-alan-

pfm Member

Not sure if this is the right subforum.. but..

I have a Triumph Motorbike with an electronic speedo/instrumentation panel. You can do clever things on it like toggle menu buttons to access numerous functions and/or customise the main display(s).

Unfortunately, the buttons have stopped toggling (well, never did in my ownership), which is a bit of pain because the fuel level reporting function is buried somewhere in the inaccessible menus. A well known problem on the machine (675 Daytona) apparently.

I got a quot of 120 euro plus vat for a repair from a specialist repair tech place. Since I had to take the clocks out to bring it for repair, I thought I would have a look and see whether there were any obvious signs of trouble that I could potentially repair myself, and save the outlay.

Managed to get the clocks open, and remove the main printed circuit board inside for a look. Took some pics to help get a closer look - and there do seem to be some signs of trouble. I was wondering if anybody could have a look at the pics and advise - which of the dodgy looking parts are likely to be reason for concern, and whether there is anything your average home hacker might be able to have a go at fixing without highly specialised tools and kit please ?

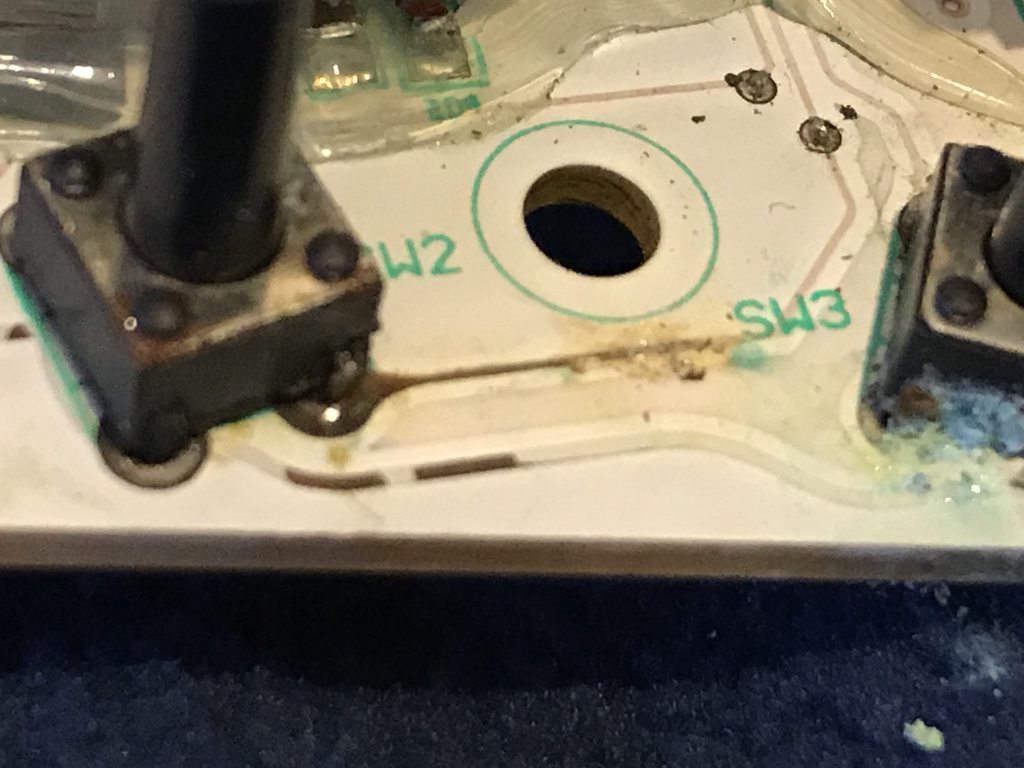

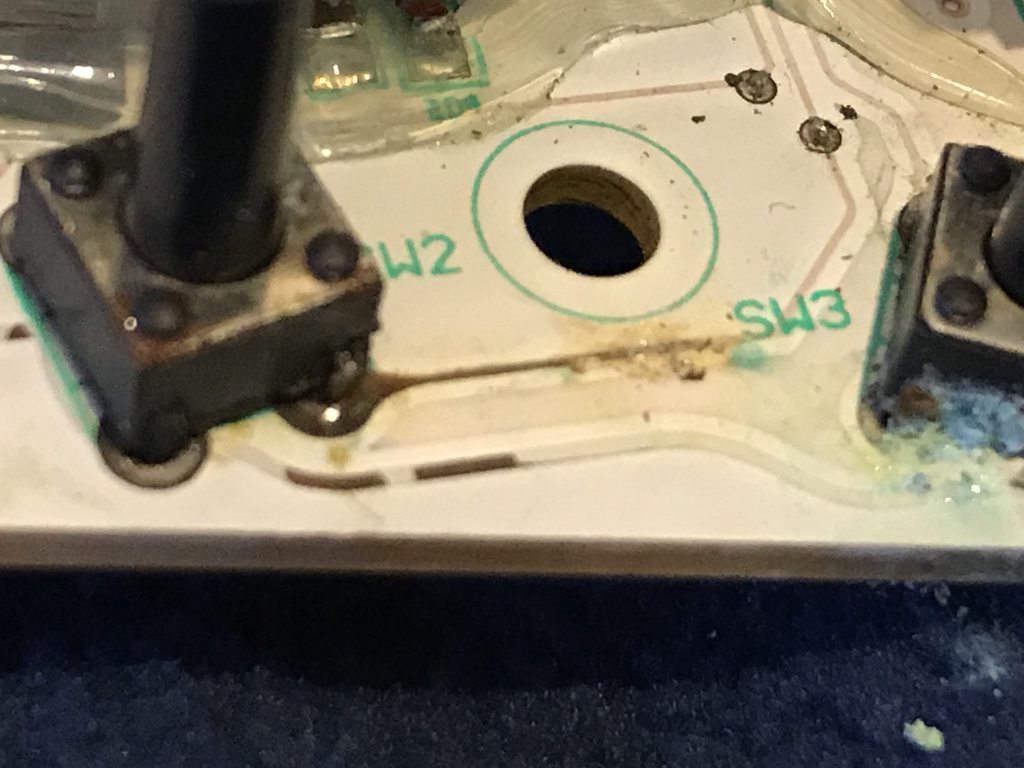

Front of the PCB and (what I thought at least were) some questionable looking components and circuitry:

