I am trying to get original parts ready for Jeffs NAP250 clone and found his thread about BUV20s here. The BUV20s I received yesterday look exactly like the ones shown here, even the packaging looks exactly as on those pictures:

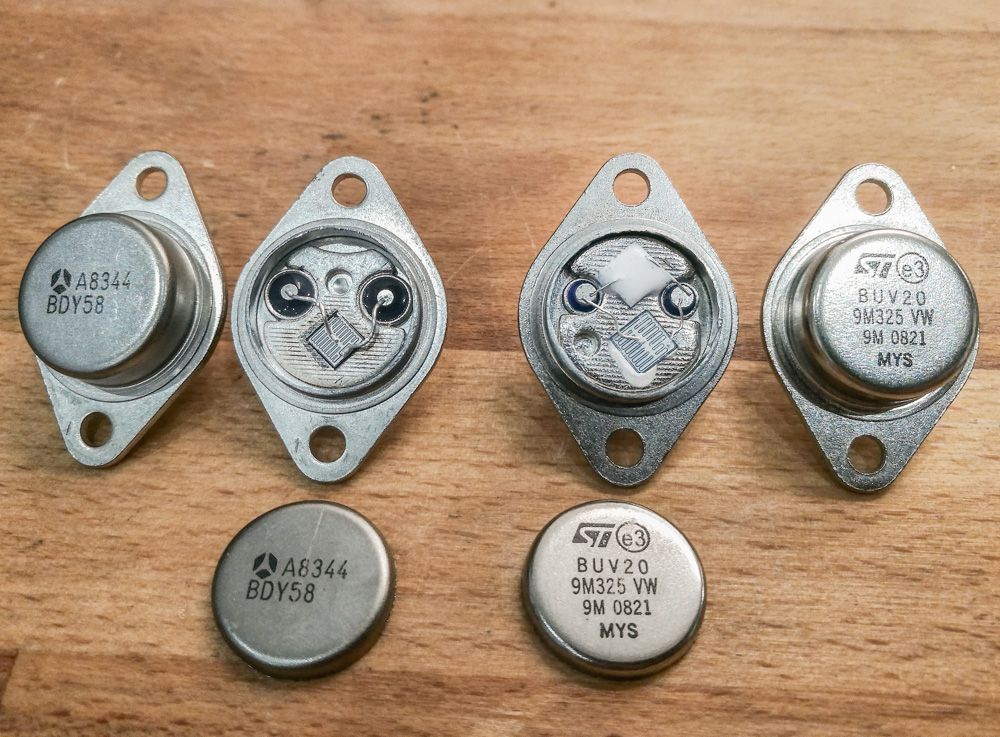

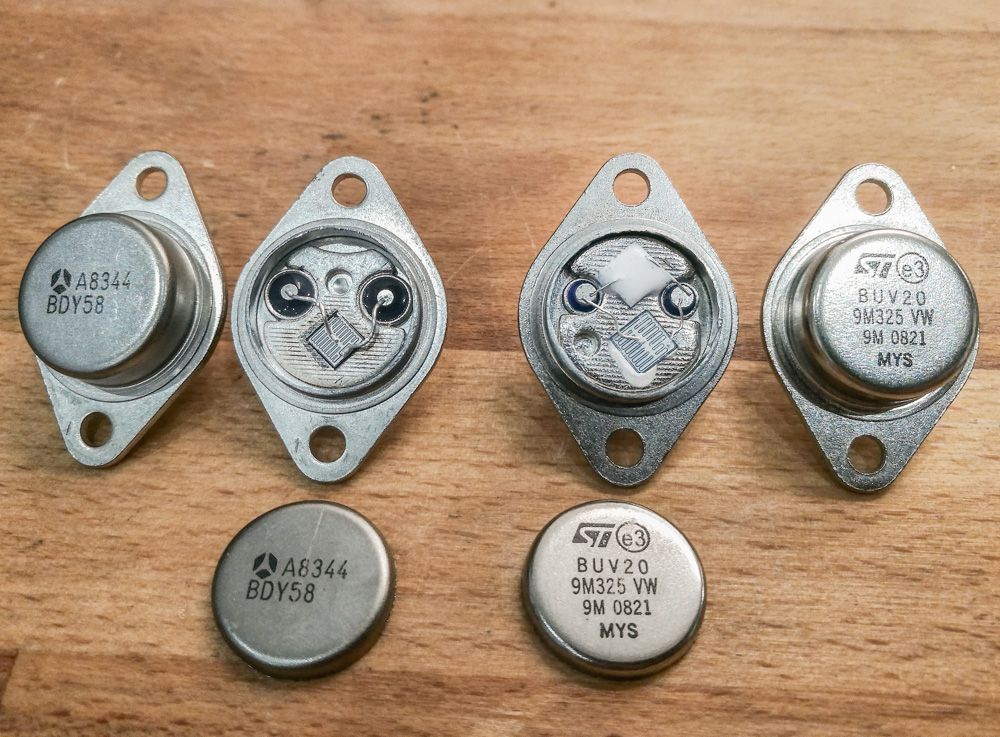

The BUV20s look a bit too new. The printing on one of them I could remove with aceton (but not with alcohol). It seems there are still new old stock ones available, and I will be happy to supply a link, but first I would like to make sure they are genuine. I also got some small signal transistors from the same source and BDY58s. Here some more pictures:

