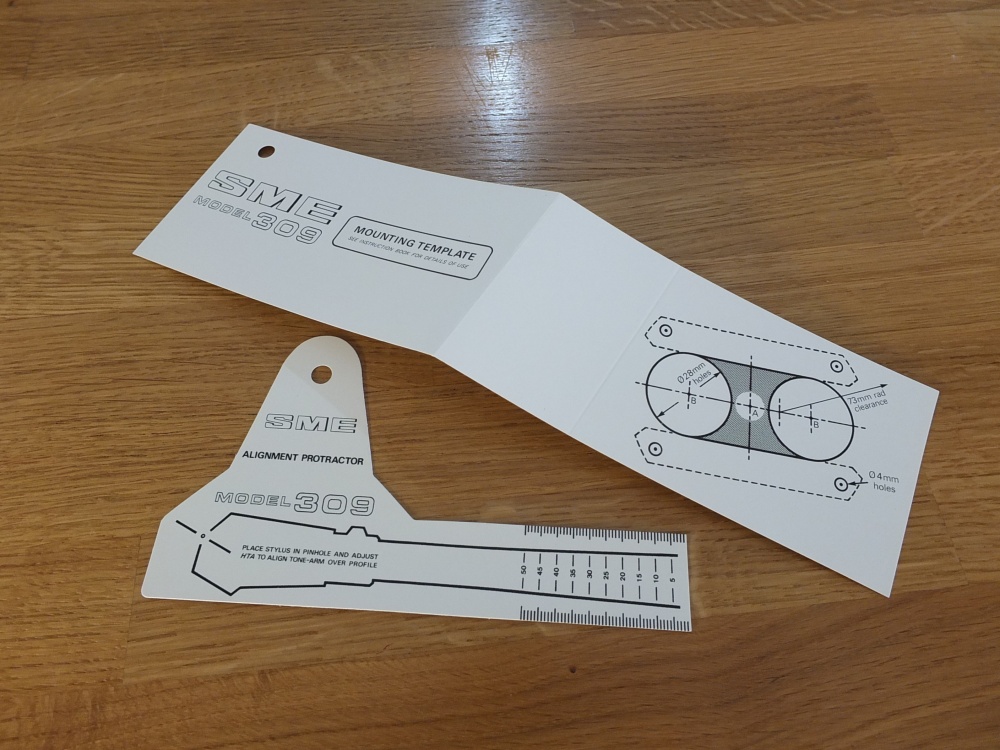

Assuming that you are referring to distance from stylus tip to the centre of mounting holes (as per Ortofon's 'E' measure of cartridge dimensions, specifically for their MC20 Super/MC30 Super MkII/HMC series) then 1mm further forward along the tonearm bedplate will get your there.

Regardless, whatever bedplate position causes the arm to align with the drawn outline on the protractor with the stylus tip resting on the target is a bullseye. Just make sure that the cartridge body is mounted properly square to the headshell offset first (there is usually a wee bit of play here).

[Image credit: Analog Seduction]

Regardless, whatever bedplate position causes the arm to align with the drawn outline on the protractor with the stylus tip resting on the target is a bullseye. Just make sure that the cartridge body is mounted properly square to the headshell offset first (there is usually a wee bit of play here).

[Image credit: Analog Seduction]

Sue Pertwee-Tyr

Accuphase all the way down

Odd, then, that SME would bother to state that the alignment protractor is based on that assumption, if the measurement makes no difference.No! Just use the protractor exactly as-is. The stylus goes on the indicated position, slide the whole arm until it is aligned. Do not worry at all about the 8.5mm/9.5mm, the alignment process corrects for this, it is the whole point of it.

No! Just use the protractor exactly as-is. The stylus goes on the indicated position, slide the whole arm until it is aligned. Do not worry at all about the 8.5mm/9.5mm, the alignment process corrects for this, it is the whole point of it.

I think that would be impossible to be correct, the alignment gauge assumes a certain distance for the centre of the mounting arm bearings to the stylus tip. If that is distance different the arc it traces across the record can not be the same.

Craig B

Re:trophile

What SME describe in the manual has more to do with them having both pivot to tip and offset fixed, with pivot to spindle being adjusted in order to facilitate overhang. They suggest that for cartridges that are other than 9.5mm from tip to mounting hole centres one may have to look down from above at a very slight angle (either from leftward or rightward) in order to see the tonearm and protractor outlines align. Had SME thought about this a bit more way back when, they would have long since recommended that the oblong arm mounting hole and bedplate be at the same angle relative to the platter as is the tonearm offset.

In reality, the difference that ±1 or 2mm of stylus to mounting hole difference will make wrt offset degrees (only) won't amount to anything.

