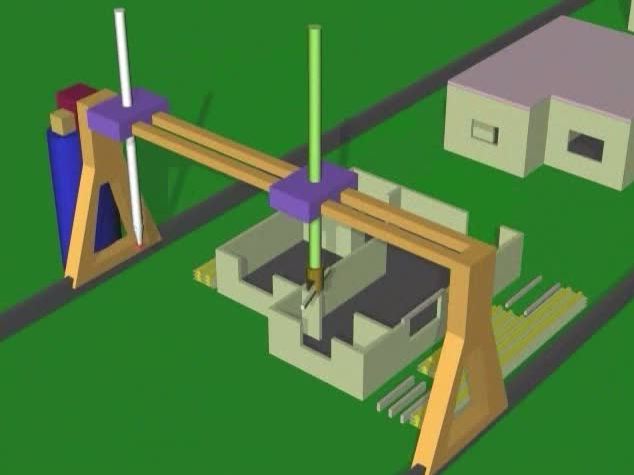

One of the possibilities of learning a software package like SolidWorks 3D is I can routinely draw up and cut new control surfaces for digital instruments out of solid bits of metal, it's pretty standard engineering compared to 3D printing though... we have a few 3D printers but they are very low resolution compared to this:

If you want to make a prototype instrument, one you can physically blow down and play, now the guys at MIT shown you can just print the sucker - providing the printer is up to snuff.

This is a flute, but the end of this video hints at possible new instruments that cannot be made conventionally.

Now is absolutely a great time to be an engineering musician, have an imagination and be able to realise your ideas.

If you want to make a prototype instrument, one you can physically blow down and play, now the guys at MIT shown you can just print the sucker - providing the printer is up to snuff.

This is a flute, but the end of this video hints at possible new instruments that cannot be made conventionally.

Now is absolutely a great time to be an engineering musician, have an imagination and be able to realise your ideas.

Last edited by a moderator: