flatpopely

Prog Rock/Moderator

Yeah, but that's not really an effective way to balance the load - you'd be better just adding more weight at the other two springs.

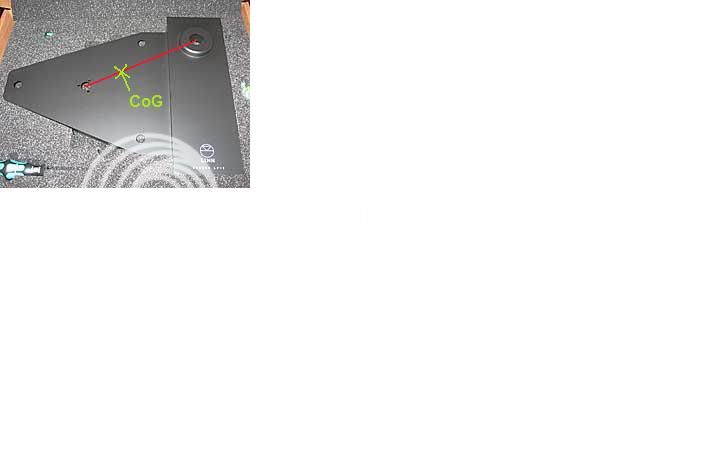

I don't understand what you mean by this. How would weighting up the rear and left hand spring counter the effect of a reduced armboard weight over the front spring?