You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rega RB110 tonearm vertical bearings torque specs

- Thread starter vicdiaz

- Start date

pocketkitchen

Registered User

Have you dismantled it? You should be able to pull the new cabling through using the old as a guide. If you've dismantled it, I'm not sure where you'll get the specs from as Rega don't publish them.

Craig B

Re:trophile

Rega have reported that the same team produce 125 complete Planar 1 units per day. IOW, they assemble 125 RB110 tonearms and 125 decks!

As such, I would suspect that the assembly process for RB110 is geared toward speed, with zero play rather than ultra-specific pre-load as ultimate goal.

As such, I would suspect that the assembly process for RB110 is geared toward speed, with zero play rather than ultra-specific pre-load as ultimate goal.

pocketkitchen

Registered User

The tonearm dept is separate to the turntable one but I can't imagine them not doing it to a certain spec. If they don't then it won't matter but if they do, then I can't imagine they'll publish the numbers anyway. Maybe drop them a line and ask if they can repair it?Rega have reported that the same team produce 125 complete Planar 1 units per day. IOW, they assemble 125 RB110 tonearms and 125 decks!

As such, I would suspect that the assembly process for RB110 is geared toward speed, with zero play rather than ultra-specific pre-load as ultimate goal.

Joolzdee

pfm Member

The tonearm dept is separate to the turntable one but I can't imagine them not doing it to a certain spec. If they don't then it won't matter but if they do, then I can't imagine they'll publish the numbers anyway. Maybe drop them a line and ask if they can repair it?

+1 for this.

Can't see Rega charging an arm (no pun intended!) and a leg to re-wire it either.

Craig B

Re:trophile

I suspect they are separate for the rest of the turntable line, however, due to demand, this is not the case with Planar1/RB110.The tonearm dept is separate to the turntable one but I can't imagine them not doing it to a certain spec. If they don't then it won't matter but if they do, then I can't imagine they'll publish the numbers anyway. Maybe drop them a line and ask if they can repair it?

http://www.rega.co.uk/rega-factory-tour.htmlRega Research Ltd. said:Planar 1 turntable production - Planar 1 Turntable and RB110 tonearm

Current demand requires a skilled team of 8 people to build a minimum of 125 units every single day. The same team also make the same quantity of RB110 tonearm. This high level of demand, required a huge investment from Rega to build a new department to house production on this scale.The success of this product has continued since launch and the simple set up of this plug & play design is an easy step back in to the world of vinyl for many users.The only thing entry level about this handmade turntable is the price.

Last edited:

pocketkitchen

Registered User

Fair enough. If the arm has a fault, my feeling would be to send it back to them and get it returned to spec, though.I suspect they are separate for the rest of the turntable line, however, due to demand, this is not the case with Planar1/RB110.

http://www.rega.co.uk/rega-factory-tour.html

I would be very surprised if there was a torque for the RB110, or any other Rega arm for that matter. It's one of those things where feel is the best tool for the job. If you get the arm so there is no play in the bearings but it's floating as freely as it does with play, you can't get any better than that. It's not very difficult.

Craig B

Re:trophile

Here is the closest thing Rega has published on their site that indicates the amount of preload applied to their tonearm bearings.

