Pete MB&D

Pete Maddex, the one and only!

Hi Chaps

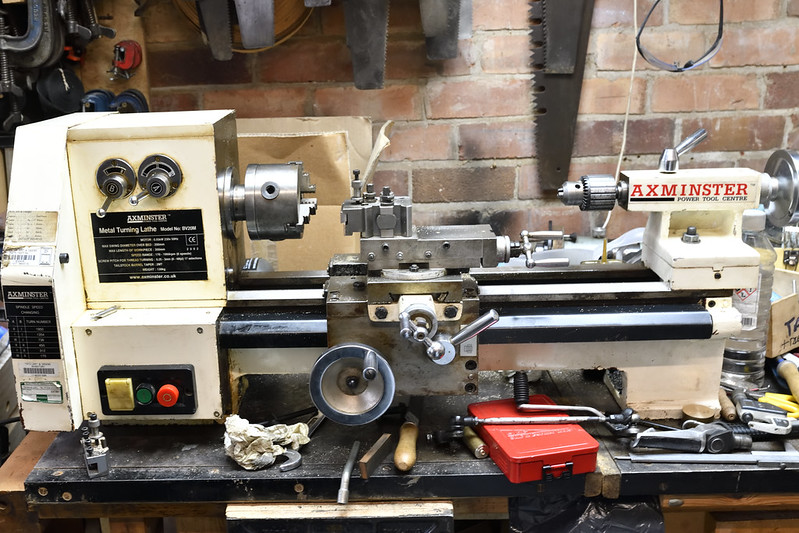

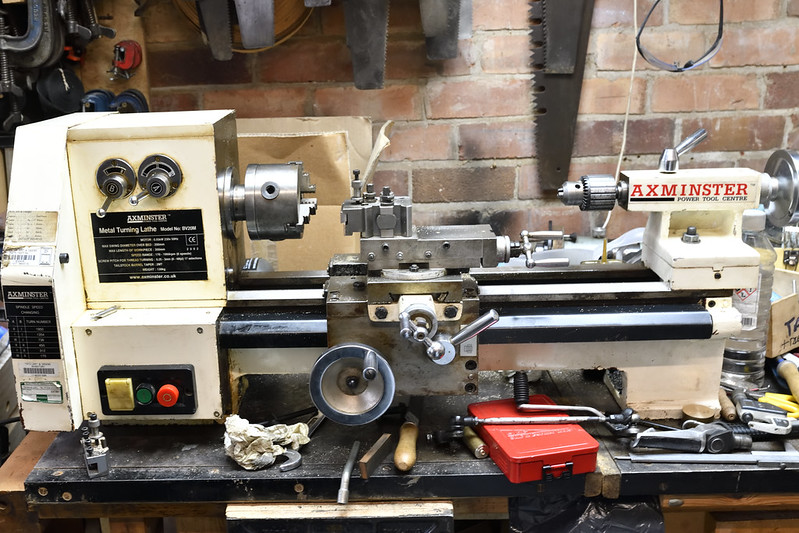

I finally decided to get the lathe out of the shed clean it up and make some new knobs for my spokeshave.

I was given this lathe, its missing its change gears unfortunately.

It needed a start capacitor to get it going and a good clean up.

Axminister BV20M by Pete Maddex, on Flickr

Axminister BV20M by Pete Maddex, on Flickr

This is the spokeshave with some Ebay knobs.

Rosewood spokeshave by Pete Maddex, on Flickr

Rosewood spokeshave by Pete Maddex, on Flickr

And here it is with the ones I made.

Rosewood spokeshave by Pete Maddex, on Flickr

Rosewood spokeshave by Pete Maddex, on Flickr

Did a bit of messing round making shavings, facing off bits of bar modifying the vacuum take-off adaptors for my carburettor balancer etc.

Pete

I finally decided to get the lathe out of the shed clean it up and make some new knobs for my spokeshave.

I was given this lathe, its missing its change gears unfortunately.

It needed a start capacitor to get it going and a good clean up.

Axminister BV20M by Pete Maddex, on Flickr

Axminister BV20M by Pete Maddex, on FlickrThis is the spokeshave with some Ebay knobs.

Rosewood spokeshave by Pete Maddex, on Flickr

Rosewood spokeshave by Pete Maddex, on FlickrAnd here it is with the ones I made.

Rosewood spokeshave by Pete Maddex, on Flickr

Rosewood spokeshave by Pete Maddex, on FlickrDid a bit of messing round making shavings, facing off bits of bar modifying the vacuum take-off adaptors for my carburettor balancer etc.

Pete