Dowser

Learning to bodge again..

So, one of my 63s is prone to intermittent clicking/ticking - quite unobtrusive currently, & not aggressive sounding (I only hear it between tracks), and switching speaker off for 5 minutes restores operation to normal.

The ticking/clicking coincides with the neon flashing & is coming from the top left hand side of the speaker.

I guess I need to do something about it...

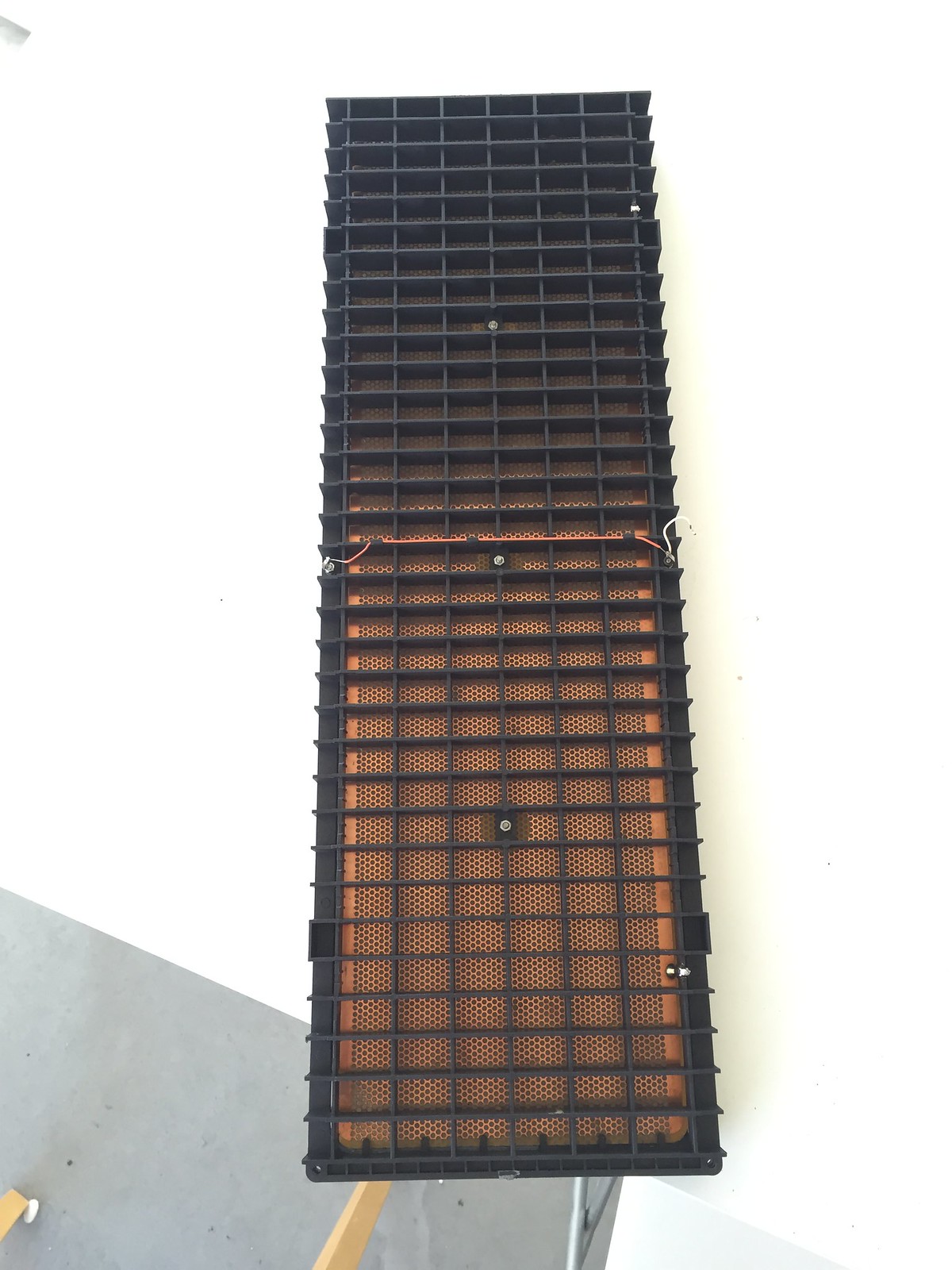

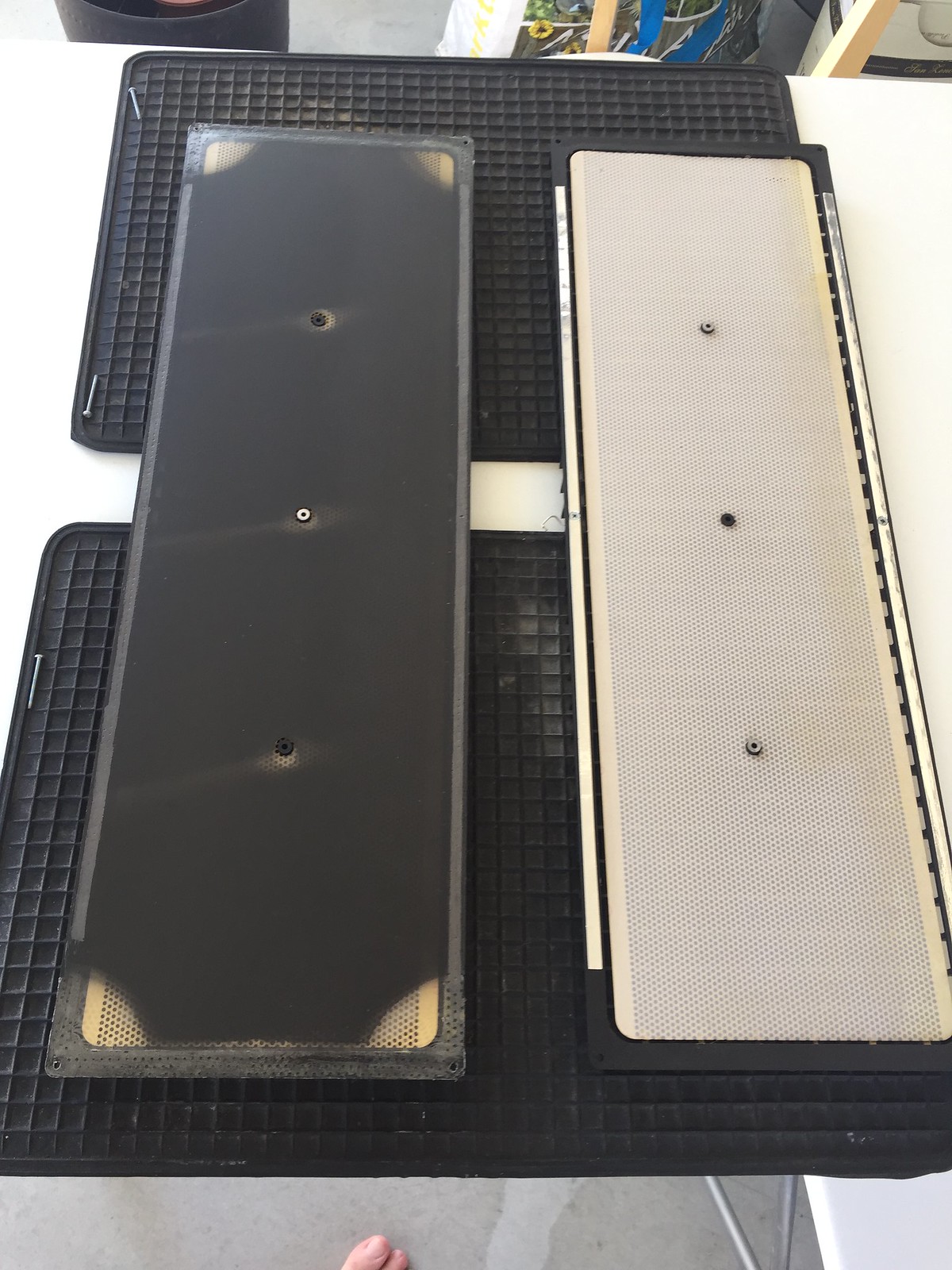

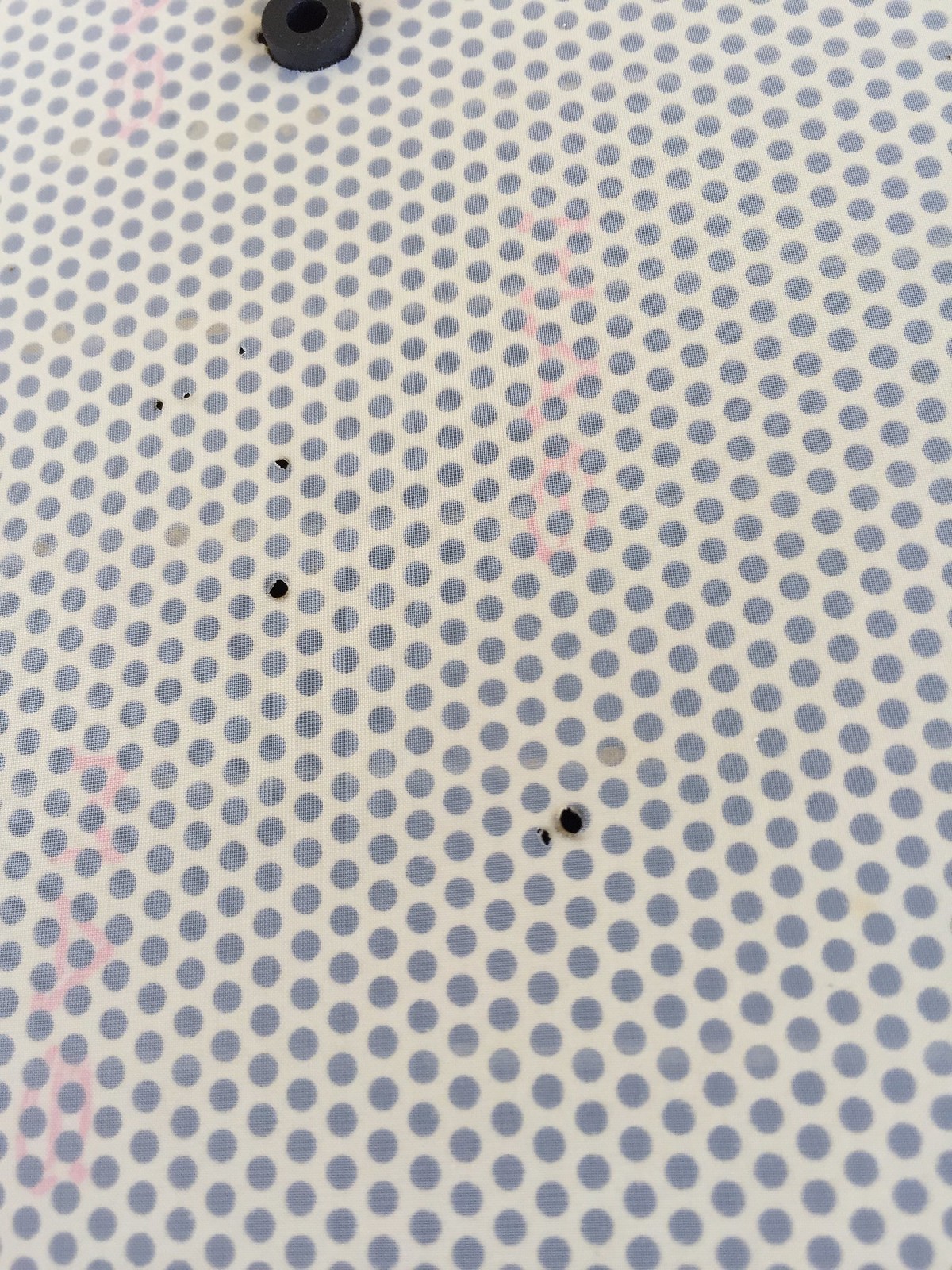

Reading up a little bit, I understand the common problem on 63 panels is the glue joint between stator on outer plastic panel failing, and the stator then interfering with the mylar coated film. Does anyone know whether this causes the ticking/clicking issue I have?

I assume, to do the job properly, I should remove all panels and re-glue any suspect panels - as a preventative measure to stop further future failures -internet info suggests this is possible without damaging the panel, has anyone actually done it?