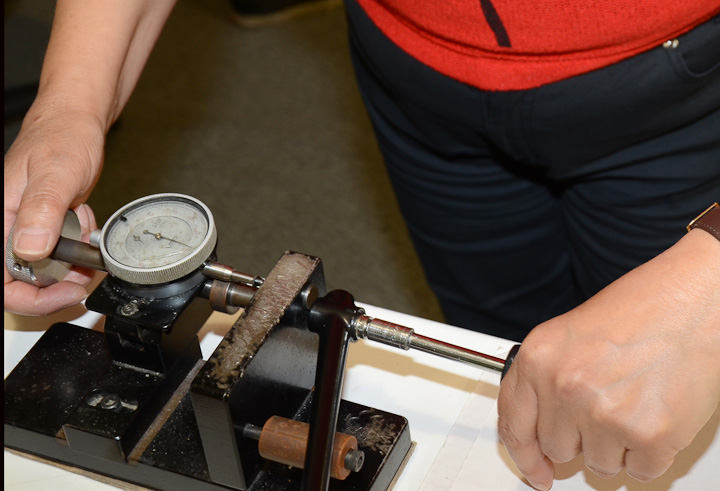

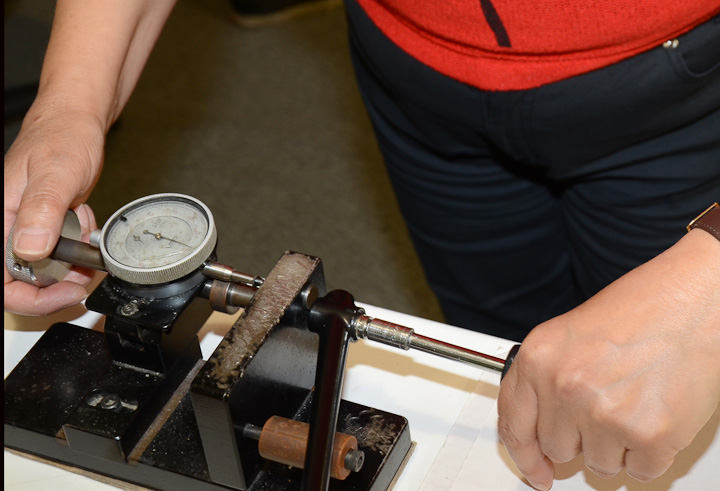

Below is a photo of one of Rega's vertical bearing adjustment jigs being demonstrated to visitors from The Absolute Sound, circa 2013. Note the dial indicator used to set microns of travel past initial contact, aka preload. I suspect that the technique involves gently making contact with the bearings by feel, setting the dial indicator to zero, and then turning through an additional specified micron or two of travel, via reference to the gauge, as a means to eliminate radial play over the life of the tonearm.

Compare the above micron tolerances with that mentioned in the Rega 'The Importance of Zero Play' missive and one might assume ~2 microns for RB110.

Here is a illustration of the dynamics of applying preload, in this case, the application of an axial load across a pair of bearings for the purpose of removing free internal clearances.

Below is a photo of one of Rega's vertical bearing adjustment jigs being demonstrated to visitors from The Absolute Sound, circa 2013. Note the dial indicator used to set microns of travel past initial contact, aka preload. I suspect that the technique involves gently making contact with the bearings by feel, setting the dial indicator to zero, and then turning through an additional specified micron or two of travel, via reference to the gauge, as a means to eliminate radial play over the life of the tonearm.

The Absolute Sound said:Using this assembly fixure, experienced workers very carefully pre-tension tone arm bearings (RB303 bearings are tensioned to 1 micron tolerances, whilst RB808 and RB1010 bearings are said to be adjusted to sub-1-micron tolerances)

Compare the above micron tolerances with that mentioned in the Rega 'The Importance of Zero Play' missive and one might assume ~2 microns for RB110.

Here is a illustration of the dynamics of applying preload, in this case, the application of an axial load across a pair of bearings for the purpose of removing free internal clearances.

Last edited:

Hazelberry

sister

I've done exactly this with an RB300 that came with slightly playful bearings. Sounded so much better afterwards.I would be very surprised if there was a torque for the RB110, or any other Rega arm for that matter. It's one of those things where feel is the best tool for the job. If you get the arm so there is no play in the bearings but it's floating as freely as it does with play, you can't get any better than that. It's not very difficult.

Same here with an NAD-badged one.

The NAD ones I've seen looked to be exactly the same as Rega-badged ones. All of the arms seem to be the same with the exception of Goldring. The bearings on those were so far out I have to conclude it was deliberate to reduce the performance of the arm. Even then, once you adjusted the bearings they were fine, same as any other RB250.

Mr Pig, it was you who bought the Goldring arm from me wasn't it, the one that needed a rewire? If so I remember you commenting that the bearings seemed a little loose compared to a "proper" Rega-badged item and you had to adjust them. It would make sense that Rega "detuned" them slightly, certainly the rest of the deck was slightly less nice than a Rega 2, which fitted with it being a bit cheaper.