fraserking

Trade: custom speaker cabinets

After months on planning I have finally made some progress with my DU316 drivers.

I bought the drivers off ebay a couple of years ago with no cones and had some fitted by Nick at Lockwood. They sounded so much better than my hard edged 12"HPDs in the bass that it prompted me to recone my HPDs with standard foamed cones (pictured in cherry cabs below) which Nick supplied me and I fitted ( much hand holding from Frank) this had the added benefit that I got lovely new looking blue tinted cones on those too.

Here are my current cabinets with 315s :

and the DU316/K3128 drivers I got from ebay:

prompting me to get these:

I had always planned to build some Legacy/HPD style cabs for the spare K/DU drivers at some stage and when a local friend expressed an interest in buying some cabs for K drivers if i made some up I decided to make a start.I learned a lot building some System 8 clones a couple of years back and have used a brace system based on that pro range for the last couple of Tannoy builds - my SRM10b clones (another thread coming) look like standard cabs from the outside but have the System style bracing and are the deadest cabs you`ll ever tap your knuckles on!

My local timber supplier had a sheet of Teak veneered MDF left over from an overorder and let me have it cheap and thats what kick started this build.

Here`s a top panel showing the routed slots for the front and rear panels:

I edged them up with iron on Teak edging before cutting the 45 mitres,

theyre sitting on the matrix bracing:

Just the cheapest 18mm ply my supplier had:

Front baffle is 19mm MDF with 12mm birch glued/clamped behind

Rear is 18 glued to 9mm birch - just cos thats what i had spare off cuts from my latest kitchen build.

I ordered some lovely looking ports from Hifi collective- 100mm flared at front , but they looked so enormous when i offered them up I had to look again.

They looked somehow wrong being bigger than the DC dustcap. Alas i couldnt find anything like the ports I used on my other 100L cabs in the previous pic anywhere on the web so decided to have a go making my own in a size that looked better suited to baffle/driver.

Very chuffed with the fit of these, they just need spraying up to finish .I may yet try making some in Iroko or Teak as an alternative now that I`ve taken the trouble to make a jig for the job!

and with the front edge rounded over:

and flush fitted to the baffle:

dry run:

to fix brace to cabinet walls , same sort of stuff Tannoy used in System 15 etc,strong but flexible :

First cab glued:

and then Osmo oiled - first with Raw then with standard Polyx hard wax oil matt- all the beauty of Danish but with added protection of the hard wax. The Teak veneer is like Rizzla paper!

Very pleased with colour and finish of the Teak. Better than I had hoped.Just the badges to sort to finish with Legacy/HPD style rounded corner grilles. The engravers have had 3 goes at matching the original logo size on the badges - this is the closest so far but he reckons he can get it spot on.He`s only working from a photo i sent him!

So just terminal and crossover panels to cut on the rear panel and the ports to spray and the teak plinths to fit to the bases. I`m gonna make a panel big enough for the terminal and the crossover - removable so that alternative crossovers/connections can be fitted without leaving a hole.

I`m not quite at the shoot out stage with the HPDs yet but i did line 1 cab with foam and did a temp screw on of the back panel and fired 1 cab up - very nice with clean, even bass down to 33 HZ just as i get with the other 105L cabs I have fitted with the HPDs. This is the biggest size of cab I can fit in my living room but frankly I dont think I need any more bass than this gives.Its proper live music bass.

I will update with more pics over the coming weeks. Still got the crossovers to deal with...

If my friend keeps these cabs I`ll be making another pair for sure as i love the 70`s look of these.

I bought the drivers off ebay a couple of years ago with no cones and had some fitted by Nick at Lockwood. They sounded so much better than my hard edged 12"HPDs in the bass that it prompted me to recone my HPDs with standard foamed cones (pictured in cherry cabs below) which Nick supplied me and I fitted ( much hand holding from Frank) this had the added benefit that I got lovely new looking blue tinted cones on those too.

Here are my current cabinets with 315s :

and the DU316/K3128 drivers I got from ebay:

prompting me to get these:

I had always planned to build some Legacy/HPD style cabs for the spare K/DU drivers at some stage and when a local friend expressed an interest in buying some cabs for K drivers if i made some up I decided to make a start.I learned a lot building some System 8 clones a couple of years back and have used a brace system based on that pro range for the last couple of Tannoy builds - my SRM10b clones (another thread coming) look like standard cabs from the outside but have the System style bracing and are the deadest cabs you`ll ever tap your knuckles on!

