Tony L

Administrator

I don’t think I’ve ever started a thread in this room, so I may as well start now by documenting this project:

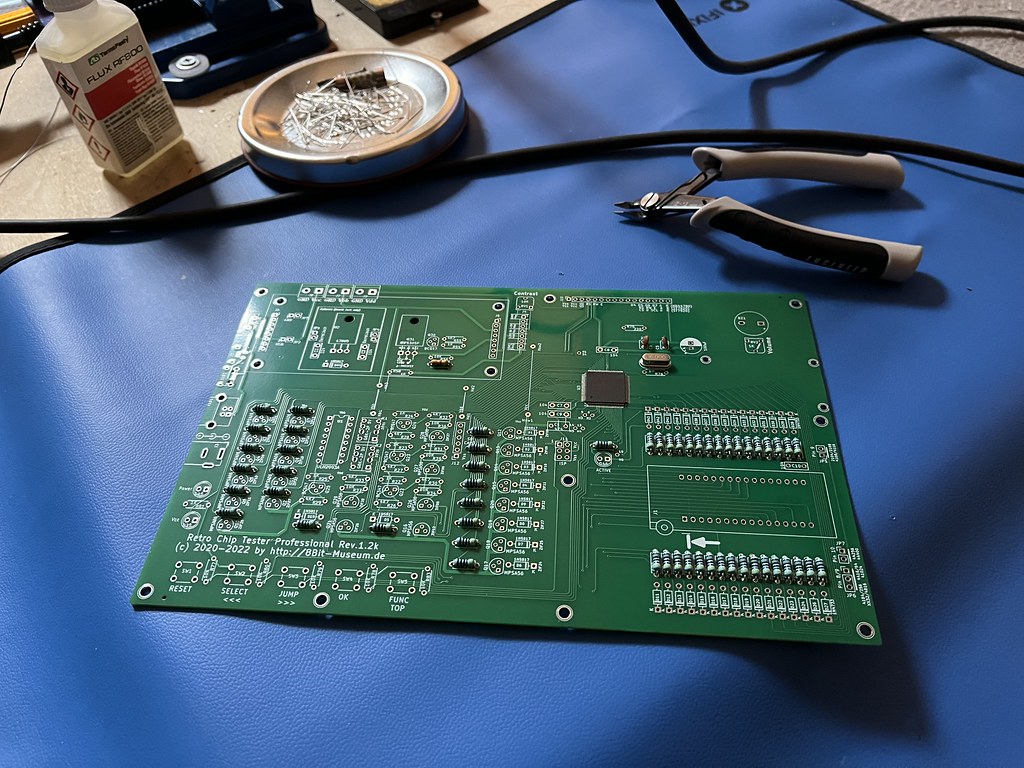

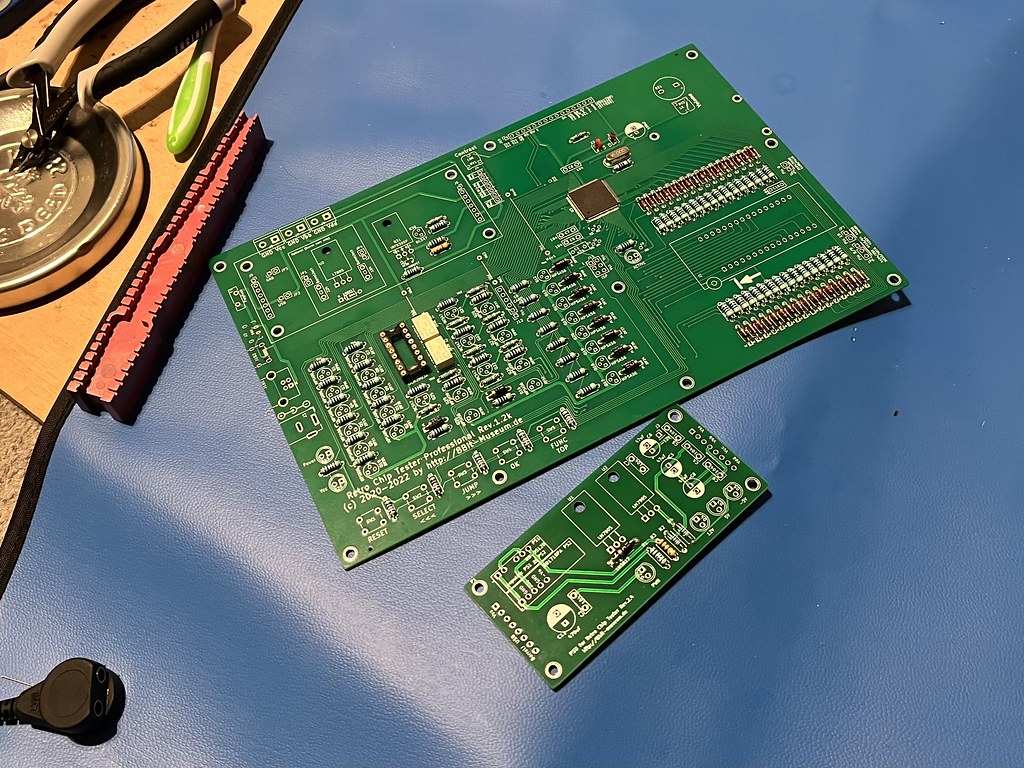

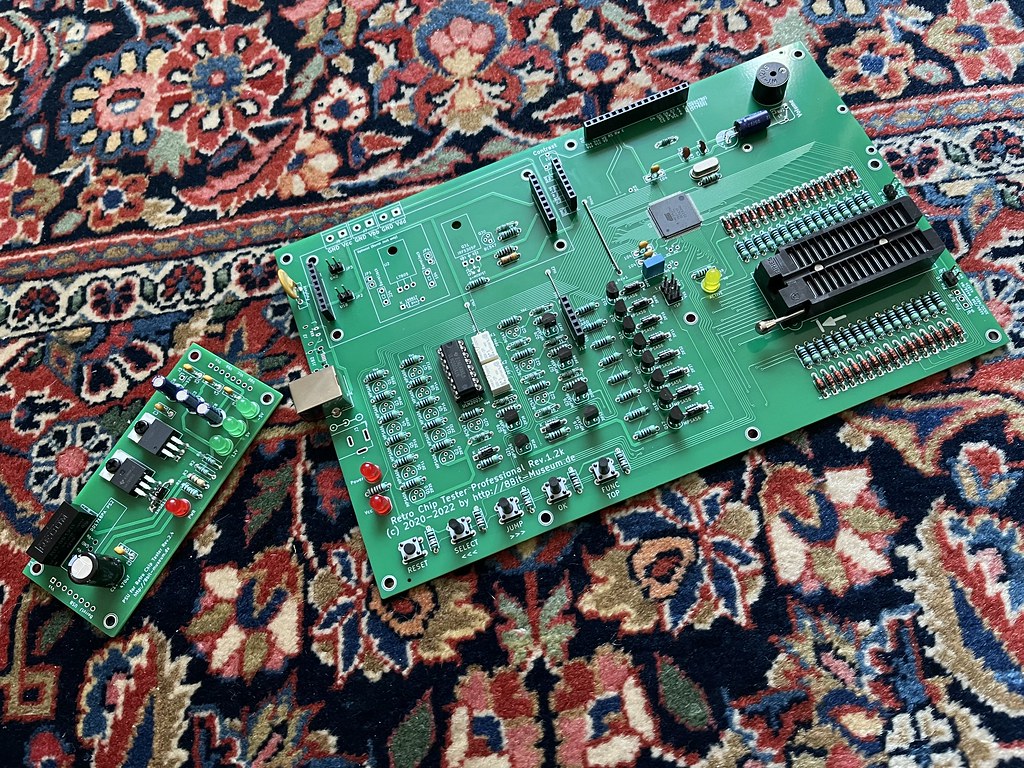

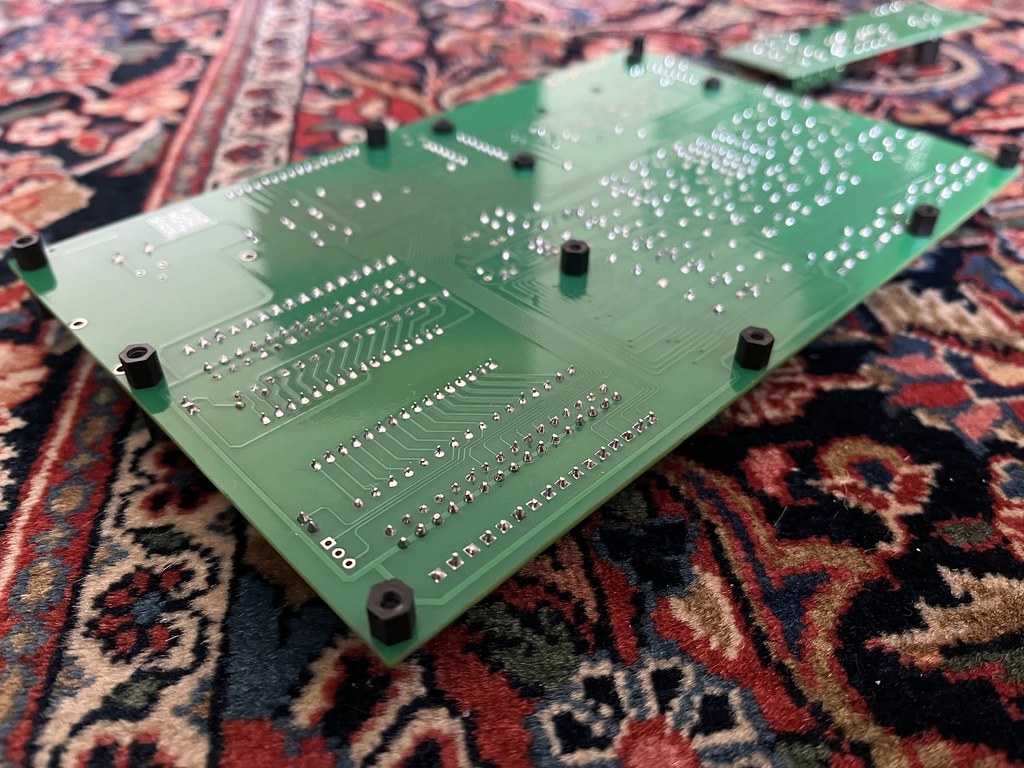

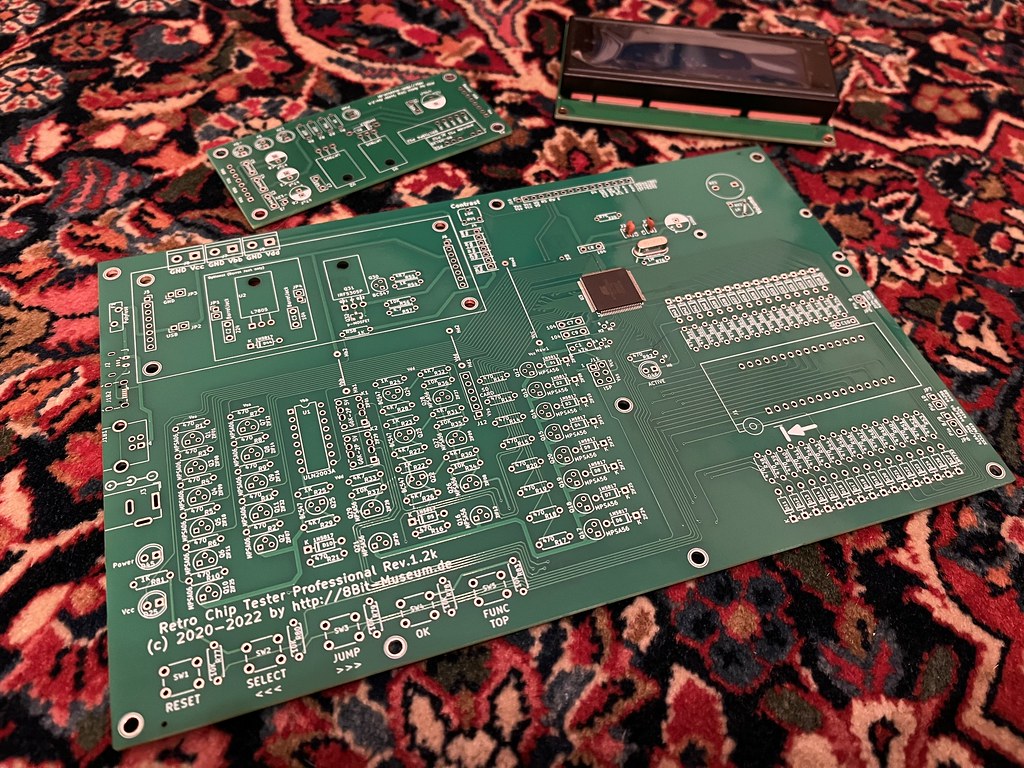

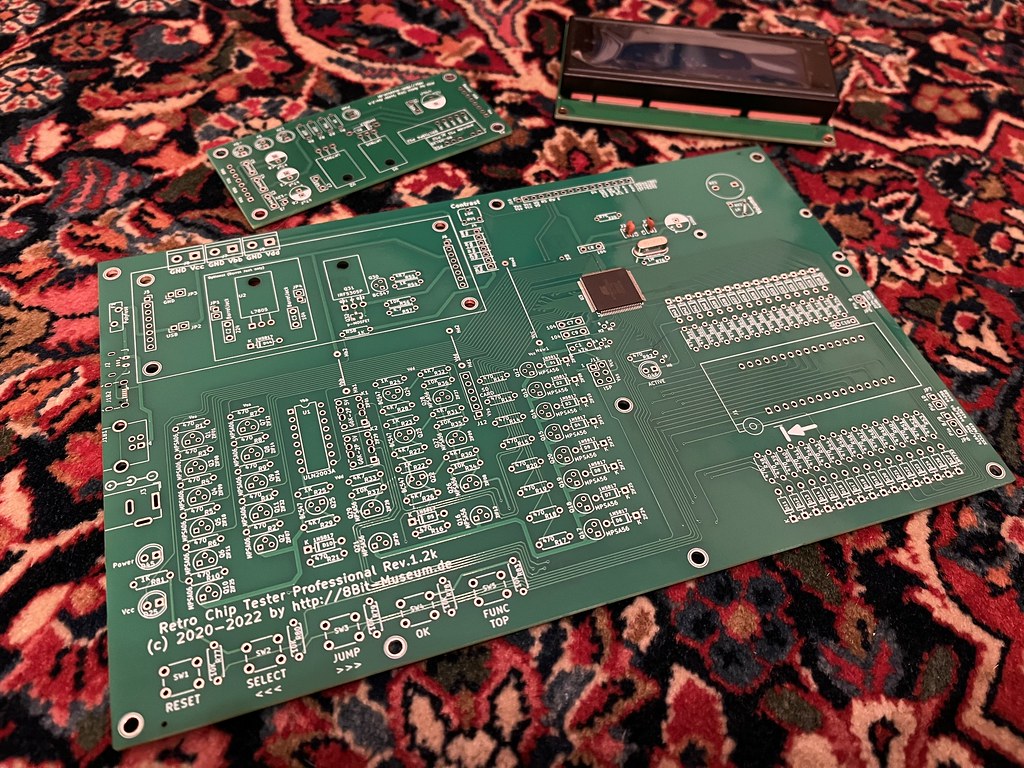

It is hopefully going to be an 8bit-museum.de Chip Tester Pro.

I hit the first big snag when trying to order the bill of materials as the German supplier where the shared basket was stored will not deal with the UK thanks to Brexit. Thanks Brexit. I managed to find a part