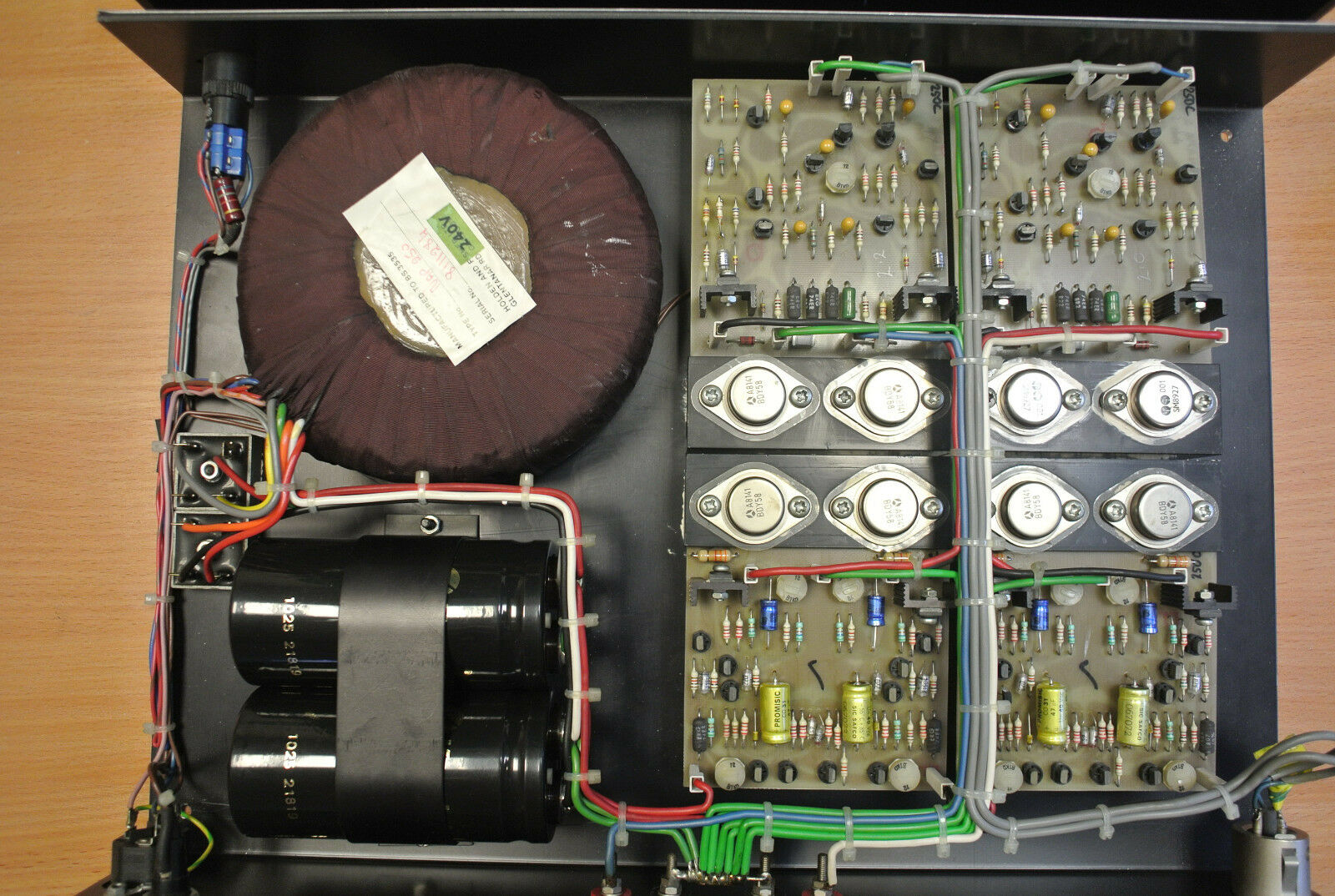

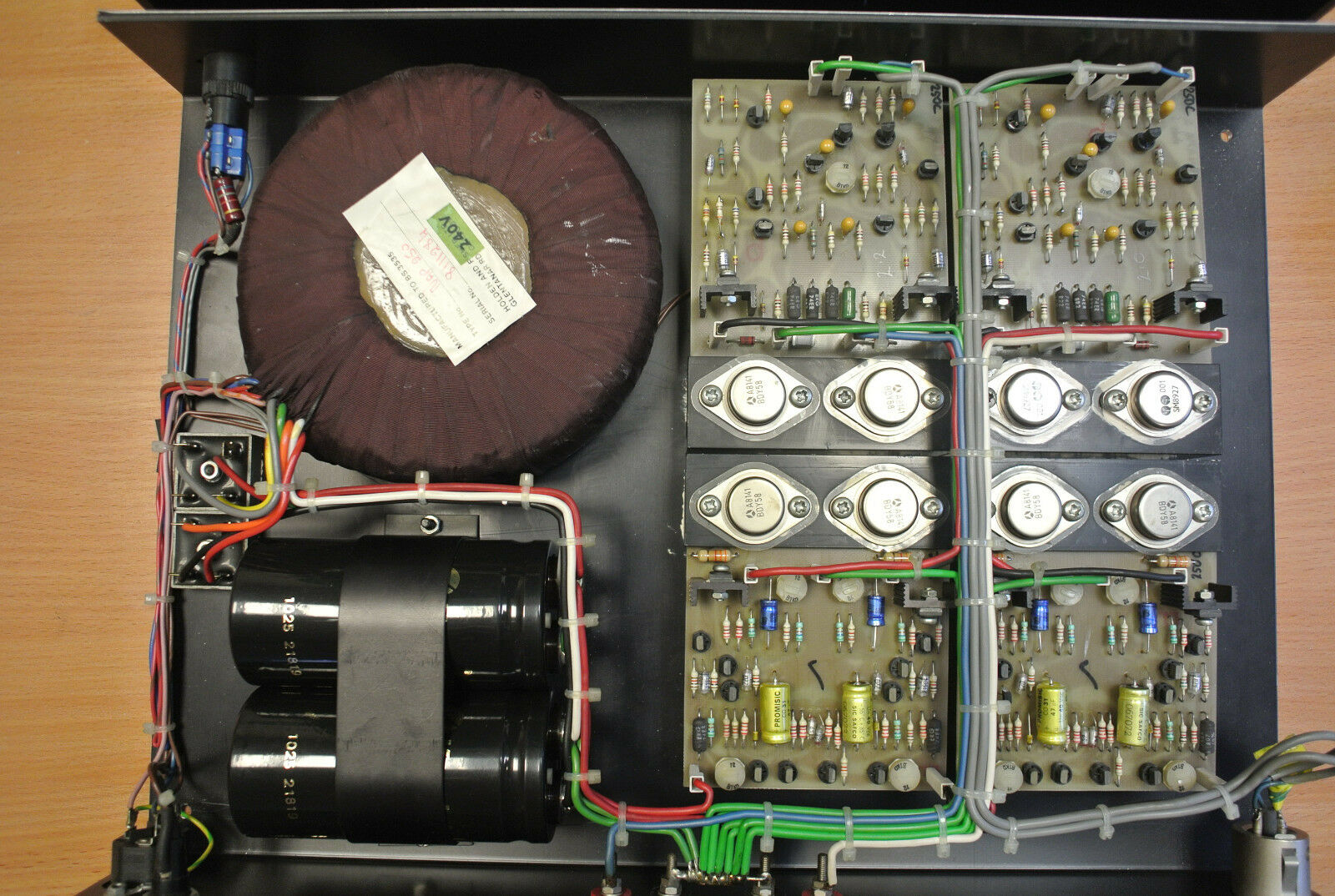

BUV20 and BDY58 opened with my lathe. The printing on the BDY58 cannot be removed with aceton. The BDY58 has 1mm pins (some show faint corrosion) and looks exactly like the ones on these pictures of an old NAP250 I found online:

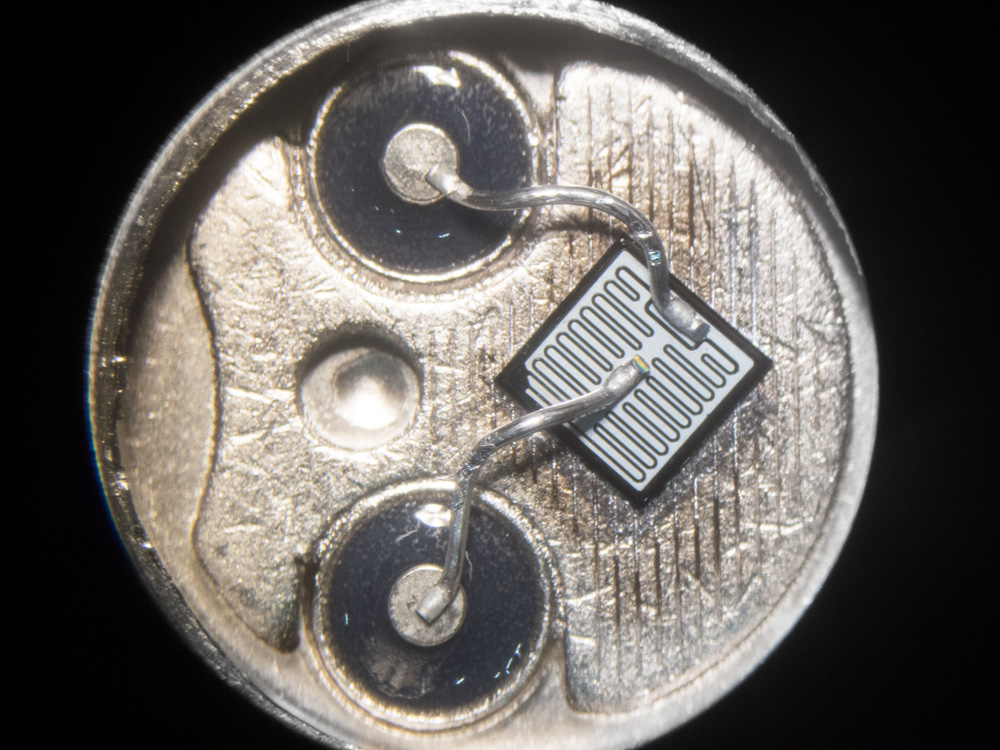

Here a closeup of the BDY58 I opened:

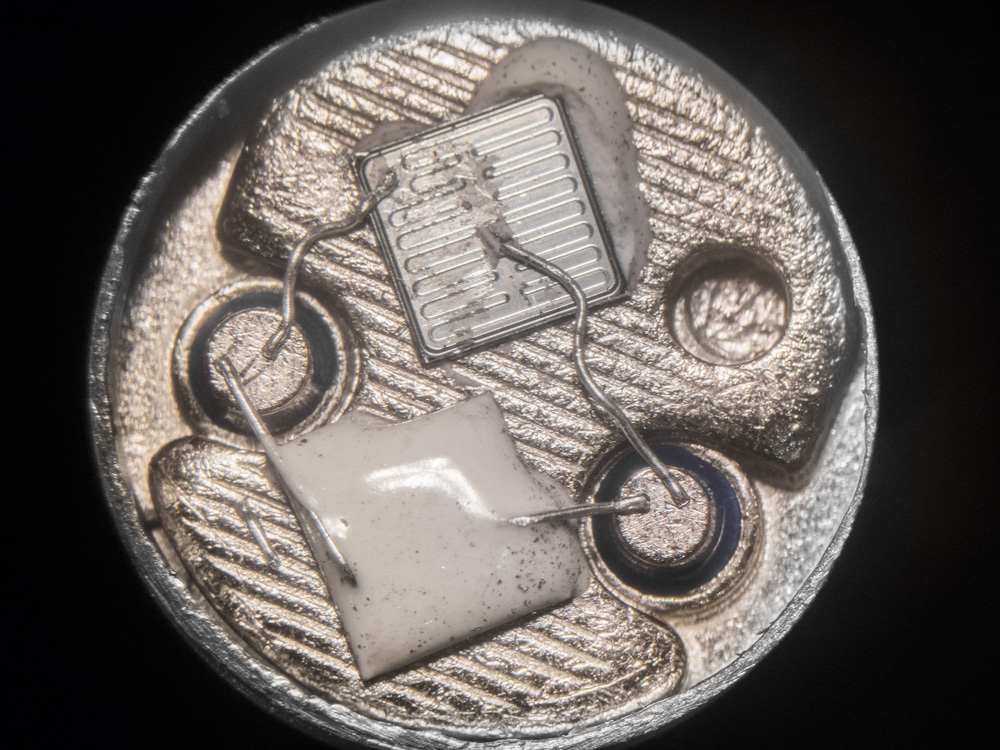

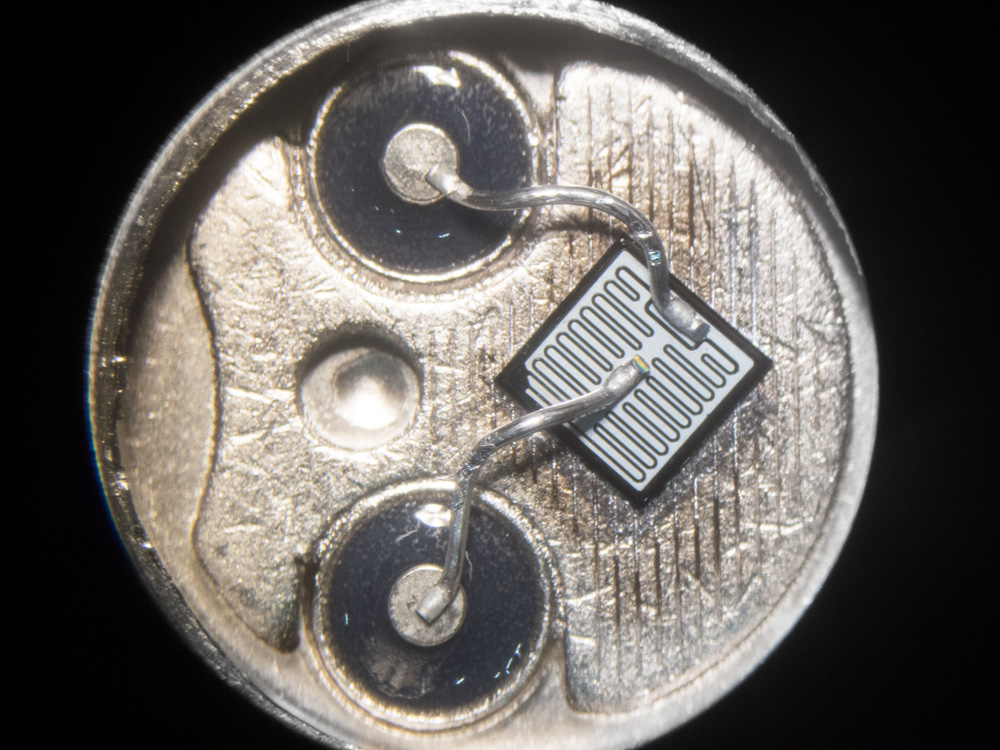

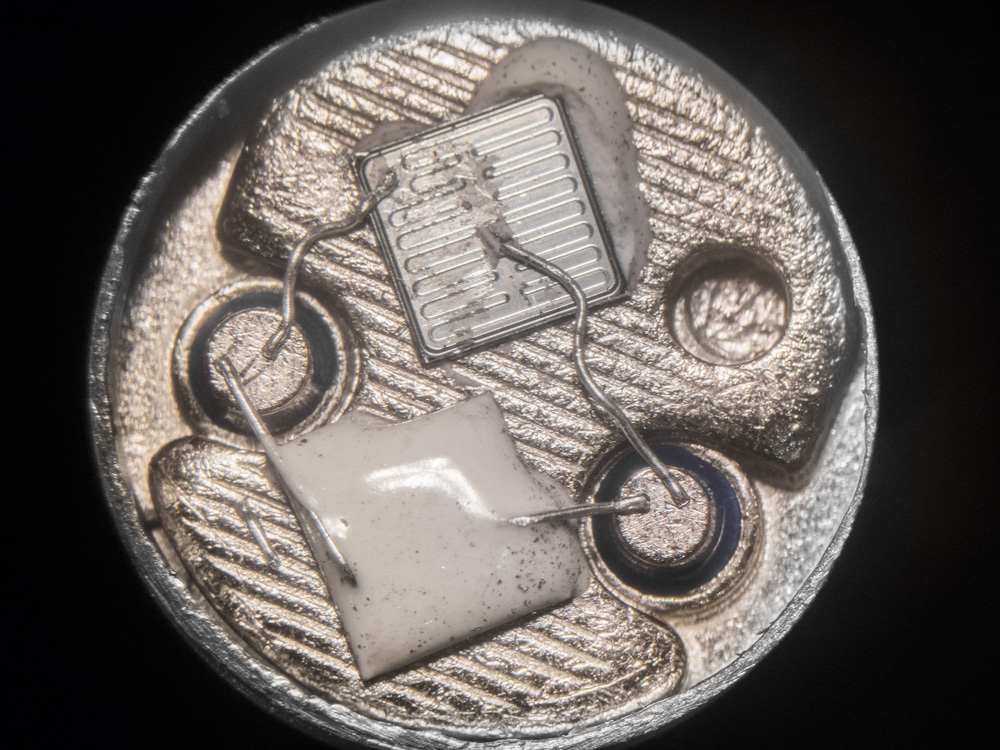

My BUV20 has 1.48~1.5mm thick pins. I scratched off the white protection from one die with my finger nails:

The die looks a bit damaged because I was not very careful when sratching off the white rubber-like stuff:

