Hi daveofbradford,

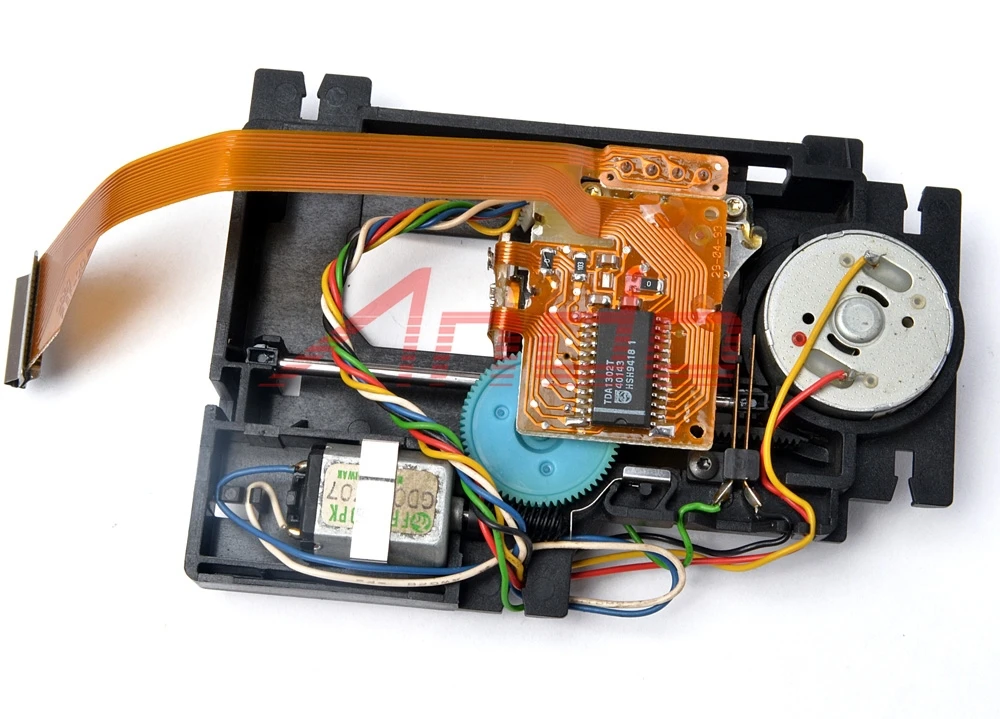

Had a good google round and seem to be able to confirm the cdm12.4 in the stage players, but if memory serves its also a linear mech in the drive, not a swinging arm like the cdm9.

I need to take a peek I think!

Seen a stage 2 on e-bay and was going to buy for:

a) spares for my drive 3, and:

b) use the case-work with a new front-plate to install my NCC200s as I can't find a decent looking case at reasonable money and these boards were completed btwn Xmas / new year. Was going to make one from 10mm marine ply but too much hassle to cut accurately and I don't have a circular-saw bench. The only cases I have seen that I like are to A-tech round-fronted ones- tooooo expensive.

Thanks,

AP