In reality, the difference that ±1 or 2mm of stylus to mounting hole difference will make wrt offset degrees (only) won't amount to anything.

Tony L

Administrator

Odd, then, that SME would bother to state that the alignment protractor is based on that assumption, if the measurement makes no difference.

There is a theoretical issue if you get round to writing a page or two of tonearm math as the way SME arms work is to align by altering the effective length and pivot to spindle distance. It is, like all tone arm math involving a pivoted tonearm, imperfect. A compromise. It does however work very well in practice and a SME tonearm, due to its exceptional ease of use in setup, tends to end up with a very low distortion alignment. This is something for audiophiles to just follow the manual to the letter and forget about unless they are genuinely capable of understanding several pages of complex algebra and think they can second-guess SME.

There is an inherent error in all pivoted tonearms, they are remarkably imperfect things that at best are in correct alignment at two points on the record surface. The important thing IMHO is to use the arm exactly as designed, e.g. set it up with the manufacturer’s protractor and instructions. The problems come when people try to force an arm into alignment with the wrong protractor without understanding offset alignment etc.

The tldr here is just not to overthink it. SME know what they are doing, a 1mm tip to mount lug discrepancy is nothing and the whole arm slide assembly exists for exactly the reason of compensating for this. If it is aligned correctly with the SME protractor it is the best it can possibly be with this arm/cart combo. There is also a little slack in the headshell screw holes, so if being really pedantic (not necessary) then nudge the cart as far forward as it will go in this specific situation. It really isn’t a big deal. I’m prepared to bet most people here, especially those who rely on dealers to fit carts, likely have a larger error. For clarity: the error here will be a micro-fraction of a degree out of offset alignment as the effective length becomes a variable to a small degree. It is insignificant, almost certainly less than the stylus manufacturer’s own positional tolerances. To better it you’d need to get to Fremer’s oligarch-market microscopes etc. Just don’t over-think it!

PS The theoretical error here is almost certainly less than just about every old-school Linn LP12 in existence where the armboard position presents a *huge* variable (several mm) in pivot to spindle distance due to having a lot of slack in the mounting holes to the subchassis unless setup with very, very precise measurement. Which it almost always isn’t.

"They suggest that for cartridges that are other than 9.5mm from tip to mounting hole centres one may have to look down from above at a very slight angle (either from leftward or rightward) in order to see the tonearm and protractor outlines align"

I have no idea what they mean by this, if they had a diagram that would help to explain.

I have no idea what they mean by this, if they had a diagram that would help to explain.

Rockmeister

pfm Member

This:

There is a theoretical issue if you get round to writing a page or two of tonearm math as the way SME arms work is to align by altering the effective length and pivot to spindle distance. It is, like all tone arm math involving a pivoted tonearm, imperfect. A compromise. It does however work very well in practice and a SME tonearm, due to its exceptional ease of use in setup, tends to end up with a very low distortion alignment. This is something for audiophiles to just follow the manual to the letter and forget about unless they are genuinely capable of understanding several pages of complex algebra and think they can second-guess SME.

With respect, I've been trying to get a perfect alifgnement of cartidges according to every theory ever written. And only ever got to 'perfectly good and can hear no problem' but never to 'perfect' since every arm and every cartridge varies and every mounting alignement also varies.

SME understand this. Align your cartridge on the supplied point, by moving the whole arm.

Listen as hard as you can.

Re align it 1.5 away.

Listen again.

If you can hear any difference Ill send you a free award

Honestly, SME can be trusted to know how to achieve the best of all compromises.

There is a theoretical issue if you get round to writing a page or two of tonearm math as the way SME arms work is to align by altering the effective length and pivot to spindle distance. It is, like all tone arm math involving a pivoted tonearm, imperfect. A compromise. It does however work very well in practice and a SME tonearm, due to its exceptional ease of use in setup, tends to end up with a very low distortion alignment. This is something for audiophiles to just follow the manual to the letter and forget about unless they are genuinely capable of understanding several pages of complex algebra and think they can second-guess SME.

With respect, I've been trying to get a perfect alifgnement of cartidges according to every theory ever written. And only ever got to 'perfectly good and can hear no problem' but never to 'perfect' since every arm and every cartridge varies and every mounting alignement also varies.

SME understand this. Align your cartridge on the supplied point, by moving the whole arm.

Listen as hard as you can.

Re align it 1.5 away.

Listen again.

If you can hear any difference Ill send you a free award

Honestly, SME can be trusted to know how to achieve the best of all compromises.

Paul R

pfm Member

You cannot get an SME 'correct' for any cart with a different mount/tip distance to their assumption. This is because when you move the arm base the correct offset angle should change, but SME arms don't allow you to twist the cart in the mount (significantly). But you can get it close enough. Just follow the instructions.

For many, many years now Linn have supplied dealers with a tool to allow the arm base to be put in the correct position. The template that came/comes with Linn arms allows you to put the stylus at the correct distance from the pivot with the arm off the deck. This means it's easy to get the designed alignment on an LP12. Whether the designed alignment is optimal is a whole other story.

For many, many years now Linn have supplied dealers with a tool to allow the arm base to be put in the correct position. The template that came/comes with Linn arms allows you to put the stylus at the correct distance from the pivot with the arm off the deck. This means it's easy to get the designed alignment on an LP12. Whether the designed alignment is optimal is a whole other story.

Rockmeister

pfm Member

Well now you have someone to blame when you hear no difference. Win win!LOL SME actually say to view the cartridge from a different angle if the mounting distance if different, they just don't clearly explain how to do this....its their fault

Yank

Bulbous Also Tapered

Is the accuracy of the SME alignment method affected by the location and angle of the tonearm mounting hole? I see many SMEs installed on bases that are too small to locate the elongated hole according to SME's template. Many of them don't even point in the same direction.

Tony L

Administrator

Is the accuracy of the SME alignment method affected by the location and angle of the tonearm mounting hole? I see many SMEs installed on bases that are too small to locate the elongated hole according to SME's template. Many of them don't even point in the same direction.

Assuming you get the centre in the right place there should be enough movement. Some turntables are pretty tight space wise, though the mounting sled movement is absolutely huge, at least +/- 15mm, and really all it is needed to do is compensate for the +/- 1 or maybe 2mm widely used by cartridge manufacturers.

Here’s a picture of my TD-124 & 3009 Series II. It is pretty tight, the mount is as far back as it can go on the armboard, and the sled still ends up past the half-way point with a typical cart, but even so there is more than enough movement given the tiny discrepancies between cartridges. On a Garrard the situation is usually reversed as the chassis is so large the arm mount needs to sit a little further away unless mounted right at the back, as such the arm tends to end up fairly far forward in the sled. It doesn’t matter, the movement range is huge and way more than would ever be needed. It is one of many things I really like about SME arms, the mounting position doesn’t need to be perfect the way it is on so many decks as it is an adjustable parameter. The level of precision required to drill an armboard exactly for a fixed pivot arm is beyond most people/dealers skillset and I’m sure often ends up wrong.

sktn77a

pfm Member

This is my understanding, too (from my old 3009/S2 days).No! Just use the protractor exactly as-is. The stylus goes on the indicated position, slide the whole arm until it is aligned. Do not worry at all about the 8.5mm/9.5mm, the alignment process corrects for this, it is the whole point of it.

Huh??? That's the first I've heard of this(?)You cannot get an SME 'correct' for any cart with a different mount/tip distance to their assumption.

Tony L

Administrator

Huh??? That's the first I've heard of this(?)