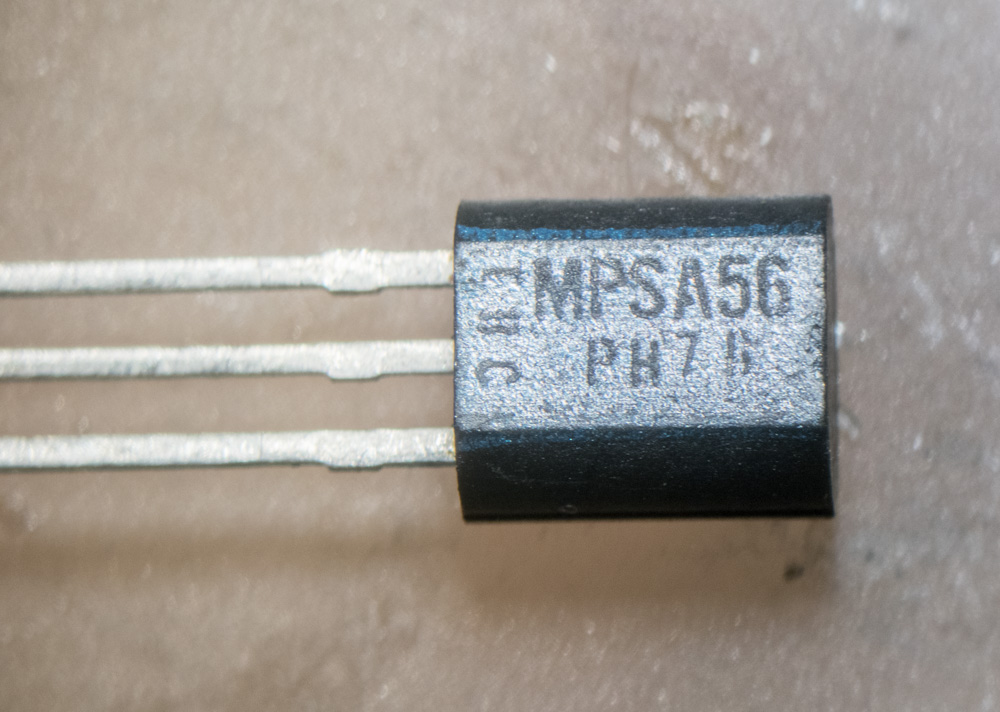

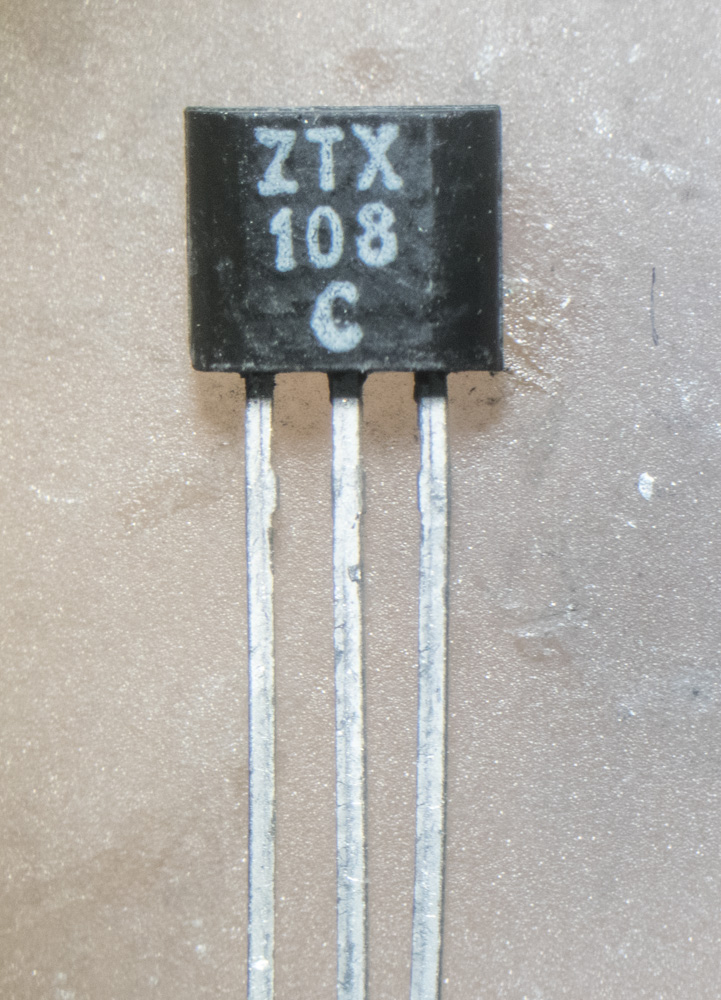

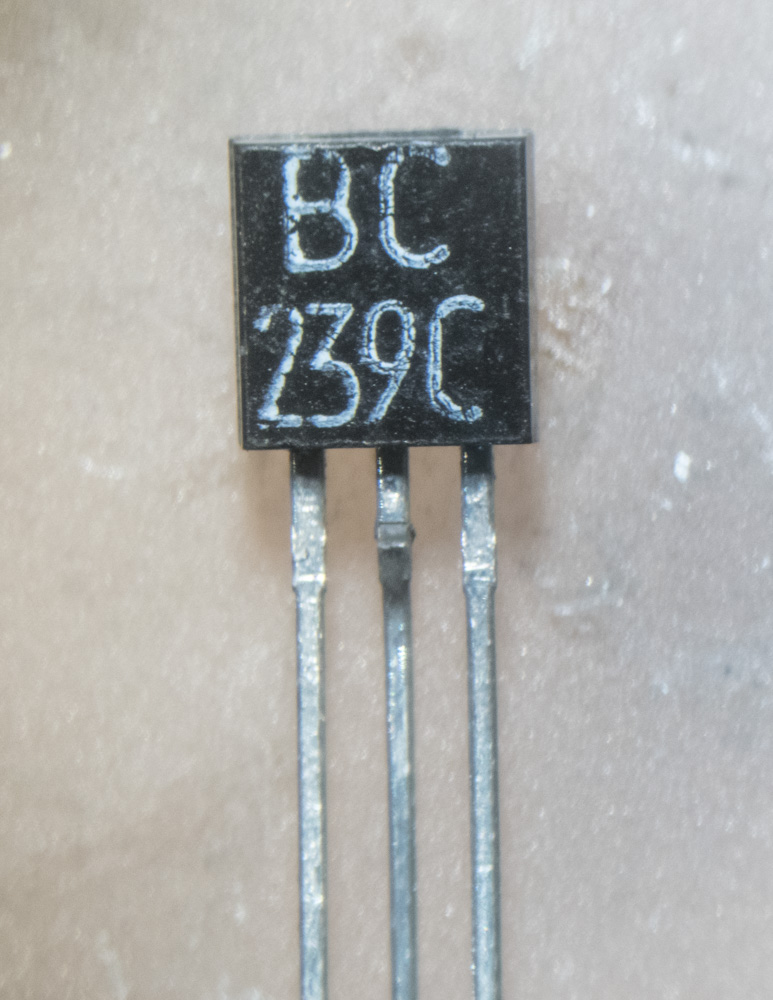

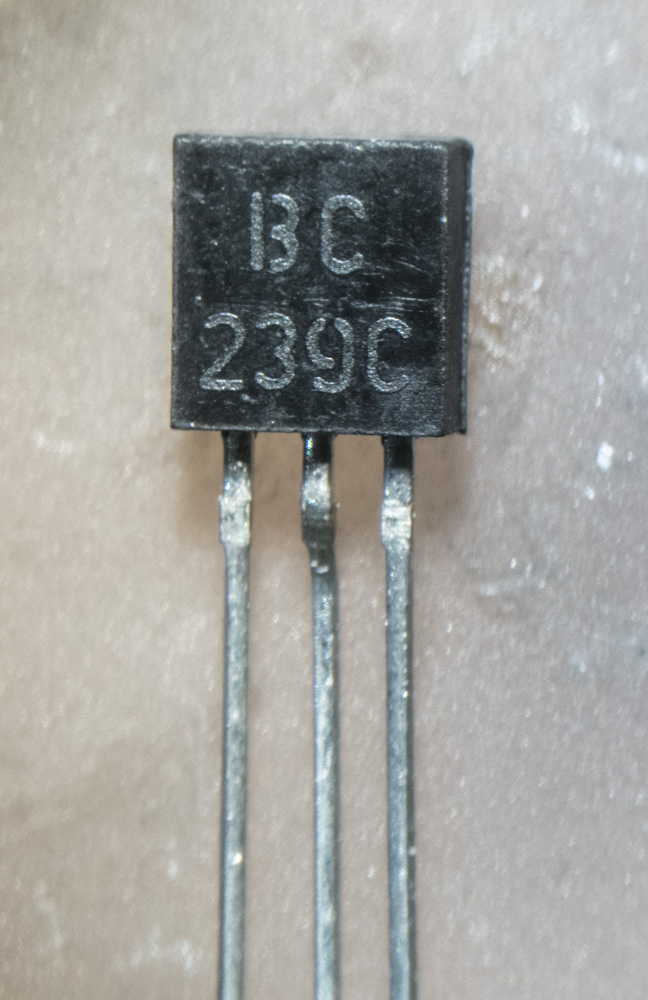

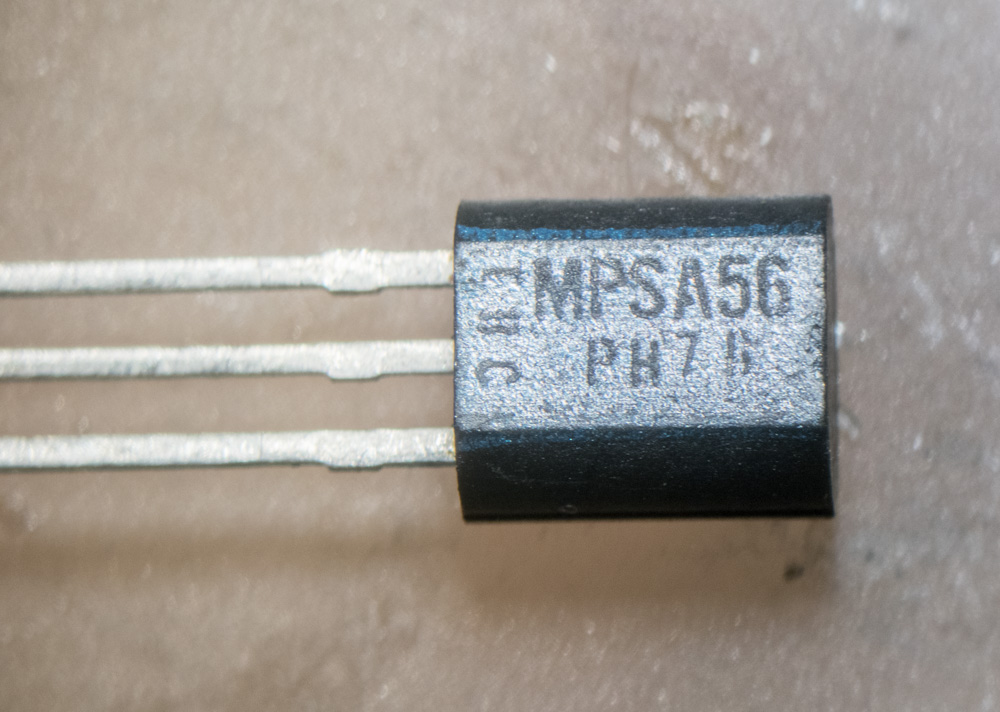

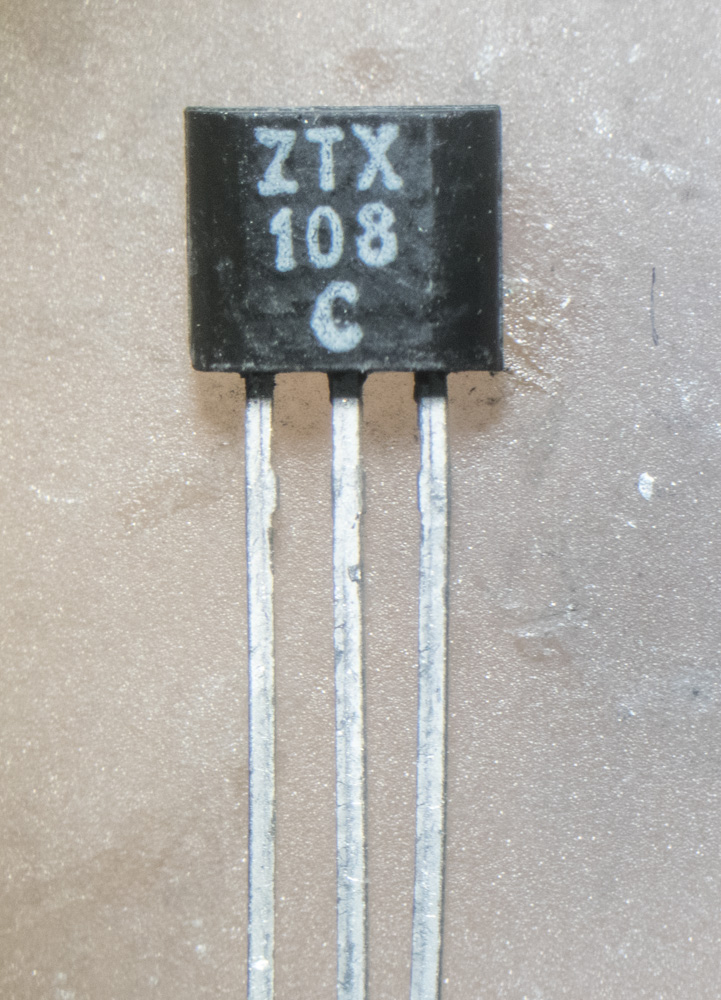

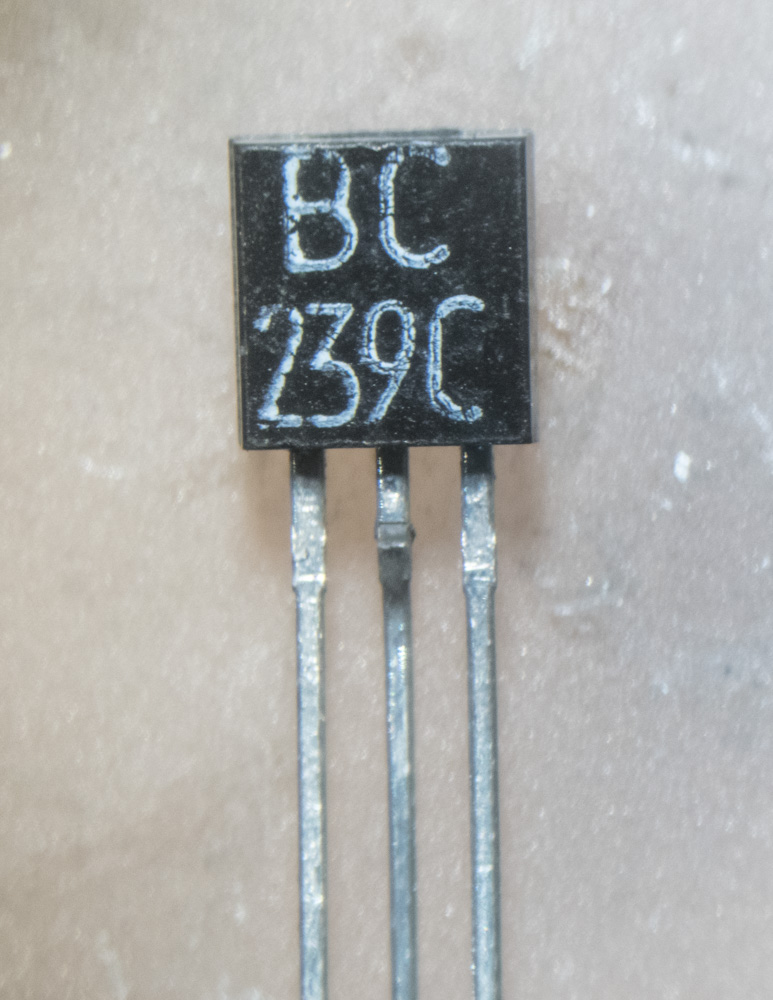

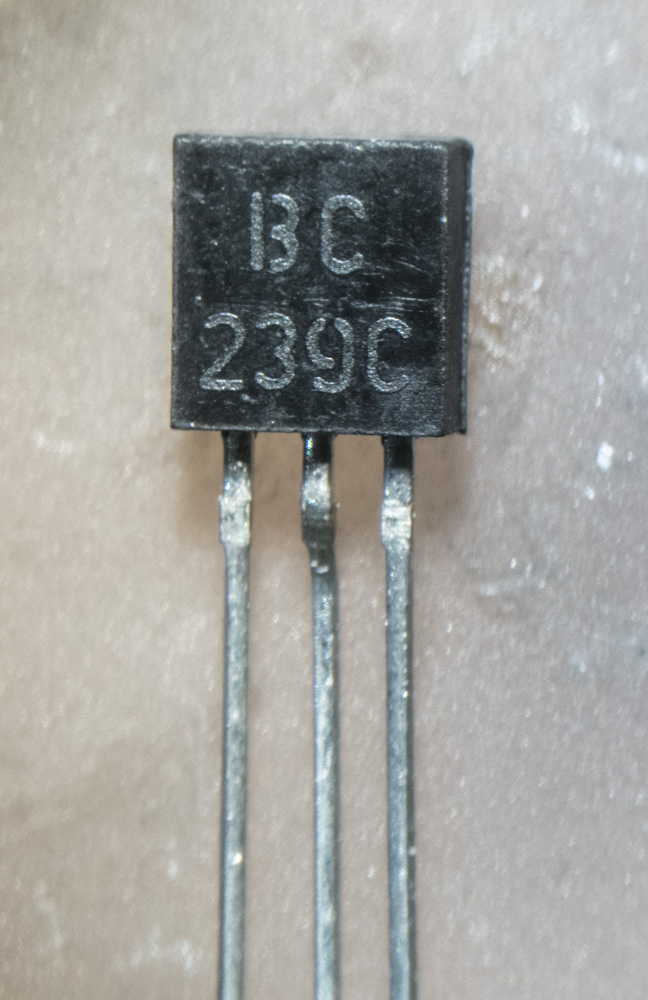

And the small transistors:

The ZTX108C looks old and has the typical flat shape shape, the other TO92s haave the normal shape. The printing "PH" on the MPSA56 hints to Philips, or to made in the Philippines...? The legs of the BC239Cs look fresh and shiny, the other devices have old looking legs. Both types of BC239Cs have the middle leg