stackowax

pfm Member

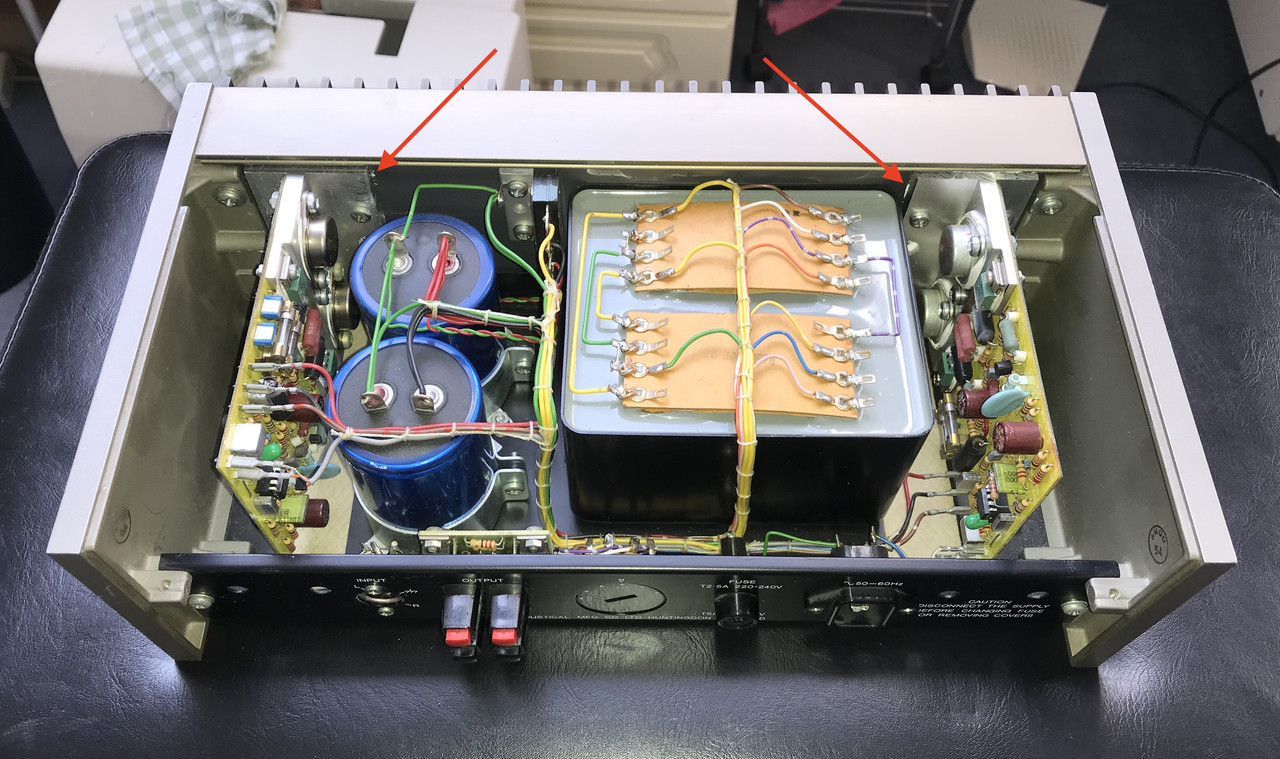

I'm trying to find some thermal paste locally (I'm in the US) to put between the case and the heat sinks on the amp and regulator modules on my NAP250. Looks like the only thing available is stuff intended for use on CPUs, for example this. Is this okay to use or should order something different on-line?