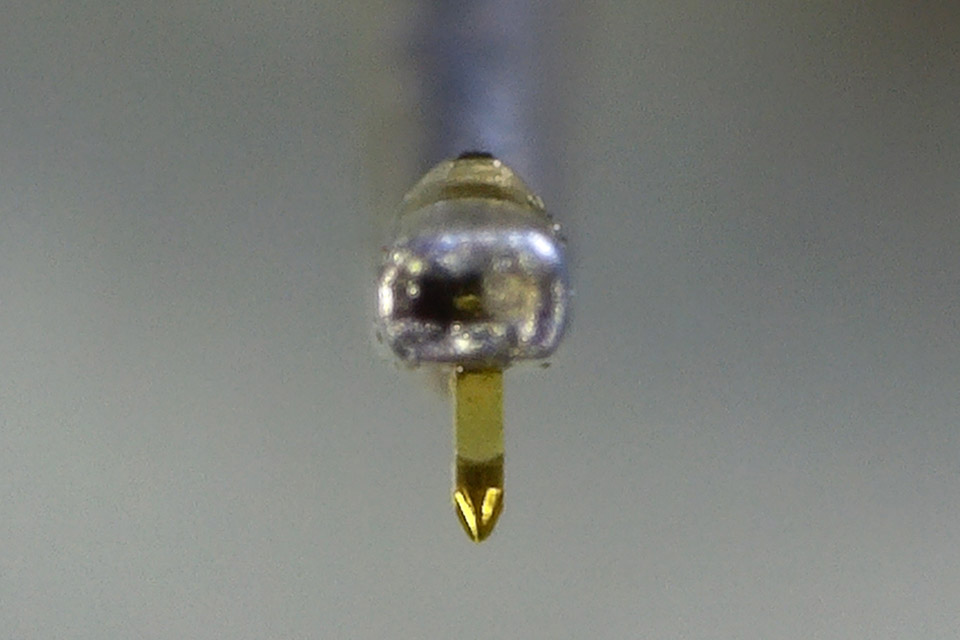

The more surface area the better really, although it is the distribution of the contact patch area that makes the biggest difference when it comes to both information retrieval and reducing wear (of both stylus tip and record groove). This has nothing to do with the orientation of the stylus profile wrt the major and minor rectangle dimensions of these Vital type diamond blocks; more a case of what the major and minor tip radii are (

R vs

r). Typically, a fine line tip will have far more diamond contact with the groove walls vertically, with more or less the same area contacting the groove walls horizontally as the über-ellipticals of old (Shure's 0.2mil

r of their old ED tips, for example). This vertical elongation/extension of the contact patch means that contact patch area is greater than that of even a large conical (say 0.7mil), something that typically lasts a good while longer than a standard elliptical (circa 500hrs vs. 300hrs according to A-T, see P.S. below), where some of the fore and aft portions of the same contact area have been ground away during manufacturing in order to better trace the HF undulations within the groove walls. Because fine line/extended line contact type tips also spread the load over a much larger area this also results in both reduced stylus and record wear. Another thing that you are likely to hear about is 'grain oriented' diamonds; this referring to the hardest sides of the diamond being presented to the record groove walls.

Within the graphic below, you'll notice that 0.5mil conical has greater contact surface area than a standard elliptical (typically 0.3 x 0.7mil these days), with line contact types having far greater contact area than even the 0.7mil conical (despite line contact types typically having smaller minor radii (

r) than most ellipticals).

P.S. Although there are many factors at play, audio-technica suggests the lifetime of their styli to be approx. 300 to 500 hours for Conical, 300 hours for Elliptical, 1000 hours for Microlinear, and 800 hours for Shibata and Special Line Contact.