My local timber supplier had a sheet of Teak veneered MDF left over from an overorder and let me have it cheap and thats what kick started this build.

Here`s a top panel showing the routed slots for the front and rear panels:

I edged them up with iron on Teak edging before cutting the 45 mitres,

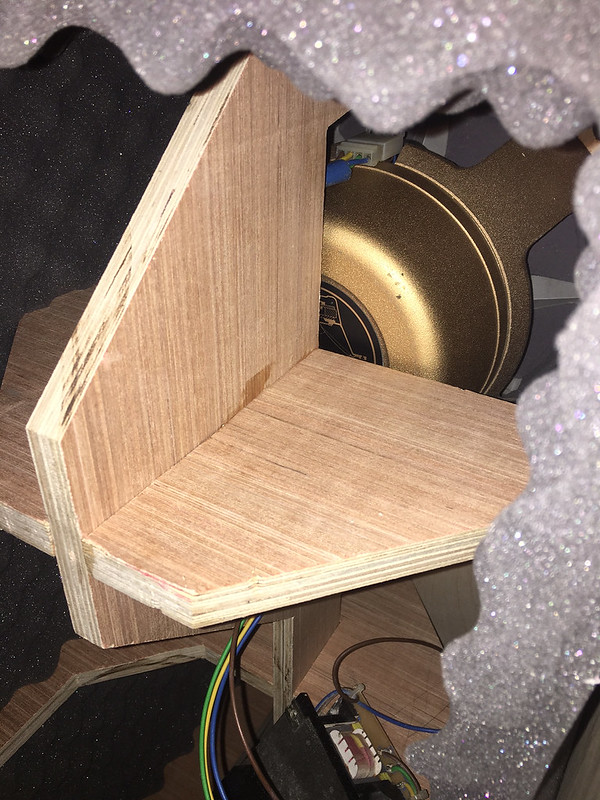

theyre sitting on the matrix bracing:

Just the cheapest 18mm ply my supplier had:

Front baffle is 19mm MDF with 12mm birch glued/clamped behind

Rear is 18 glued to 9mm birch - just cos thats what i had spare off cuts from my latest kitchen build.

I ordered some lovely looking ports from Hifi collective- 100mm flared at front , but they looked so enormous when i offered them up I had to look again.

They looked somehow wrong being bigger than the DC dustcap. Alas i couldnt find anything like the ports I used on my other 100L cabs in the previous pic anywhere on the web so decided to have a go making my own in a size that looked better suited to baffle/driver.

Very chuffed with the fit of these, they just need spraying up to finish .I may yet try making some in Iroko or Teak as an alternative now that I`ve taken the trouble to make a jig for the job!

and with the front edge rounded over:

and flush fitted to the baffle:

dry run:

to fix brace to cabinet walls , same sort of stuff Tannoy used in System 15 etc,strong but flexible :

First cab glued:

and then Osmo oiled - first with Raw then with standard Polyx hard wax oil matt- all the beauty of Danish but with added protection of the hard wax. The Teak veneer is like Rizzla paper!

Very pleased with colour and finish of the Teak. Better than I had hoped.Just the badges to sort to finish with Legacy/HPD style rounded corner grilles. The engravers have had 3 goes at matching the original logo size on the badges - this is the closest so far but he reckons he can get it spot on.He`s only working from a photo i sent him!

So just terminal and crossover panels to cut on the rear panel and the ports to spray and the teak plinths to fit to the bases. I`m gonna make a panel big enough for the terminal and the crossover - removable so that alternative crossovers/connections can be fitted without leaving a hole.

I`m not quite at the shoot out stage with the HPDs yet but i did line 1 cab with foam and did a temp screw on of the back panel and fired 1 cab up - very nice with clean, even bass down to 33 HZ just as i get with the other 105L cabs I have fitted with the HPDs. This is the biggest size of cab I can fit in my living room but frankly I dont think I need any more bass than this gives.Its proper live music bass.

I will update with more pics over the coming weeks. Still got the crossovers to deal with...

If my friend keeps these cabs I`ll be making another pair for sure as i love the 70`s look of these.