You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LP12 Bolt Mod

- Thread starter JMP

- Start date

TPA

Trade: Tiger Paw

You can only really tell how well the top plate is fitted during assembly of the deck. So to check it properly you'd need to strip the deck down (i.e., remove the sub chassis) and then basically tap around the top plate edges to determine if it is solid with the plinth in all areas, particularly the corners. Then of course you're left with the job of re setting the deck which if not done properly could you leave you in a worse place overall.

The corner bolt does help in terms of ensuring that the motor corner area is well connected to the plinth so that motor vibrations are better damped, but if you have a well fitted top plate then it doesn't make much difference. What it did do was add more consistency to deck set up. You can do a mod by either drilling a hole in the corner area and the corner brace and fitting a long M5 bolt, or by picking up a S/H top plate with the corner bolt already brazed on, there are quite a few of these about now.

The corner bolt does help in terms of ensuring that the motor corner area is well connected to the plinth so that motor vibrations are better damped, but if you have a well fitted top plate then it doesn't make much difference. What it did do was add more consistency to deck set up. You can do a mod by either drilling a hole in the corner area and the corner brace and fitting a long M5 bolt, or by picking up a S/H top plate with the corner bolt already brazed on, there are quite a few of these about now.

YNWOAN

100% Analogue

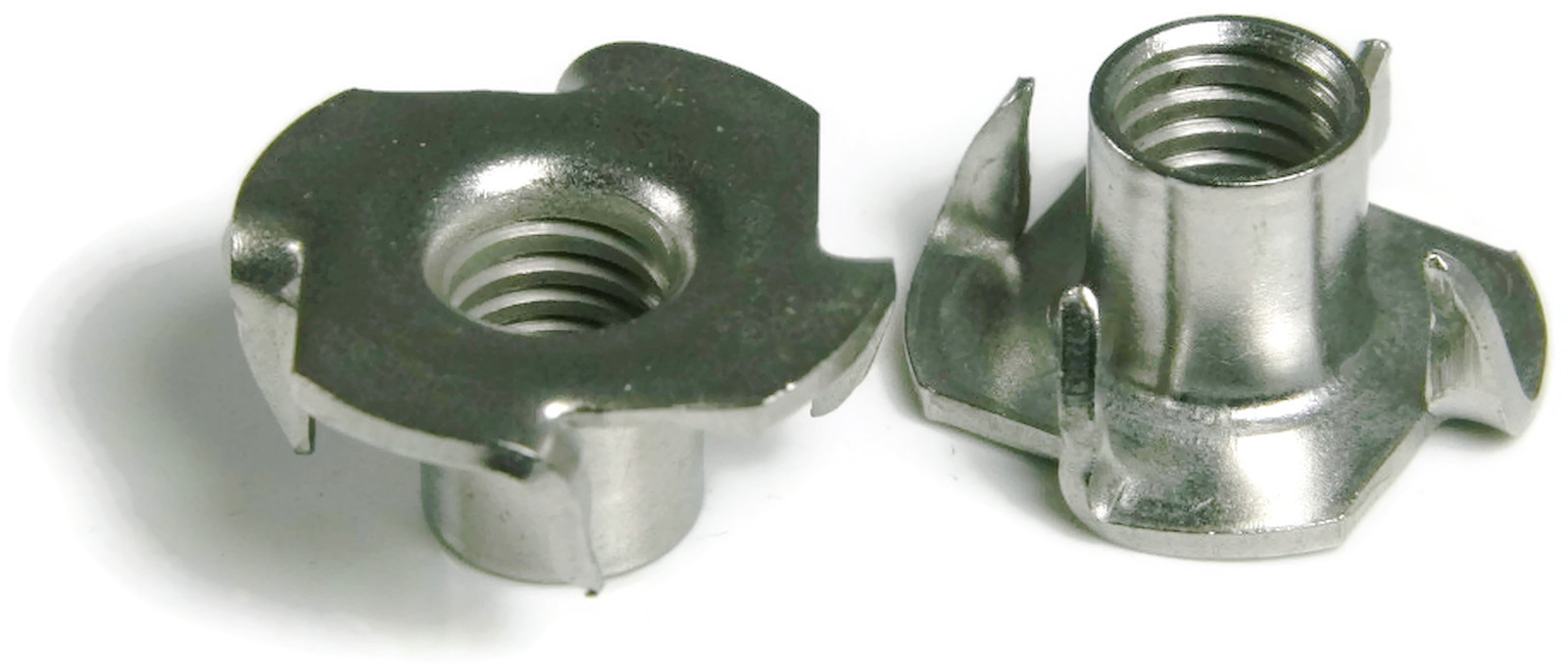

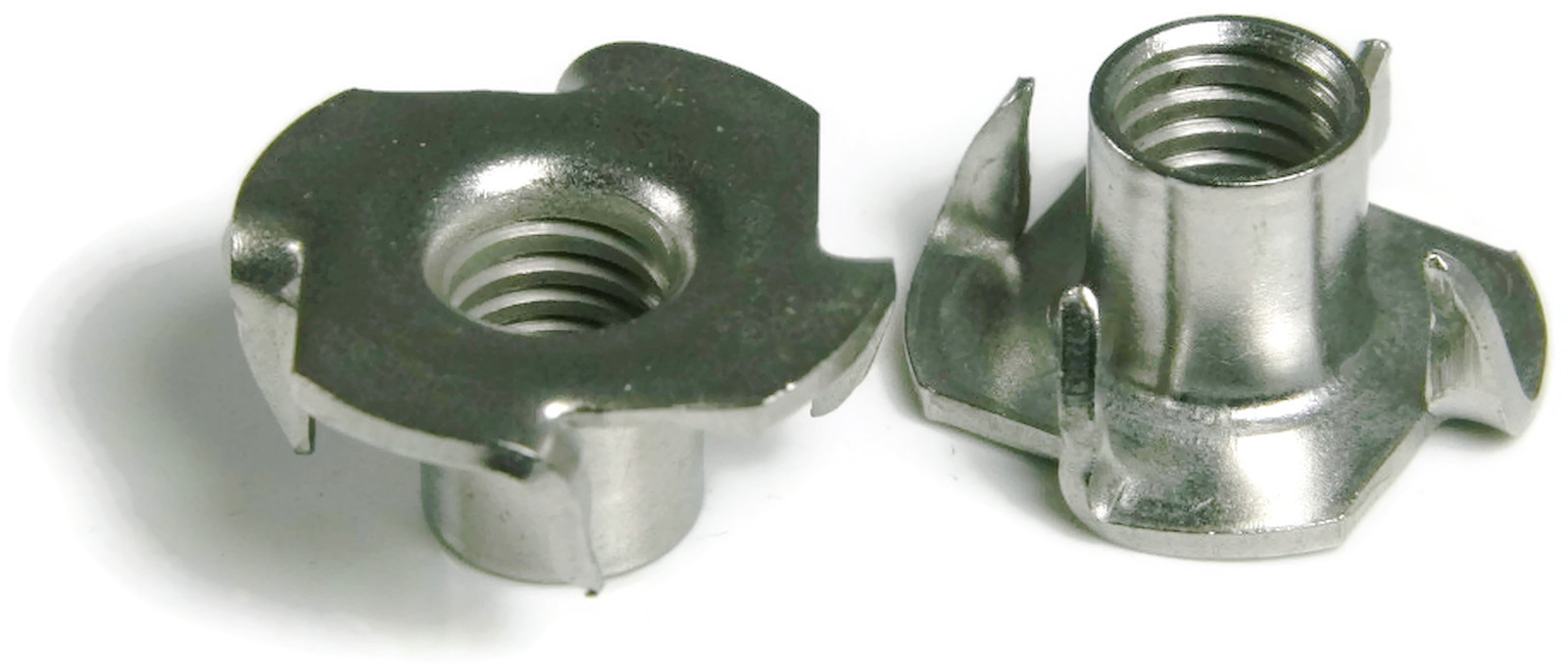

If you use a T-nut:

You can tap the spikes flat with a small hammer and epoxy it to the underside of the top plate. You then drill a hole in the corner brace (you do need a corner braced plinth) and fit the correct length bolt - don't over tighten it. You are probably best drilling the hole first and using this to help align the T-nut for gluing.

