You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SBLs

- Thread starter robbyd

- Start date

DoctorRad

pfm Member

Great thread, will definitely be following your progress! I have a pair of SBLs which I picked up last summer which I am planning to take active with a pair of Hypex FA122 units for maximum crossover flexibility. They may not end up as 'proper' SBLs, but I have hopes of something exciting coming out of the bodging…

DoctorRad

pfm Member

They're not being exceptionally well driven at the moment, and they need re-sealing… but there's a lot to like there, even if the presentation can be a little sterile… Perhaps the difference between genuine 'high fidelity' and something which 'sounds nice'? Perhaps they're being constrained by the standard passive crossovers, which is why for £6-700 for a pair and a box, a brace of FA122s seems like a complete no-brainer for experimentation purposes…What do you think of them in their current guise?

In the meantime, when I get my new place, I'll have them on the end of a pair of RB-850s and a Meridian 208 - also acting as preamp. Should be fun…

Thanks for that - first time I've heard them called sterile! I was planning on wiring them up this weekend for a proper listen but the thought of doing all that work only to have to take them apart again to continue working on them doesn't appeal at all...

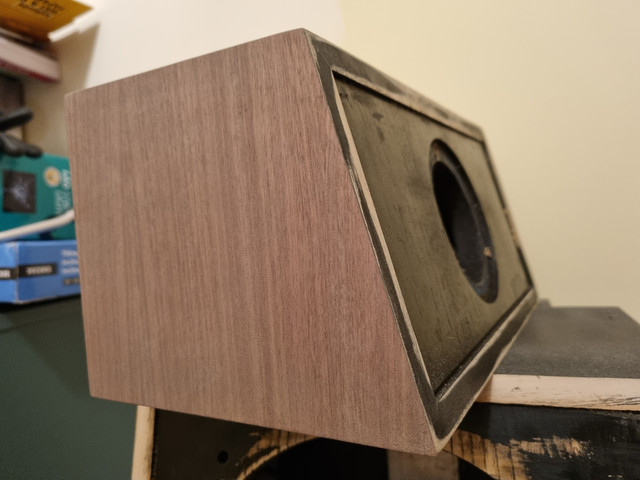

Veneer arrived today.. I may have over ordered slightly but it does look like a lovely batch

I'm thinking the bit nearer the bottom with the three repeated patterns should be the front 'face' of the lower cabinet, and the rest would follow naturally from there

Veneer arrived today.. I may have over ordered slightly but it does look like a lovely batch

I'm thinking the bit nearer the bottom with the three repeated patterns should be the front 'face' of the lower cabinet, and the rest would follow naturally from there

I love walnut  This is enough to do one speaker:

This is enough to do one speaker:

With the small surface areas the SBL cabinet is a great candidate for re-veneering. I had toyed with the idea of veneering the rear surfaces, along with those between the units. I have enough spare veneer to do this but I quite like the contrast between the black surfaces and the wood. It also introduces another edge to go wrong and i'm not exactly a pro woodworker so want to keep it as straightforward as possible. This is also the reason for using PSA veneer...

With the small surface areas the SBL cabinet is a great candidate for re-veneering. I had toyed with the idea of veneering the rear surfaces, along with those between the units. I have enough spare veneer to do this but I quite like the contrast between the black surfaces and the wood. It also introduces another edge to go wrong and i'm not exactly a pro woodworker so want to keep it as straightforward as possible. This is also the reason for using PSA veneer...

Quite a productive lunch break today. Now that i know I'll be veneering them the sanding is much quicker - the intention being to create a flat surface rather than remove all black paint. The most time consuming bit is removing the sticky mess left behind by the velcro. It's no use trying to sand it, it just clogs up the sander. I've been using a toffee wheel on the drill to blast it off but it takes absolutely ages.

The metalwork was quite a mess:

Slightly better:

The metalwork was quite a mess:

Slightly better:

Powder coating would be ideal but expensive and may take a few weeks. Alternatively, the Motip brand of rattlecan primers and finishes (available via Amazon and other retailers) are a good match for, for example, Target racks and stands, and have proven resilient in outdoor applications such as my old motorcycles.

Some of those screws and nuits have seen better days. Depending on how "original" you want to be, stainless or adonised black alternatives might be better. Boltbase are a quick, economic and relaiable postal supplier, either direct or again through Amazon.

This is a brilliant thread.

Some of those screws and nuits have seen better days. Depending on how "original" you want to be, stainless or adonised black alternatives might be better. Boltbase are a quick, economic and relaiable postal supplier, either direct or again through Amazon.

This is a brilliant thread.

stephen bennett

Mr Enigma

This is a brilliant thread.

Apart from the ones on the screws.

Agreed. This is a great project. Pity we can't all come over for a listen.

Stephen

Thanks gents. Glad i'm not just speaking to myself

Powder-coating would be great but not sure it's worth the money if I can get a reasonable finish myself, and I've spent all my speaker funds on fancy crossover components! I don't have any contacts in that industry up here unfortunately.

I've bought a little tin of a paint by Rustins called matt black, for use on iron & wood. The reason I bought it was off the back of an amazon review for the 250ml tub here Rustins BLAM250 250ml Paint - Matt Black : Amazon.co.uk: DIY & Tools where people have uploaded some photos, and it looks great... there's a fireplace one in particular where the finish is exactly what I'd like to achieve on the baffles and metalwork. I'll sample it on the smaller flat bits of metal today to see how it turns out.

Powder-coating would be great but not sure it's worth the money if I can get a reasonable finish myself, and I've spent all my speaker funds on fancy crossover components! I don't have any contacts in that industry up here unfortunately.

I've bought a little tin of a paint by Rustins called matt black, for use on iron & wood. The reason I bought it was off the back of an amazon review for the 250ml tub here Rustins BLAM250 250ml Paint - Matt Black : Amazon.co.uk: DIY & Tools where people have uploaded some photos, and it looks great... there's a fireplace one in particular where the finish is exactly what I'd like to achieve on the baffles and metalwork. I'll sample it on the smaller flat bits of metal today to see how it turns out.

This site contains affiliate links for which pink fish media may be compensated.