You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flux removal from PCB

- Thread starter 337alant

- Start date

david ellwood

Kirabosi Kognoscente

I miss trychloroethylene.

john.luckins

pfm Member

Acetone is very effective on flux but can dissolve some plastics so a little risky/aggressive.

Yank

Bulbous Also Tapered

Acetone is very effective on flux but can dissolve some plastics so a little risky/aggressive.

If there's a parts layout silkscreened on the board the acetone could take that off too.

Would naphtha be any less risky?

jhmee9

Active Member

Just use more IPA after brushing, get soak piece of cotton with IPA and...voila!What are you guys using for flux removal from a PCB

Ive got most of it off with IPA and a stiff plastic brush, but it still feels a bit tacky

Anyone tried detergent and water?, no capacitors fitted at present only resistors diodes and transistors

Alan

Avoid Acetone...too aggressive...

Washing PCB with detergent and warm water is OK...

Industrially, everything is aqueous. You just need the right surfactant and process.

Rosin - the base of most fluxes, is a mixture of mostly long-chain acids, so a mild alkali, which very many surfactants, and soaps in particular, are, should help.

I've never tried it, but how about baking soda - a try can do no harm. Flush well after trying.

Rosin - the base of most fluxes, is a mixture of mostly long-chain acids, so a mild alkali, which very many surfactants, and soaps in particular, are, should help.

I've never tried it, but how about baking soda - a try can do no harm. Flush well after trying.

percival007

Member

It seems barely legal - it does not tell you what is in it on the data sheet, that it is just "a blend of solvents". The fact that it is "extremely flammable" rings alarm bells - there is no such classification - legally something is flammable or not, toxic or not, corrosive or not, etc.

john.luckins

pfm Member

All that information appears in safety data sheet .pdf further down the product page. Do you think that helps make it more legal?

S-Man

StrivingON

What are you guys using for flux removal from a PCB

Ive got most of it off with IPA and a stiff plastic brush, but it still feels a bit tacky

Anyone tried detergent and water?, no capacitors fitted at present only resistors diodes and transistors

Alan

I use IPA. It usually takes 2 or 3 passes and it's important to wipe as much of the "solution" off the board before it dries. In effect this waters (IPAs) down the flux each time.

Tony L

Administrator

Likewise 99% isopropyl (I always have loads of it around for record cleaning solutions) sprayed on and brushed with a toothbrush (bought specially, not the one in use!) and then some more isopropyl on a cloth gets most of it off, though it takes a lot of time to get a really clean non-sticky finish.

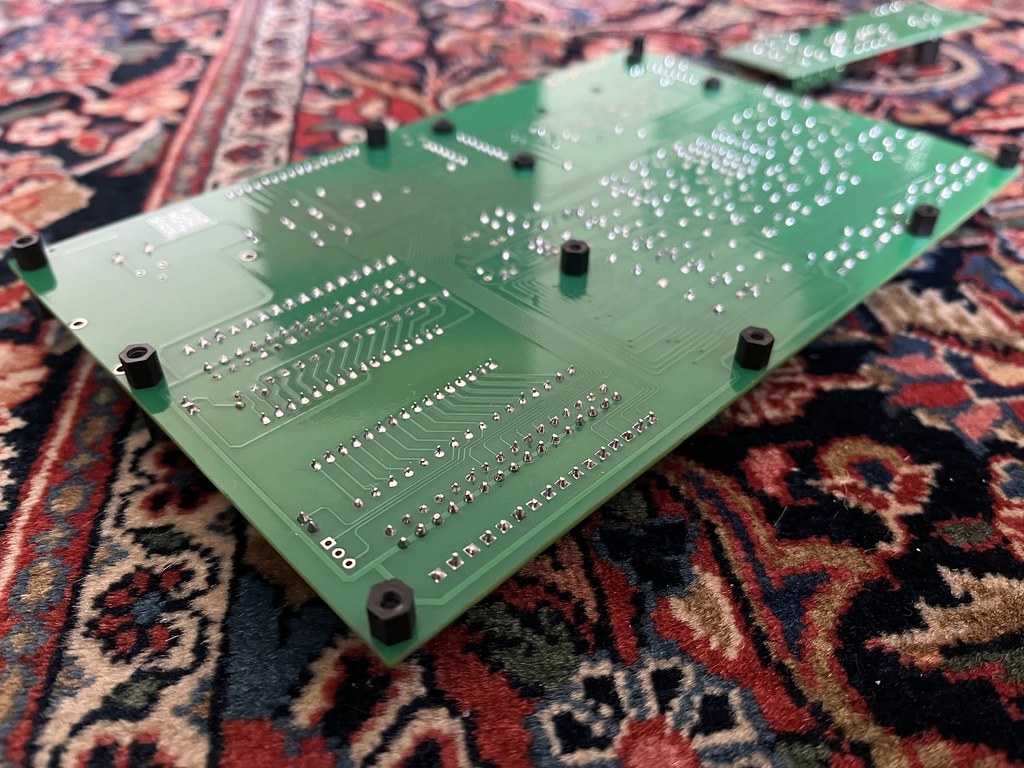

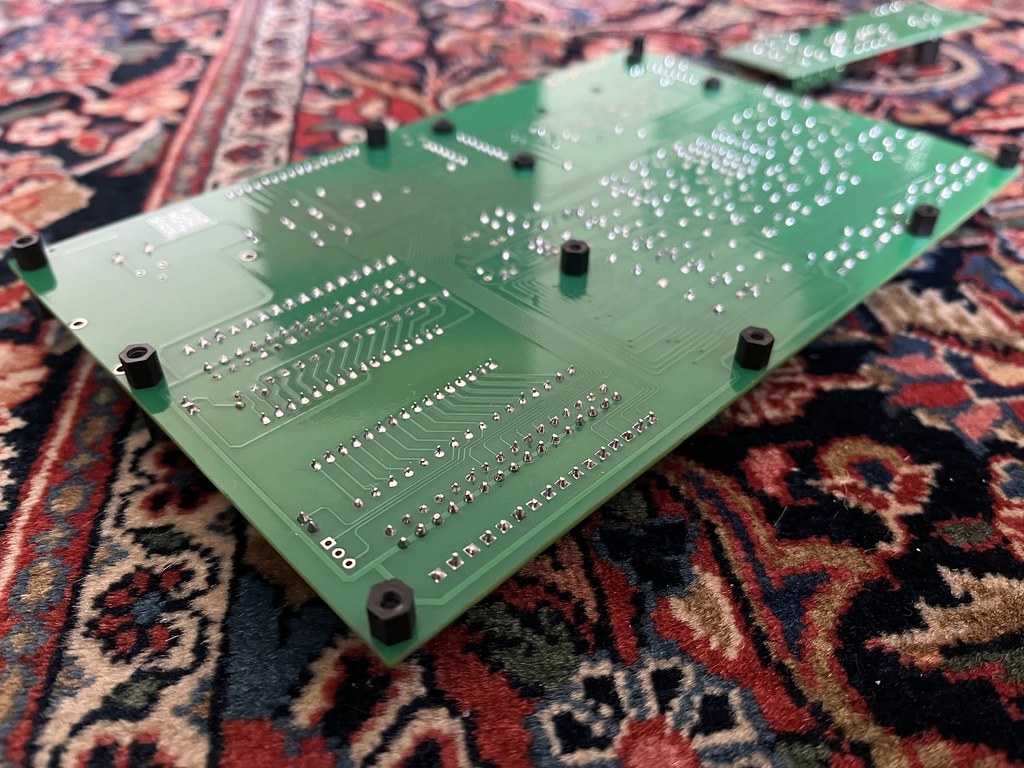

I spent almost as much time cleaning this Retro Chip Tester board up as I did making it!

With simple boards washing them up is the quickest approach IME, though very rare you can get away with it as there is so often at least one thing on the board you can’t safely immerse, e.g. a pot, relay, transformer or whatever. If it is just resistors, caps etc I just wash it in the sink! I did that with my fully populated Leak TL12 Plus tag-boards before sticking them back in the amps.

I spent almost as much time cleaning this Retro Chip Tester board up as I did making it!

With simple boards washing them up is the quickest approach IME, though very rare you can get away with it as there is so often at least one thing on the board you can’t safely immerse, e.g. a pot, relay, transformer or whatever. If it is just resistors, caps etc I just wash it in the sink! I did that with my fully populated Leak TL12 Plus tag-boards before sticking them back in the amps.

All that information appears in safety data sheet .pdf further down the product page. Do you think that helps make it more legal?

You'd have to look up the MSDS for each declared component, but most are generic and some are just repeats - propan-2-ol, iso propanol and iso-propyl alcohol are just different names for CH3- CHOH- CH3. The glycol ether is perhaps the most questionable - many are unpleasant or worse.

Industrially, for very simple, general degreasing/cleaning purposes, there used to be available "mixed solvents", which I would guess was a mixture from distilled waste solvents - bung stuff into a still, warm, condense, sell the resultant random mixture of solvents. I would assume that this is still available - the sellers just have to be careful about it not containing things like benzene, trike, genklene etc., but they are so very very rarely used and tightly controlled these days.......................

It does say that it may lift some coatings, which could easily be due to the variable nature of it.

Yes! This is fundamentally true of all solvent based cleaning processes.I use IPA. It usually takes 2 or 3 passes and it's important to wipe as much of the "solution" off the board before it dries. In effect this waters (IPAs) down the flux each time.

Otherwise you're simply dissolving the <dirt>, then letting the solvent evaporate, re-depositing the <dirt>.

337alant

Negatively Biased

OK thanks for all of your responses

Looks like I just need to repeat the process a couple of times with the IPA

Think I will try a final flush with warm water as well

I also have a big bottle of record cleaner which could be good for the final rinse as its just IPA distilled water and a touch of surfacant

Alan

Looks like I just need to repeat the process a couple of times with the IPA

Think I will try a final flush with warm water as well

I also have a big bottle of record cleaner which could be good for the final rinse as its just IPA distilled water and a touch of surfacant

Alan

337alant

Negatively Biased

For info,

Just had a mail from LesW and he says he uses Safewash Super followed by a warm water rinse

Alan

Just had a mail from LesW and he says he uses Safewash Super followed by a warm water rinse

Alan

Looks to be a water/alcohol mix with some surfactant, so basically record cleaning solution. I find straight IPA then actually soak up the resulting IPA with a paper cloth gets things to a pretty good state. Saying that, the sort of crud you discover under any surface mount components even having doused with IPA and scrubbed does make me wonder whether i'm really just pushing stuff around more than i'd like. But the board looks ace...For info,

Just had a mail from LesW and he says he uses Safewash Super followed by a warm water rinse

Alan

My recent old computer purchase, a Mac IIcx I stuck the motherboard in the sink and used washing up liquid as they tend to get old capacitor leakage on them, and the risk of killing some component or other was outweighed by the benefit of making sure no tracks would randomly dissolve in the next few years.