You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MM cartridge recommendations for original Mission 774 arm

- Thread starter Phil Bishop

- Start date

Phil Bishop

pfm Member

Can you describe the aux counterweight ring so I know what I am looking for?My guess is the threaded headshell is BA - perhaps 8??

You really need extra mass on the counterweight for 7 series AT VM but fine for the 5 series (used both - using auxiliary counterweight ring for the 7 series).

I have this strange silver ring (seen here on the platter) and have been wondering what it's for?

Craig B

Re:trophile

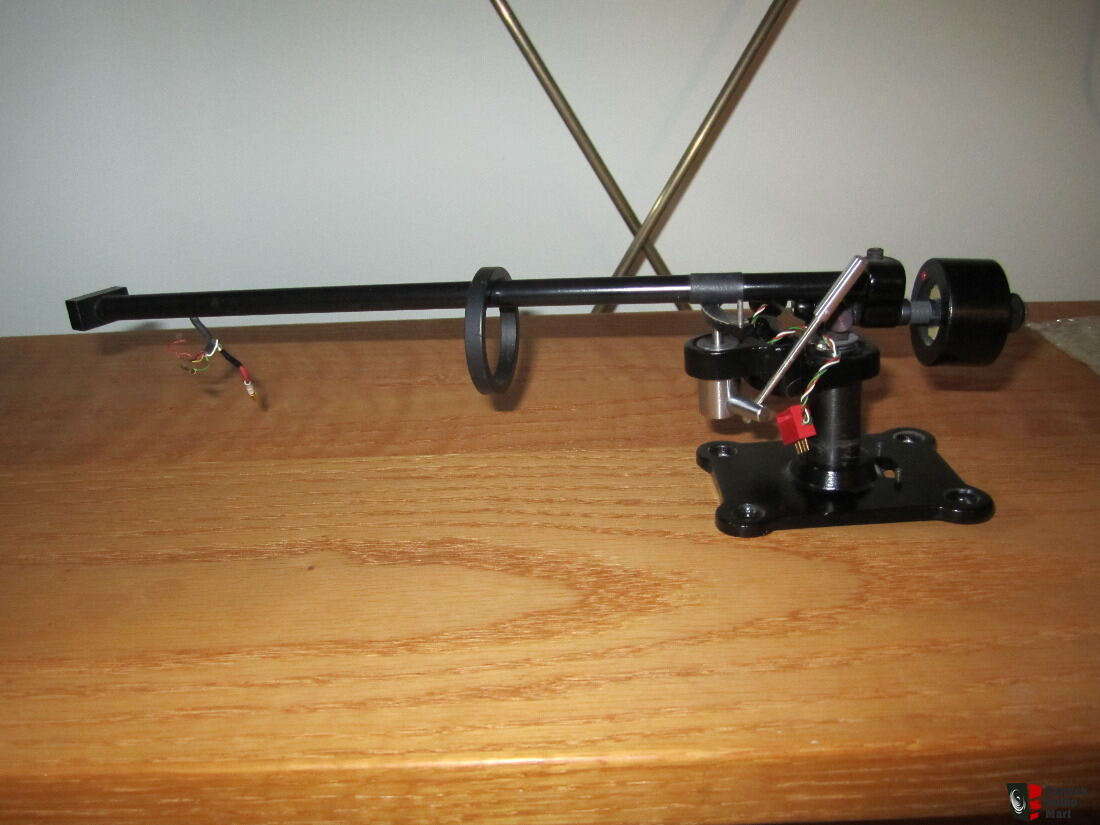

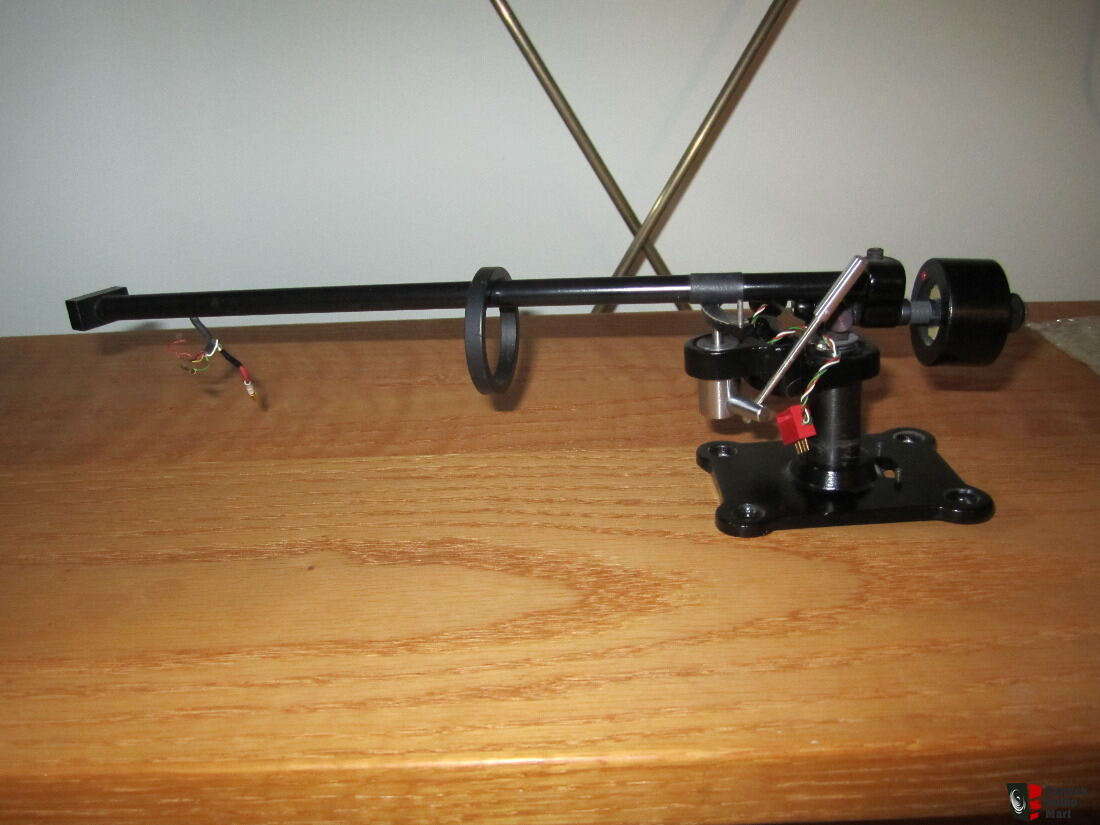

The extra mass ring used to come with the earliest 774 arms. Here is one being used to keep the arm tube down with no cartridge on. In normal use it just fits over the counterweight.

What you have there appears to be a large flat washer, the kind that one might have had with a Grace G-707 tonearm (2nd pic below).

What you have there appears to be a large flat washer, the kind that one might have had with a Grace G-707 tonearm (2nd pic below).

Phil Bishop

pfm Member

Thanks Craig, looks like the additional counterweight is missing with my arm. I’m wondering if the original owner used the washer as a substitute? I know he used a fairly hefty Dynavector MC with the arm so maybe. I may have to adapt something if I need it as I doubt I’d ever find a replacement.

If I remember correctly the “auxiliary mass ring” was an extra that you bought if you needed one. I didn’t get one with my arm when I bought it. It had an internal diameter that matched the external diameter of the main counterweight and so was slid over it and secured in position with a small grub screw. I only ever recall it being available in one size and more than one could be used if necessary. As well as helping match heavier cartridges with the arm it could also be used to get to fine tune the arm by helping getting the counterweight as close to the fulcrum as possible to reduce inertia, this helped with more secure tracking. With some higher compliance cartridges this could be quite dramatic. It may not be a necessity but if you find the counterweight ends up at the rear of the threaded stub it could be worthwhile seeking one out. There was also a heavier mass counterweight that didn’t have the sorbothane isolation.

