Sposhal

Torac Audio

So I have been working on the replacement diaphragm for the T50rp headphone as that would allow me to get a full headphone out sooner, that way more people will be able to hear my sound.

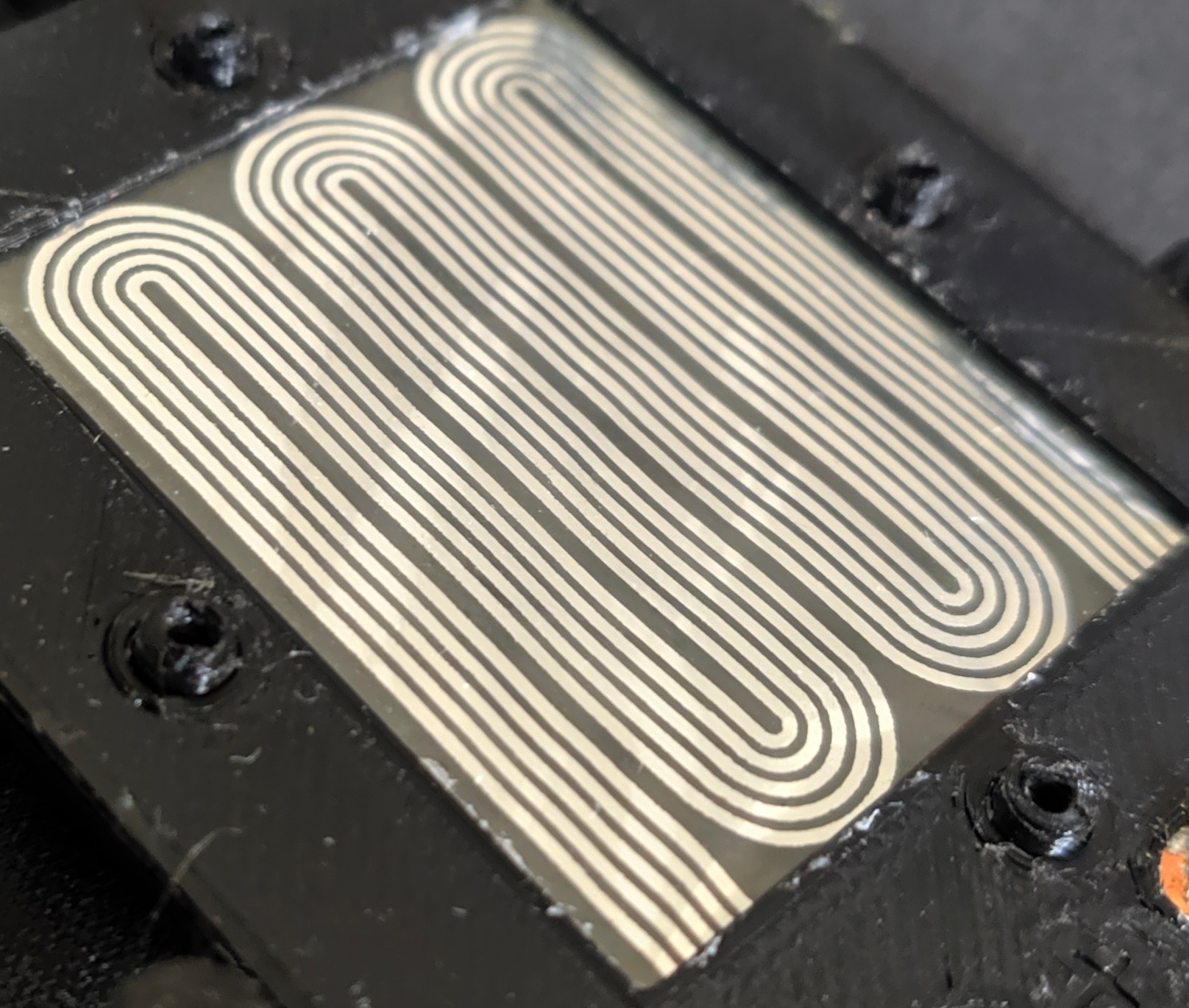

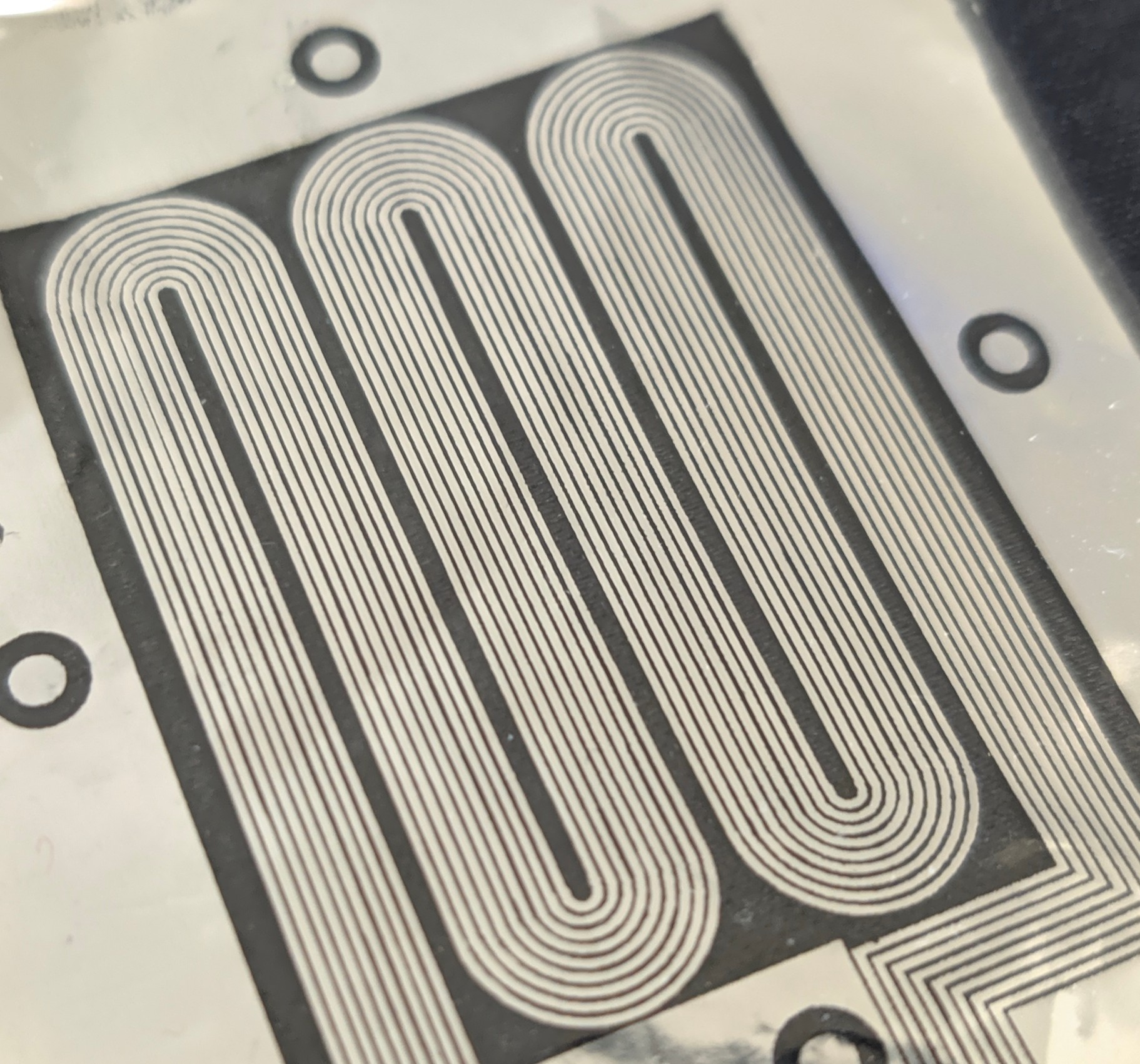

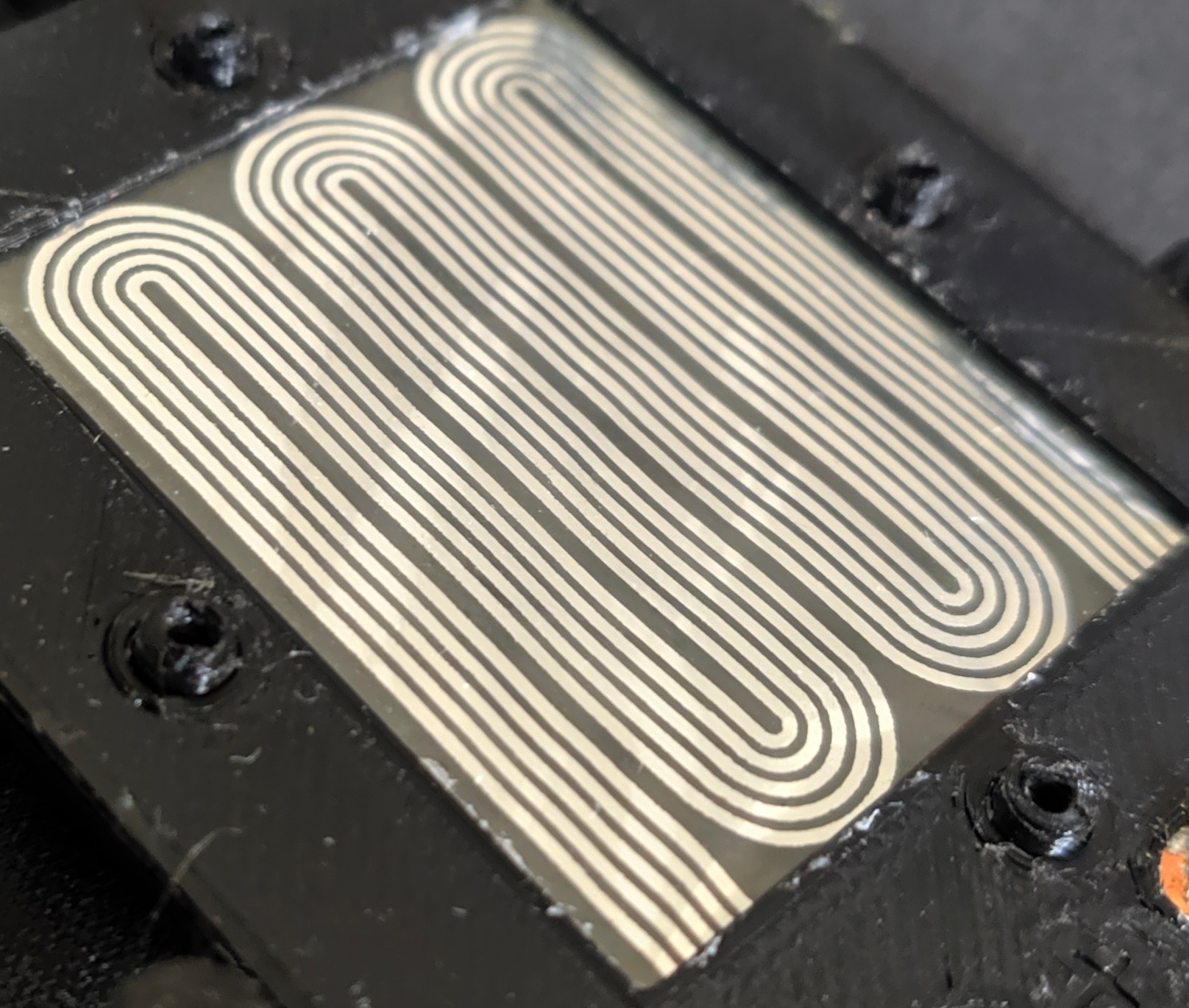

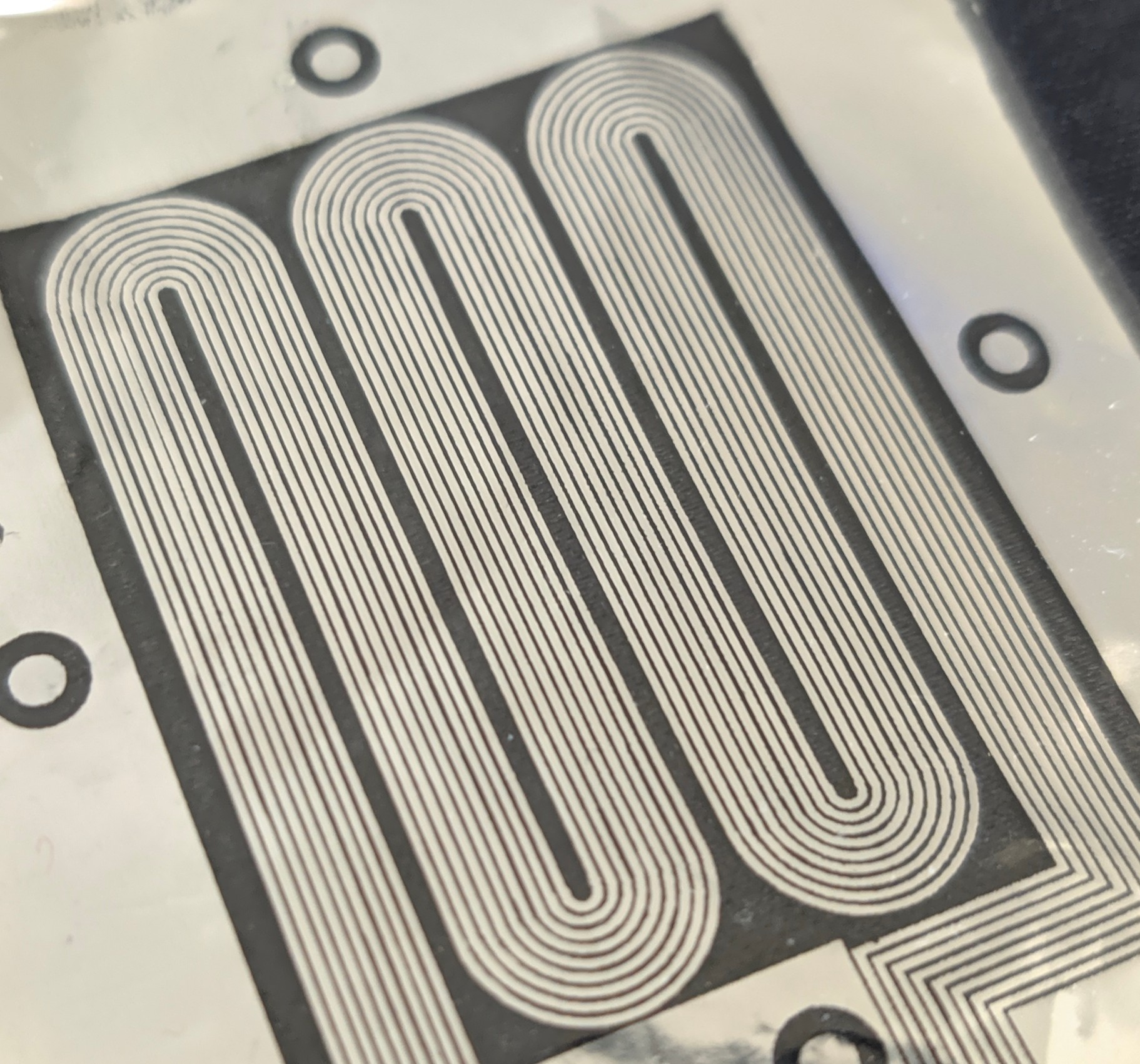

I have done some work on the trace as you can see below:

Old: 16 Ohms

New: 36 Ohms

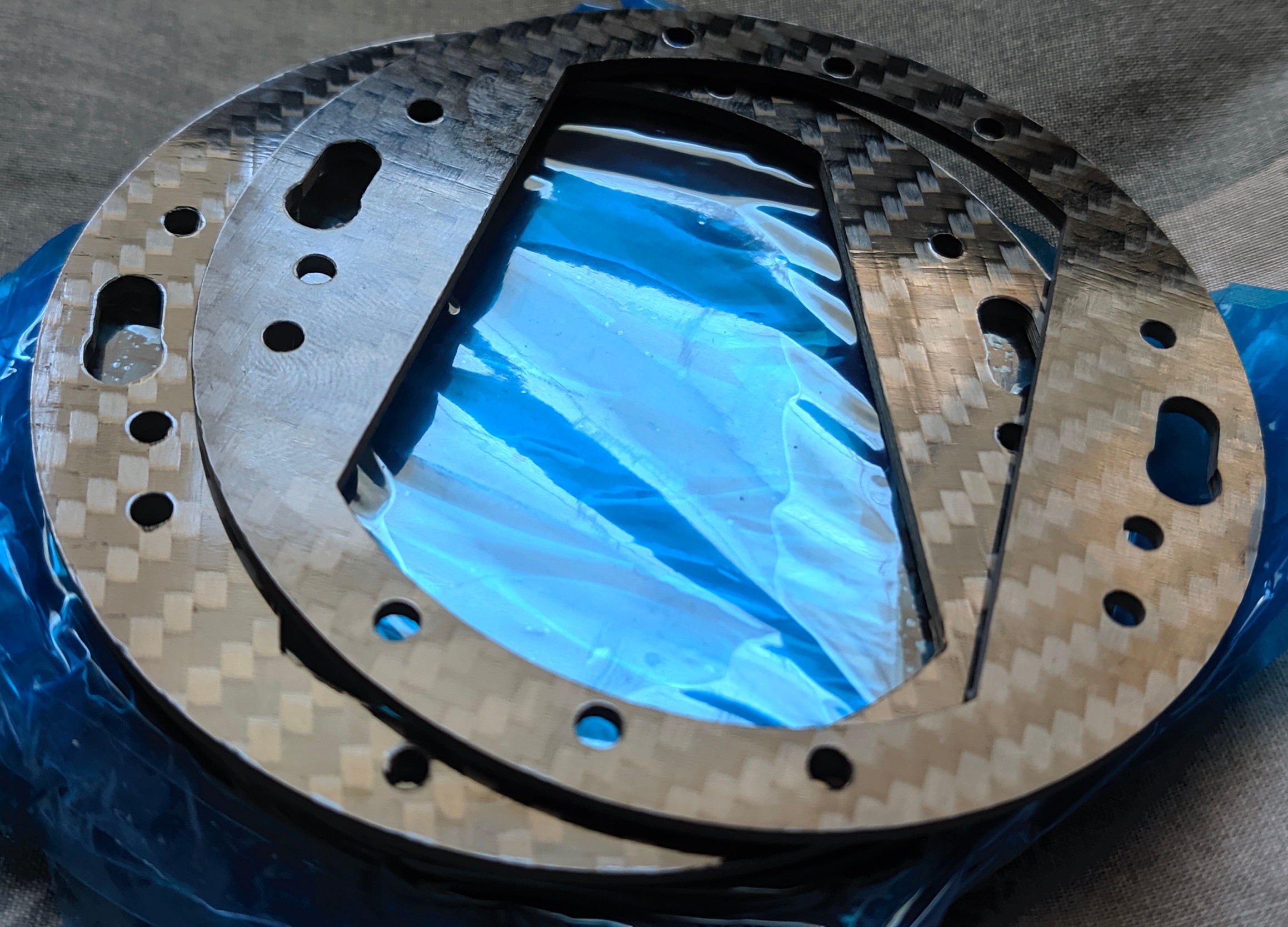

I also used my new tension jig this time to apply a really low tension which has fixed the issues I had with this driver before.

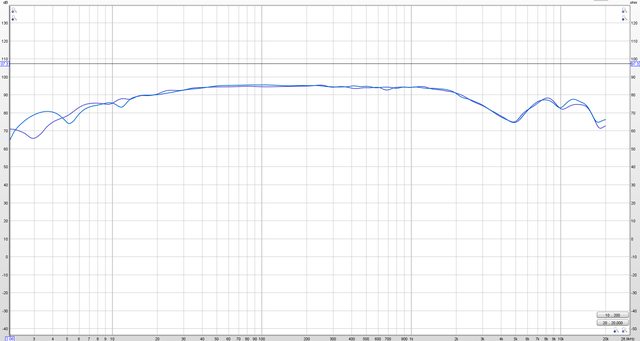

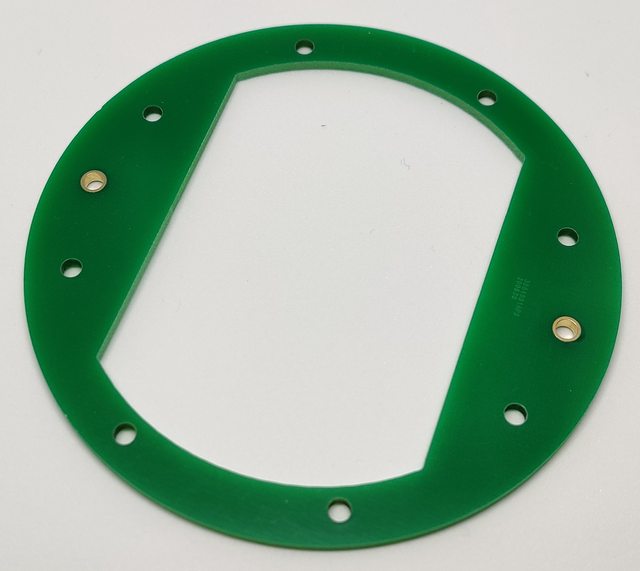

I have spent all of today trying different damping materials and I think I have it close to what I like but would need a bit more time to get the finer things correct. I also would like to design some decals for the headphone cups and a headstrap to improve comfort.

I have done some work on the trace as you can see below:

Old: 16 Ohms

New: 36 Ohms

I also used my new tension jig this time to apply a really low tension which has fixed the issues I had with this driver before.

I have spent all of today trying different damping materials and I think I have it close to what I like but would need a bit more time to get the finer things correct. I also would like to design some decals for the headphone cups and a headstrap to improve comfort.