cutting42

Arrived at B4 Hacker Ergo

Hello my loudspeaker chums. Being a serious glutton for punishment and having only just (finally) finished my Ergo IIIR loudspeaker build that took 9 years pretty much; I got talked into building a pair of cabs for another pfm'r. I did warn him it might take a while!

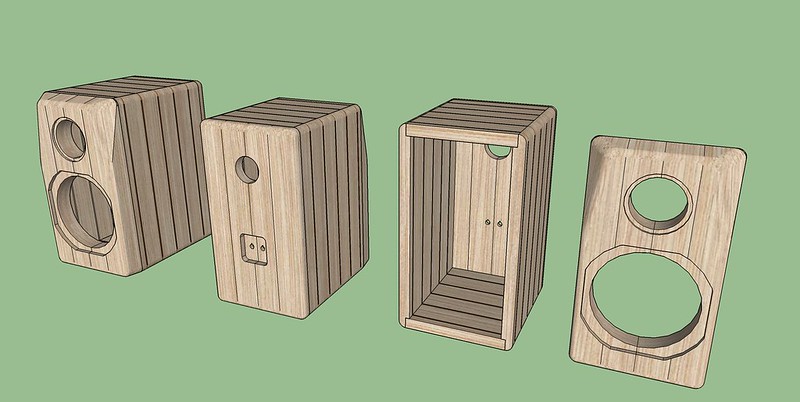

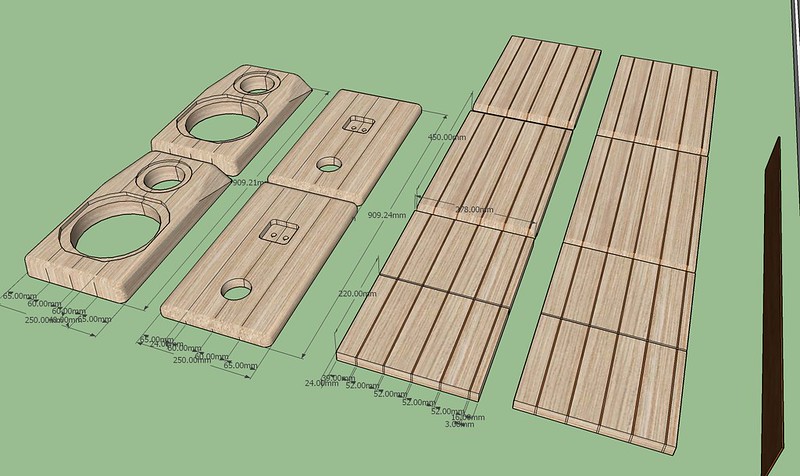

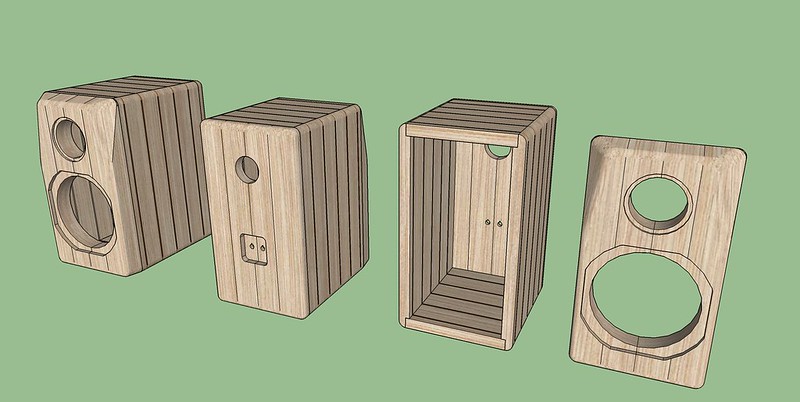

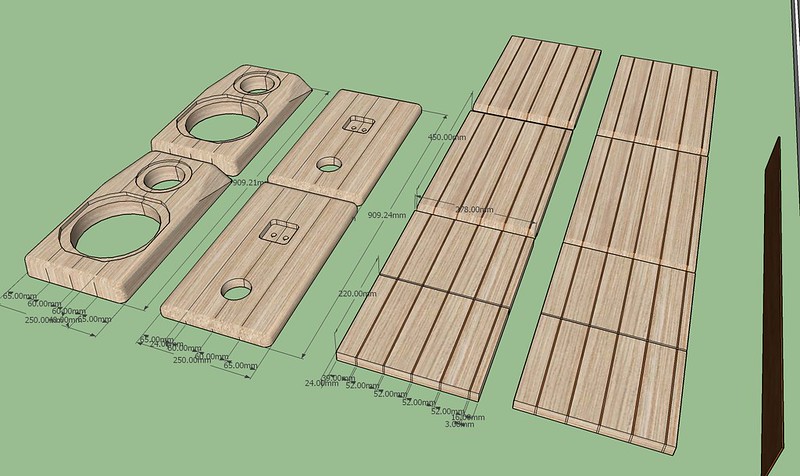

Rest assured it is not another Ergo IIIR, not even I would do that to myself. This time it is make a fancy cabinet for an existing speaker design which is a known quantity. This time I am not using veneers but solid wood with all the challenges of designing to account for movement. We have been inspired by an existing cab but put some design ideas of the pfm'r into it as well to make it our own.

I am very excited to be building in solid wood and as per the title we have selected Maple and Walnut for the cabinet. Sketchup design:

The sawn maple planks as purchased with walnut 3mm strips

After a few weeks settling in the workshop environment I stared marking out the flaws in the planks and working out the cutting plan. The idea is to make up the boards for the whole cab as a sandwich of maple and walnut. To save effort, the plan is to glue up a long piece that can do the sides, top and bottom, get it to dimension and once glued up then cut into smaller pieces to the construction. A similar idea for the front and rear panels.

All the cutting down is now done, roughly 5mm oversize to allow movemetn before we get into accurate planing, thicknessing.

I used some offcuts to tune up the Planer/Thicknesser and get it accurate.

Now the wood has been cut roughly I need to let it stabilise some more as you release tensions in the wood once it has been sawn. Will see if I can get anything done next week.

Rest assured it is not another Ergo IIIR, not even I would do that to myself. This time it is make a fancy cabinet for an existing speaker design which is a known quantity. This time I am not using veneers but solid wood with all the challenges of designing to account for movement. We have been inspired by an existing cab but put some design ideas of the pfm'r into it as well to make it our own.

I am very excited to be building in solid wood and as per the title we have selected Maple and Walnut for the cabinet. Sketchup design:

The sawn maple planks as purchased with walnut 3mm strips

After a few weeks settling in the workshop environment I stared marking out the flaws in the planks and working out the cutting plan. The idea is to make up the boards for the whole cab as a sandwich of maple and walnut. To save effort, the plan is to glue up a long piece that can do the sides, top and bottom, get it to dimension and once glued up then cut into smaller pieces to the construction. A similar idea for the front and rear panels.

All the cutting down is now done, roughly 5mm oversize to allow movemetn before we get into accurate planing, thicknessing.

I used some offcuts to tune up the Planer/Thicknesser and get it accurate.

Now the wood has been cut roughly I need to let it stabilise some more as you release tensions in the wood once it has been sawn. Will see if I can get anything done next week.