bent backwards. I was told that one was made by Philips and the other by Siemens. Here are my measurements I took with a small cheap device tester:

BDY58: HFE = 11, VBE = 0.57

BUV20: HFE = 22, VBE = 0.53

MPSA56: HFE = 204, VBE = 0.73

ZTX108C: HFE = 650, VBE = 0.79

BC239C (first picture: Siemens?): HFE = 460, BVE = 0.75

BC239C (second picture: Philips?): HFE = 676, VBE = 0.75

What do you think about my parts?

The BUV20s look a bit too new. The printing on one of them I could remove with aceton (but not with alcohol). It seems there are still new old stock ones available, and I will be happy to supply a link, but first I would like to make sure they are genuine. I also got some small signal transistors from the same source and BDY58s. Here some more pictures:

BUV20 and BDY58 opened with my lathe. The printing on the BDY58 cannot be removed with aceton. The BDY58 has 1mm pins (some show faint corrosion) and looks exactly like the ones on these pictures of an old NAP250 I found online:

Here a closeup of the BDY58 I opened:

My BUV20 has 1.48~1.5mm thick pins. I scratched off the white protection from one die with my finger nails:

The die looks a bit damaged because I was not very careful when sratching off the white rubber-like stuff:

And the small transistors:

The ZTX108C looks old and has the typical flat shape shape, the other TO92s haave the normal shape. The printing "PH" on the MPSA56 hints to Philips, or to made in the Philippines...? The legs of the BC239Cs look fresh and shiny, the other devices have old looking legs. Both types of BC239Cs have the middle leg bent backwards. I was told that one was made by Philips and the other by Siemens. Here are my measurements I took with a small cheap device tester:

BDY58: HFE = 11, VBE = 0.57

BUV20: HFE = 22, VBE = 0.53

MPSA56: HFE = 204, VBE = 0.73

ZTX108C: HFE = 650, VBE = 0.79

BC239C (first picture: Siemens?): HFE = 460, BVE = 0.75

BC239C (second picture: Philips?): HFE = 676, VBE = 0.75

What do you think about my parts?

Last edited: