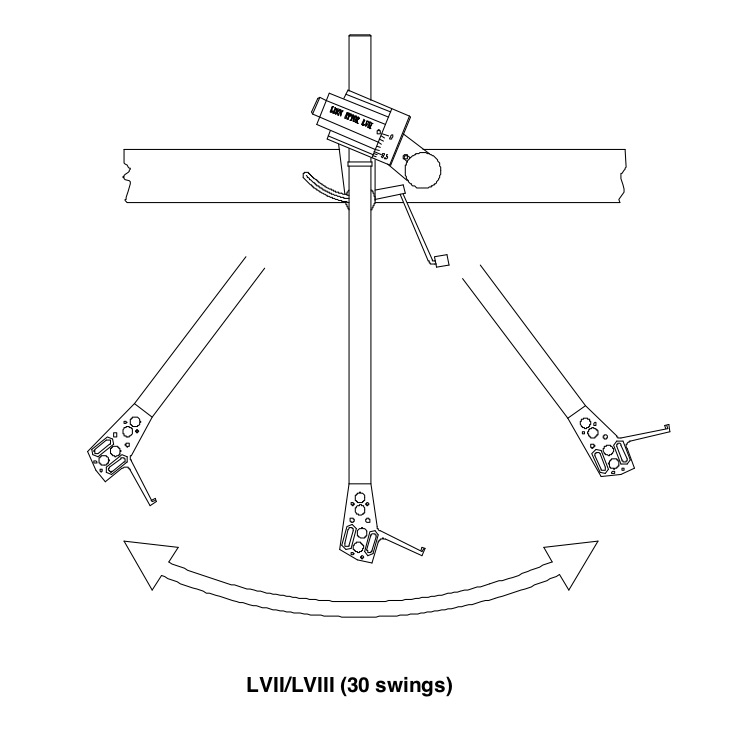

I managed to pick up a nice early LP12 with a split counterweight Ittok LVII a couple of weeks back. Unfortunately the arm has been subjected to typical Linn cartridge tightening procedures, so the paint is damaged. Rather than going down the touch-up route, has anyone attempted removing the headshell altogether, stripping (or prepping) and respraying?

It looks as thought it's just held in with a couple of screws on the underside of the armtube, and presumably some thread-lock or adhesive. Can't quite see in the link below if the headshell connectors are soldered on the armtube side (I imagine so), so perhaps I'd consider an internal rewire at the same time. https://www.ebay.co.uk/itm/22478373...d=link&campid=5338728743&toolid=20001&mkevt=1

Welcome any thoughts.

It looks as thought it's just held in with a couple of screws on the underside of the armtube, and presumably some thread-lock or adhesive. Can't quite see in the link below if the headshell connectors are soldered on the armtube side (I imagine so), so perhaps I'd consider an internal rewire at the same time. https://www.ebay.co.uk/itm/22478373...d=link&campid=5338728743&toolid=20001&mkevt=1

Welcome any thoughts.

This site contains affiliate links for which pink fish media may be compensated.