From your photo it looks like the cartridge mounting block has been drilled through so you could use nylon screws and nuts to reduce the mass at that end.

From your photo it looks like the cartridge mounting block has been drilled through so you could use nylon screws and nuts to reduce the mass at that end.

tenpercenter

Don't ya rile 'em.....

Hi Chaps,

I am just in the process of fitting an original Mission 774 arm to a Systemdek X11900. The arm has been refurbished by The Vinyl Source.

I'm looking for a suitable MM cartridge to fit - I have all the paddles for the arm. I like the current VM offerings from Audio Technica but am not sure about compliance issues?

Any suggestions, recommendations or help appreciated.

A&R Cambridge P77 would be a great match.

Replacement stylus’s still available btw

gerlando

Prog Rocker

Not much difference between VM540ML and VM95ML.Hmmm, maybe my opportunity to try one then? I love the VM95ML

The VM540 series is just a bit better in stereo separation, just a bit.

The stylus should be the same.

Otherwise:

Goldring Elektra?

Grado Green?

Nagaoka MP-110?

Sumiko Pearl?

(depending on your taste).

Phil Bishop

pfm Member

Yep, the only issue is the 95ML would be a pain to fitNot much difference between VM540ML and VM95ML.

The VM540 series is just a bit better in stereo separation, just a bit.

The stylus should be the same.

Otherwise:

Goldring Elektra?

Grado Green?

Nagaoka MP-110?

Sumiko Pearl?

(depending on your taste).

Craig B

Re:trophile

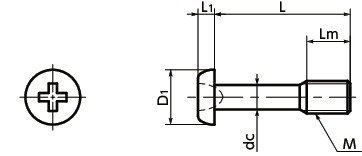

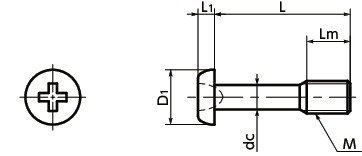

Note that VM95 series accept the same M2.6 size mounting screws as A-Ts bottom mount blind hole headshells (currently AT-LT13A and AT-MG10).

Trouble is, A-T have rationalized their phono cartridge installation hardware down to 8mm x 2, 10mm x 2, plus plastic washer x 2.

Common M2.5 screws are unlikely to fit, however, should one have trouble finding M2.6 that are long enough, a suitable length M2.5 captive screw may be persuaded to pass through from below (with M2.5 nuts atop).

EDIT: These M2.6 look like they might do the 'top down' job...

https://hobbyking.com/en_us/metal-round-head-machine-hex-screw-m2-6x20-10pcs-set.html?___store=en_us

Trouble is, A-T have rationalized their phono cartridge installation hardware down to 8mm x 2, 10mm x 2, plus plastic washer x 2.

Common M2.5 screws are unlikely to fit, however, should one have trouble finding M2.6 that are long enough, a suitable length M2.5 captive screw may be persuaded to pass through from below (with M2.5 nuts atop).

EDIT: These M2.6 look like they might do the 'top down' job...

https://hobbyking.com/en_us/metal-round-head-machine-hex-screw-m2-6x20-10pcs-set.html?___store=en_us

Amber Audio

This is the Day

Have they changed the AT-LT13A and AT-MG10 to M2.6 and 2 sets - they used to be 2.5 with several sets of bolts included - I use some MG10 at presentNote that VM95 series accept the same M2.6 size mounting screws as A-Ts bottom mount blind hole headshells (currently AT-LH11H, AT-LH13H, AT-LH15H, AT-LH18H, AT-LT13A, and AT-MG10).

Trouble is, A-T have rationalized their included phono cartridge and headshell installation screw offerings down to 8mm x 2, 10mm x 2, plus plastic washer x 2.

Common M2.5 screws are unlikely to fit.

PS - why would AT change to 2.6?

Craig B

Re:trophile

I believe that they've always been M2.6, Gus, only folk have managed to get M2.5 to hold on. The headshells likely include more that 2 sets of fasteners as well.

I've just now remembered that AT-LH11H through AT-LH18H are not 'blind hole', they have fixed through hole pairs x 2 (now removed from previous post).

I've just now remembered that AT-LH11H through AT-LH18H are not 'blind hole', they have fixed through hole pairs x 2 (now removed from previous post).

Phil Bishop

pfm Member

Got into trouble trying a VM series bolt in headshell - it seemed to get stuck.Why is that..?

Your headshell is already drilled through, so you just need screws with a thread fitting the AT95

& long enough to go through the whole head + at least ~2/3 into the thread of the AT ?

Phil Bishop

pfm Member

Up and running, sounding excellent even with a humble OM10 but with a low level hum issue - always feckin' hum!

torstoi

pfm Member

Have you got a dedicated earth connection to the headshell somewhere ?

Is the hum the same on both channels ?

You could try pulling off the white and blue cartridge tags and just listen with the green & red connected.

If the hum is there, try the same the other way round, play with only white and blue connected.

If both channels have the same hum problem, it's likely a generic problem,

if it only occurrs on 1 channel, it might be a (light)short somewhere,,,damaged inner cable

or the cables are not isolated as good as the should be somewhere.

Also look those tags cannot touch each other in any way, cannot see it clearly but looks rather tight.

And check the earth cable from the deck is in good condition and screwed on making good contact.

As a short test you could also screw a thin loose wire (~1,5m long)under the nut of your headshell

while the arm is in parked position.

And screw the other end to the earth point of your pre-amp.

Leave it in parked position & turn up the volume if it still hums.

If not the missing earth in the arm is the issue..

Is the hum the same on both channels ?

You could try pulling off the white and blue cartridge tags and just listen with the green & red connected.

If the hum is there, try the same the other way round, play with only white and blue connected.

If both channels have the same hum problem, it's likely a generic problem,

if it only occurrs on 1 channel, it might be a (light)short somewhere,,,damaged inner cable

or the cables are not isolated as good as the should be somewhere.

Also look those tags cannot touch each other in any way, cannot see it clearly but looks rather tight.

And check the earth cable from the deck is in good condition and screwed on making good contact.

As a short test you could also screw a thin loose wire (~1,5m long)under the nut of your headshell

while the arm is in parked position.

And screw the other end to the earth point of your pre-amp.

Leave it in parked position & turn up the volume if it still hums.

If not the missing earth in the arm is the issue..

Phil Bishop

pfm Member

Thanks for the advice chaps, just playing around I seem to be able to reduce hum with better earthing although I don't have the best wires so I have ordered a dedicated earth cable to earth the deck.

I have also ordered some plastic bolts as the ones I'm using are bog standard stainless steel from Amazon.

I doubt if there are any issues with the arm wiring as it has just been re-wired by a professional

I have also ordered some plastic bolts as the ones I'm using are bog standard stainless steel from Amazon.

I doubt if there are any issues with the arm wiring as it has just been re-wired by a professional

torstoi

pfm Member

Yes I noticed the cartridge tags looked rather like new Cardas stuff and

it generally looked nice quality to me.

I didn't want to hint at any unprofessional acts in any way,

I just stated what I would to if presented with such prob from zero..

Dedicated arm earth it seems to be then..a problem many early Rega arms share as far as I know..

Very nice arm and deck btw.

it generally looked nice quality to me.

I didn't want to hint at any unprofessional acts in any way,

I just stated what I would to if presented with such prob from zero..

Dedicated arm earth it seems to be then..a problem many early Rega arms share as far as I know..

Very nice arm and deck btw.