I finally bought a 3012 which I will use on a 301. When checking it over the rear appeared to be sagging so thought the coupling may have perished. I twisted the end cap off (ruining the coupling rubber in the process) and can see the spigot is slightly bent upward. Is this by design? It is not drastic but cant’t imagine how one would cause a bend like that given how carefully most people would treat something so delicate. I have Googled it and found a couple of posts related to the bend but does anyone know if this is usual? Any recommendations for someone that can service at reasonable cost? Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tony L

Administrator

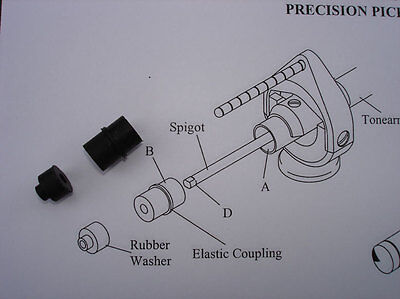

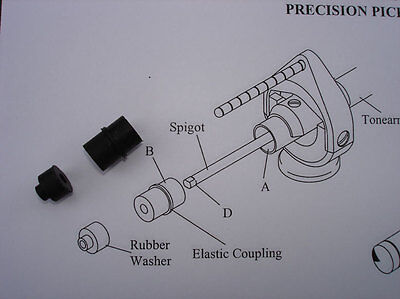

Always been straight on the ones I’ve seen. The diagram in the SME diagram is straight too. Visible in this eBay advert:

That said there is something different about the design of early split-weight examples, and I’m not ripping one apart to see what it is!

SME 3009,3012, Coupling Rubbers & Service Sheet NOS BRITISH MADE SME PRODUCT | eBay

This Service Sheet guides the user through the complete installation process.

www.ebay.co.uk

That said there is something different about the design of early split-weight examples, and I’m not ripping one apart to see what it is!

This site contains affiliate links for which pink fish media may be compensated.

Craig B

Re:trophile

It is possible that SME intentionally angled the spigot slightly upward on 3012 in order to pre-compensate for the inevitable sag that such heavier weights applied might result in with rubber coupling (i.e. with the mass loaded outer end stub tube settling level over the mean lifetime of the rubbers).

sktn77a

pfm Member

DON'T. When you break it, you'll just say "I wish I'd left it alone".Might just tweak it straight.

Ask me how I know!!!