compiled basket at Digikey and I think I’ve now got about 4/5ths of what I need to throw it together, maybe a bit more. My plan is to build everything I have once it arrives and that will make it easier to figure out what is missing as there will be empty holes!

I opted to have the pre-flashed CPU installed as I didn’t want my first attempt at SMD to be this fiddly or expensive. This isn’t a cheap project, I suspect I’ll be edging towards £200 by the time it is done, but it should vastly improve my ability to tinker around with vintage computers. It can test a vast range of RAM and logic chips, pretty much everything one would find in a BBC Micro, Apple II, Spectrum, C64 etc and may have some uses within audio, I’m not sure. I thought I’d stick a thread here anyway just in case it is if interest.

The Digikey stuff should land next week sometime.

It is hopefully going to be an 8bit-museum.de Chip Tester Pro.

I hit the first big snag when trying to order the bill of materials as the German supplier where the shared basket was stored will not deal with the UK thanks to Brexit. Thanks Brexit. I managed to find a part compiled basket at Digikey and I think I’ve now got about 4/5ths of what I need to throw it together, maybe a bit more. My plan is to build everything I have once it arrives and that will make it easier to figure out what is missing as there will be empty holes!

I opted to have the pre-flashed CPU installed as I didn’t want my first attempt at SMD to be this fiddly or expensive. This isn’t a cheap project, I suspect I’ll be edging towards £200 by the time it is done, but it should vastly improve my ability to tinker around with vintage computers. It can test a vast range of RAM and logic chips, pretty much everything one would find in a BBC Micro, Apple II, Spectrum, C64 etc and may have some uses within audio, I’m not sure. I thought I’d stick a thread here anyway just in case it is if interest.

The Digikey stuff should land next week sometime.