just an idea

pfm Member

Slight update is that I've been able to change my transformer for one with a center tapped 190v-0v-190v secondary. So I think this will give me (190 x 1.414) 269v into the EZ80 rectifier. I'm struggling to figure out what the voltage drop will be, but will soon find out once I've started building it. Assuming my output voltage needs adjusting, would it be best to do this by changing R15?

My other question for now is about grounding. Would it be best to

1. ground everything direct to a bolt though the chassis as a star ground?

2. keep my ground separate to the chassis ground. And have chassis connected to mains earth?

3. Same as above but connect chassis ground to to my separate circuit ground via a resistor?

I've got 3 different books I'm reading alongside this project which suggest each of these, just trying to pick which will be best.

My other question for now is about grounding. Would it be best to

1. ground everything direct to a bolt though the chassis as a star ground?

2. keep my ground separate to the chassis ground. And have chassis connected to mains earth?

3. Same as above but connect chassis ground to to my separate circuit ground via a resistor?

I've got 3 different books I'm reading alongside this project which suggest each of these, just trying to pick which will be best.

53081867529_a23d8b5a3f_o

53081867529_a23d8b5a3f_o IMG_7915-labels

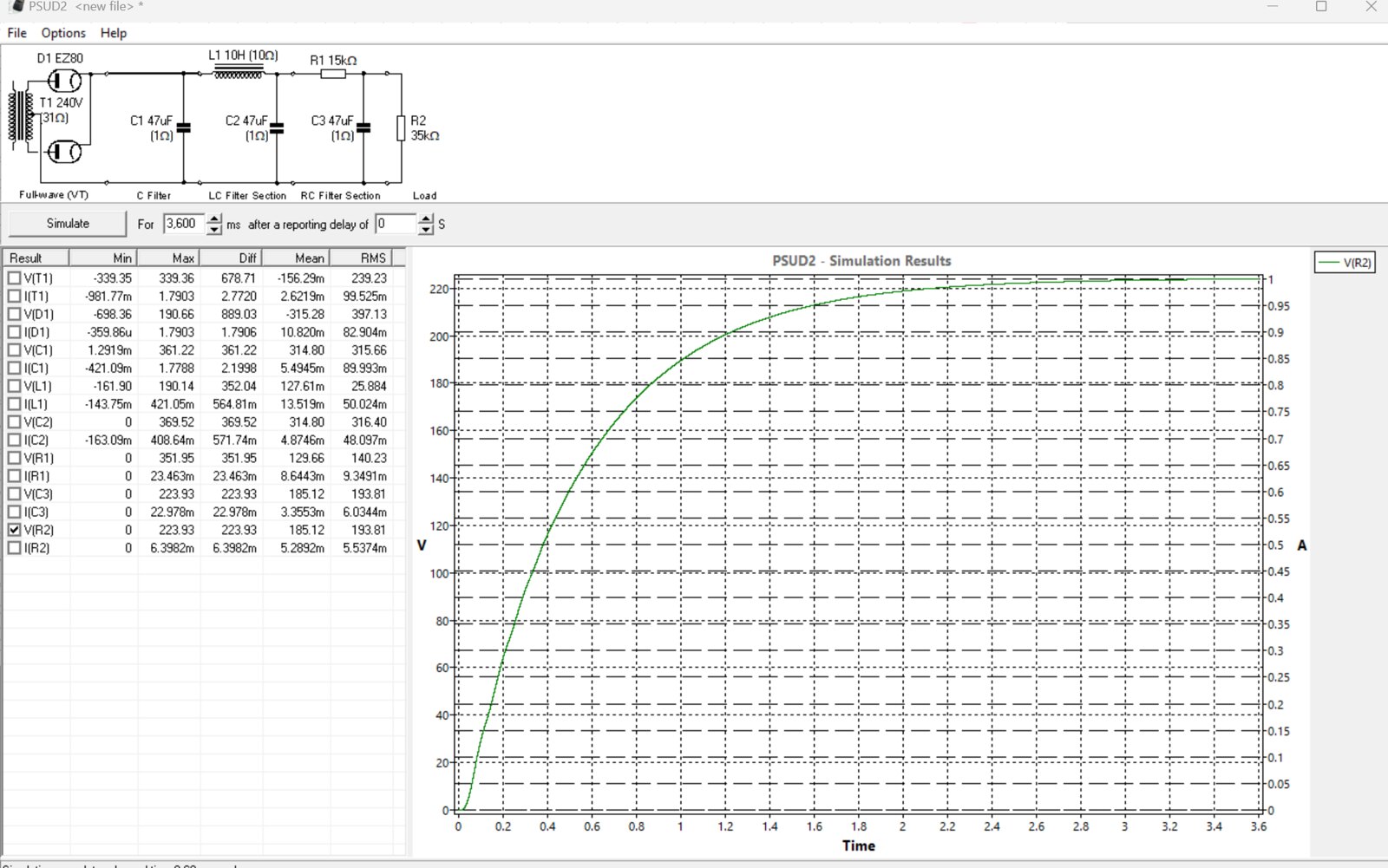

IMG_7915-labels Screenshot 2023-07-30 200452

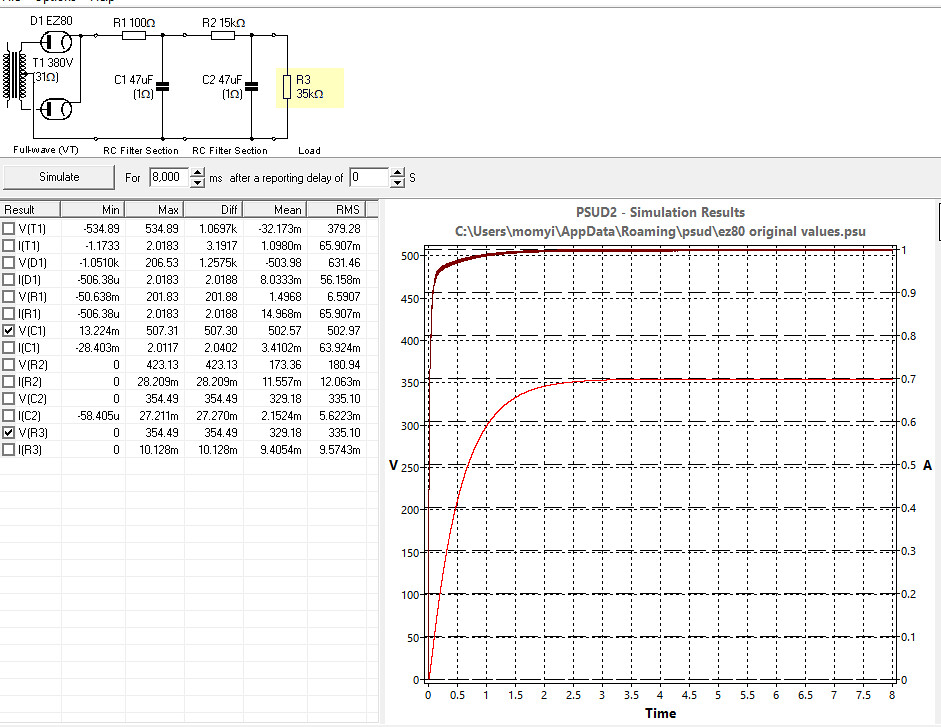

Screenshot 2023-07-30 200452 Screenshot 2023-08-02 190329

Screenshot 2023-08-02 190329 Arkless preamp build

Arkless preamp build Arkless preamp build

Arkless preamp build Arkless preamp build

Arkless preamp build

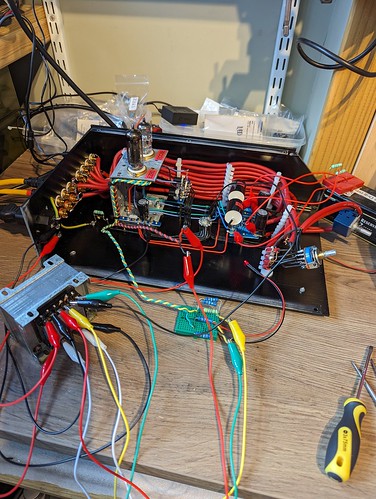

PXL_20230819_145647665

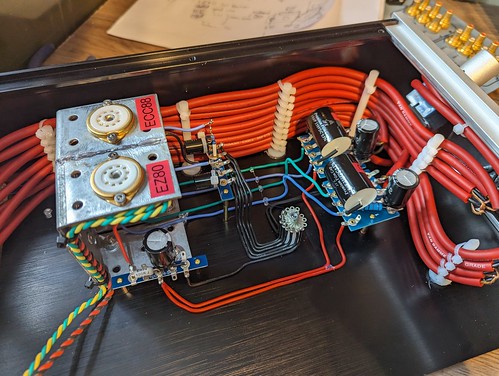

PXL_20230819_145647665 PXL_20230812_122611032

PXL_20230812_122611032 PXL_20230820_101032838

PXL_20230820_101032838 PXL_20230820_101052138

PXL_20230820_101052138 PSU

PSU