I also plan on changing the socks at some point - has anyone done this, and do you need to completely separate the whole base (with electronics) from the frame holding the panels. Assuming yes, may as well do them at same time.

It all sounds like quite a lot of work, that will take a few evenings/weekends to achieve...time like this I wish I'd kept my 57s too

Last question - do Quad themselves still supply 63 panels? Anyone know the cost? Otherwise - best place to get original style panels? I would rather only change 1 panel if that is all that has failed, but if the sound changes then should at least look at doing one panel on each speaker.

Thanks, Richard

The ticking/clicking coincides with the neon flashing & is coming from the top left hand side of the speaker.

I guess I need to do something about it...

Reading up a little bit, I understand the common problem on 63 panels is the glue joint between stator on outer plastic panel failing, and the stator then interfering with the mylar coated film. Does anyone know whether this causes the ticking/clicking issue I have?

I assume, to do the job properly, I should remove all panels and re-glue any suspect panels - as a preventative measure to stop further future failures -internet info suggests this is possible without damaging the panel, has anyone actually done it?

I also plan on changing the socks at some point - has anyone done this, and do you need to completely separate the whole base (with electronics) from the frame holding the panels. Assuming yes, may as well do them at same time.

It all sounds like quite a lot of work, that will take a few evenings/weekends to achieve...time like this I wish I'd kept my 57s too

Last question - do Quad themselves still supply 63 panels? Anyone know the cost? Otherwise - best place to get original style panels? I would rather only change 1 panel if that is all that has failed, but if the sound changes then should at least look at doing one panel on each speaker.

Thanks, Richard