per-Sony-fied

Me in another jacket

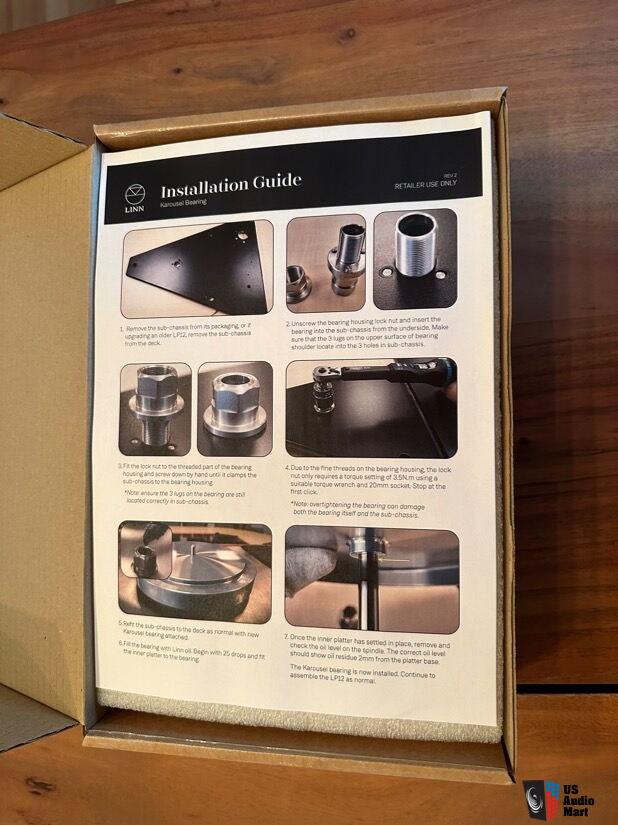

It seems the torque settings for the Karousel have been all over the place since its introduction. Are these current torque settings set by Linn published somewhere?

Finger tightness? Not sure there’s a torque wrench that goes that low,

This image pinched off the web which comes in the Karousel box & states 3.5Nm. There are plenty of torque wrenches that work that low.

This document/instructions is REV2. I notice also on the web there is another revision document that states 4Nm for all modern LINN Subchassis & 5Nm for the older pressed steel type. This appears to be be the original revision 1