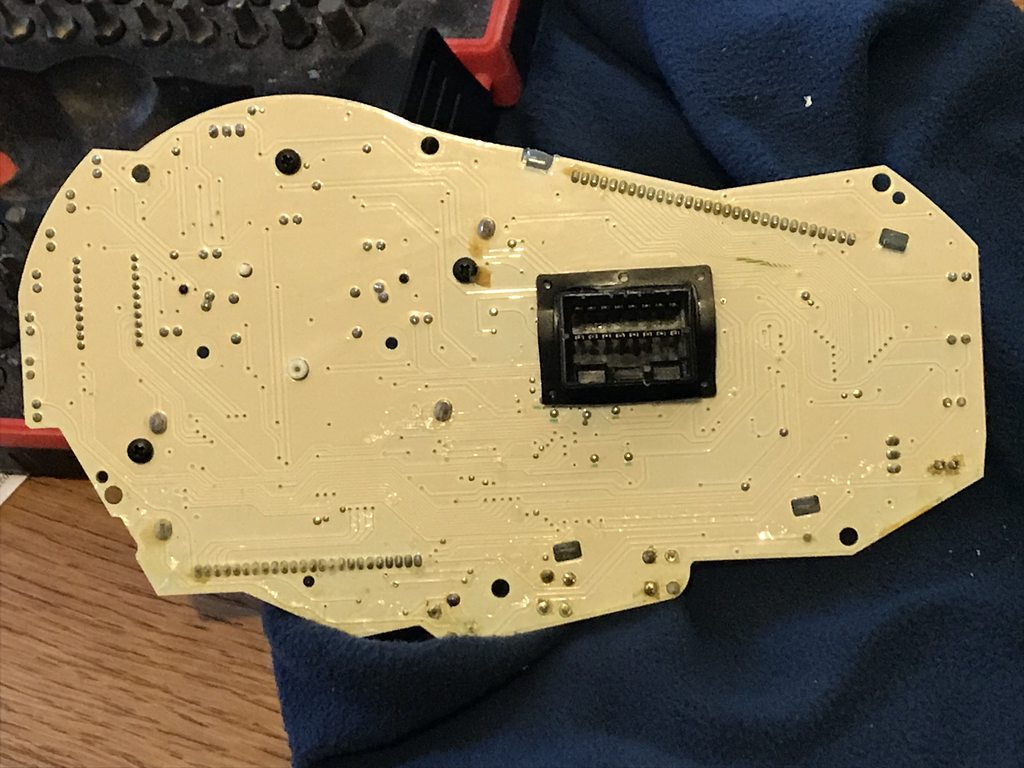

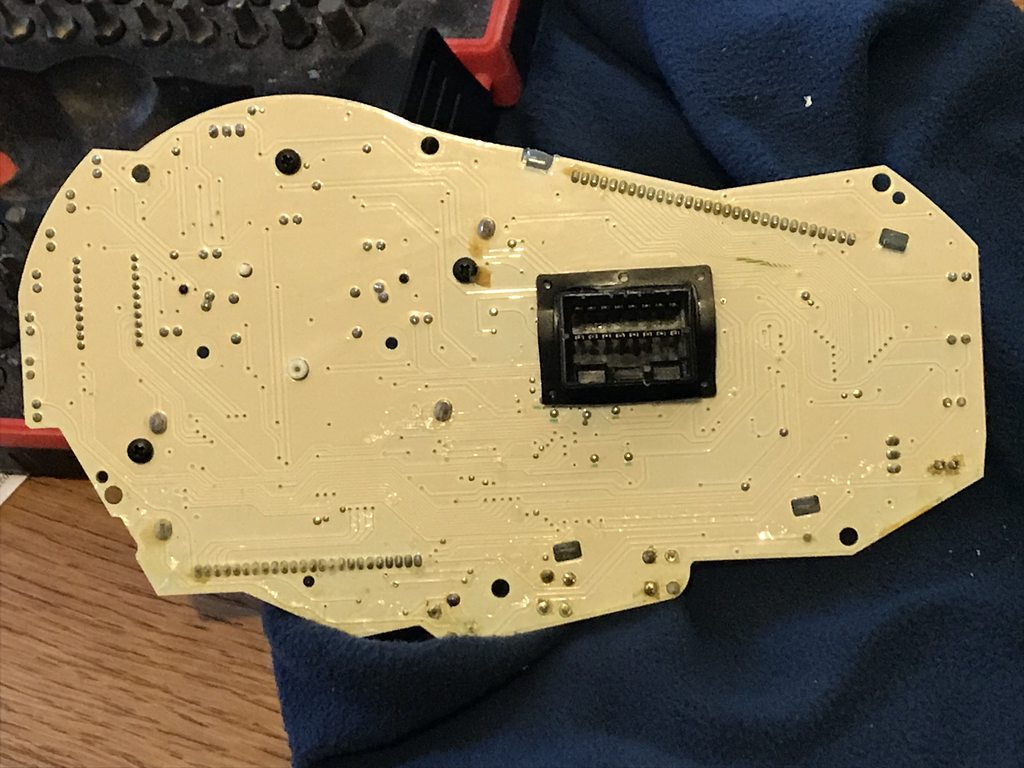

Rear of the PCB - and same, some of what I thought were dodgy bits:

Apologies for the brain dump and image dump - but any info or advice greatly appreciated.

Thanks, Alan

I have a Triumph Motorbike with an electronic speedo/instrumentation panel. You can do clever things on it like toggle menu buttons to access numerous functions and/or customise the main display(s).

Unfortunately, the buttons have stopped toggling (well, never did in my ownership), which is a bit of pain because the fuel level reporting function is buried somewhere in the inaccessible menus. A well known problem on the machine (675 Daytona) apparently.

I got a quot of 120 euro plus vat for a repair from a specialist repair tech place. Since I had to take the clocks out to bring it for repair, I thought I would have a look and see whether there were any obvious signs of trouble that I could potentially repair myself, and save the outlay.

Managed to get the clocks open, and remove the main printed circuit board inside for a look. Took some pics to help get a closer look - and there do seem to be some signs of trouble. I was wondering if anybody could have a look at the pics and advise - which of the dodgy looking parts are likely to be reason for concern, and whether there is anything your average home hacker might be able to have a go at fixing without highly specialised tools and kit please ?

Front of the PCB and (what I thought at least were) some questionable looking components and circuitry:

Rear of the PCB - and same, some of what I thought were dodgy bits:

Apologies for the brain dump and image dump - but any info or advice greatly appreciated.

Thanks, Alan