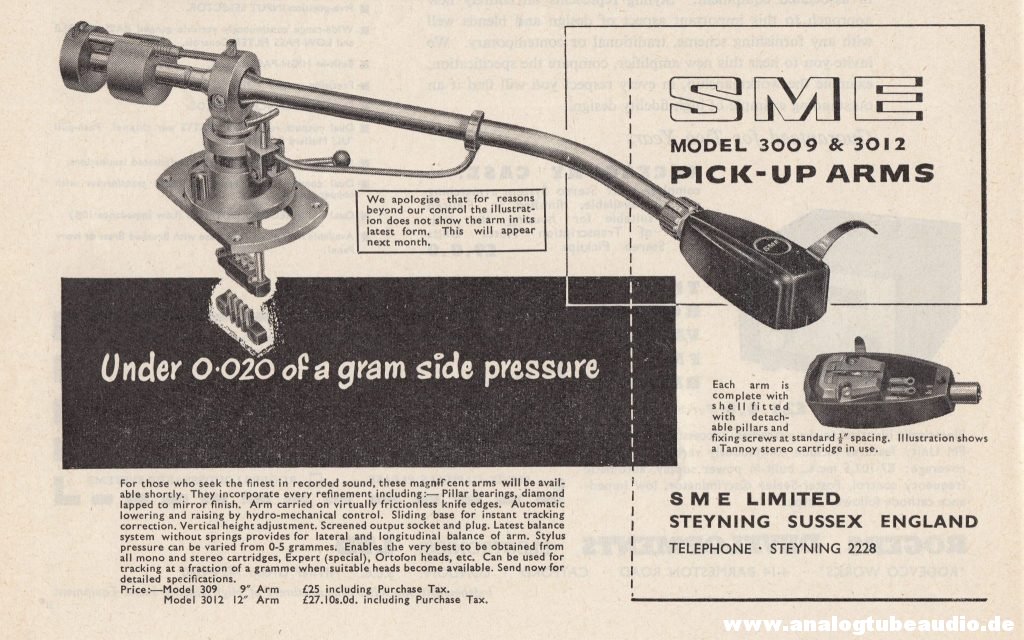

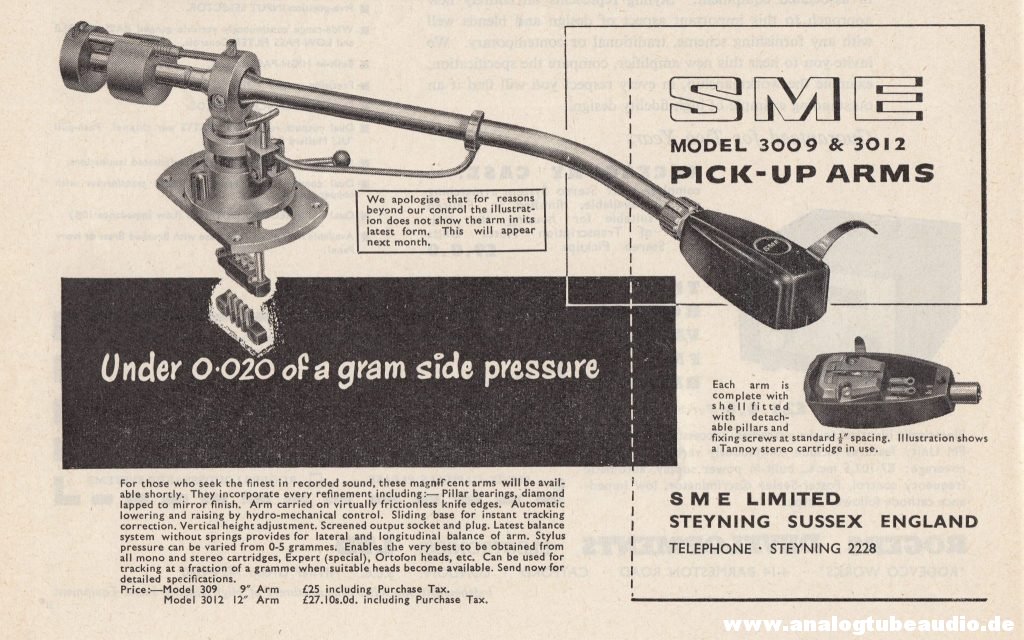

He is technically correct. The reason being the pivot to spindle distance is not set in stone due to the moving baseplate, therefore the offset angle changes depending on position. In practice given the stylus to mount lugs varies by only a mm or two between brands the change of angle is imperceptible in real terms. This is a classic ‘audiophiles overthinking things thing’. The classic A R-A era SME were the best engineering and design company the world of tonearm design has ever seen. They literally wrote the rule book back in 1959 with the original 3009 and 3012 which have to be amongst the most copied items anywhere in audio history. They got it right. The conceptual compromise in alignment was actually a really good one as ease of use is so much better and by making things so simple it helps negates user/dealer-error (which is a real issue based on how many poorly aligned turntables I’ve encountered over the years).

Craig B

Re:trophile

Let us not forget that the SME prototypes had more than a hint of Ortofon about them. There's was even what might have been a wee Freudian slip included in the 9" arms model designation in the original ad below (Ortofon's 12" model designations ended with 309, i.e. they were 309mm).

Tony L

Administrator

That art impression never got anywhere near production to my knowledge. The Ortofon-style sprung tracking force was never used, and that picture doesn’t even appear to have knife-edge bearings! It is very much a picture from an art department to my eyes.

The original arms as released were where everything came together. An arm where static balance, VTF, VTA, alignment, azimuth (and very slightly later) anti-skate could each be adjusted independently from any other adjustment (so few arms meet this even today!) and a beautifully damped cueing device was provided. As a piece of ergonomic design it was so far from the future it is hard to comprehend. One of the most iconic and groundbreaking items to be found anywhere in audio.

The original arms as released were where everything came together. An arm where static balance, VTF, VTA, alignment, azimuth (and very slightly later) anti-skate could each be adjusted independently from any other adjustment (so few arms meet this even today!) and a beautifully damped cueing device was provided. As a piece of ergonomic design it was so far from the future it is hard to comprehend. One of the most iconic and groundbreaking items to be found anywhere in audio.