Personally, I don't think you need to strip the deck to check for this issue and my suggestion paraphrased the Linn service manual.

You can tap the spikes flat with a small hammer and epoxy it to the underside of the top plate. You then drill a hole in the corner brace (you do need a corner braced plinth) and fit the correct length bolt - don't over tighten it. You are probably best drilling the hole first and using this to help align the T-nut for gluing.

Personally, I don't think you need to strip the deck to check for this issue and my suggestion paraphrased the Linn service manual.

jimification

pfm Member

I did it and think it's worth doing - a small difference but cheap and easy to do and these things all add up. Apart from stopping any rattles, maybe it does help transfer some motor vibration deeper into the plinth via the bolt / corner brace, as Roger suggested.

As Mark said above, just drill a suitable hole through the corner brace and araldite a T nut to the underside of the top plate is the easiest way. You can use the same bolt via a temporary nut on top of the corner brace to exert a little pressure on the T nut whilst the epoxy is drying.

FWIW: When Peter Swain was setting up my LP12, I noticed that he placed a lot more emphasis on the top plate fit than the fabled "bounce"...

As Mark said above, just drill a suitable hole through the corner brace and araldite a T nut to the underside of the top plate is the easiest way. You can use the same bolt via a temporary nut on top of the corner brace to exert a little pressure on the T nut whilst the epoxy is drying.

FWIW: When Peter Swain was setting up my LP12, I noticed that he placed a lot more emphasis on the top plate fit than the fabled "bounce"...

YNWOAN

100% Analogue

Yes, I do think the top plate tightness to the plinth makes a significant difference and vibration at the motor corner is certainly not a good thing. Linn's solution of bowing the top plate is elegant in a sense but it isn't as effective as it could be. I've recently had a chance to play around with a Khan top plate and that certainly seems to give a more solid and consistent contact to the plinth (it bolts to it at a number of points).

I found it made a small but worthwhile improvement in tightening up the sound. However my bolt mod came apart as I hadn't cleaned the parts properly before epoxying. Haven't put it back yet as I'll wait until the spirit comes over me and I take it apart and swap the springs around etc. Cheers, Rolf

flatpopely

Prog Rock/Moderator

Yes, I do think the top plate tightness to the plinth makes a significant difference and vibration at the motor corner is certainly not a good thing. Linn's solution of bowing the top plate is elegant in a sense but it isn't as effective as it could be. I've recently had a chance to play around with a Khan top plate and that certainly seems to give a more solid and consistent contact to the plinth (it bolts to it at a number of points).

I think I am going to (well you are!) finally going to fit the Khan to my deck!

John

Rack’em Up!

You can only really tell how well the top plate is fitted during assembly of the deck. So to check it properly you'd need to strip the deck down (i.e., remove the sub chassis) and then basically tap around the top plate edges to determine if it is solid with the plinth in all areas, particularly the corners. Then of course you're left with the job of re setting the deck which if not done properly could you leave you in a worse place overall.

The corner bolt does help in terms of ensuring that the motor corner area is well connected to the plinth so that motor vibrations are better damped, but if you have a well fitted top plate then it doesn't make much difference. What it did do was add more consistency to deck set up. You can do a mod by either drilling a hole in the corner area and the corner brace and fitting a long M5 bolt, or by picking up a S/H top plate with the corner bolt already brazed on, there are quite a few of these about now.

You definitely want to check for rattles when it's stripped down. Too tight kills the sound!

Gaius

pfm Member

You definitely want to check for rattles when it's stripped down. Too tight kills the sound!

You are absolutely right, too tight kills the sound of both Khan and Karmen.

For those curious, they are both on dem at Cymbiosis.

flatpopely

Prog Rock/Moderator

Oh, am I!

No. Prob.

It's a date!

James

Lord of the Erg\o/s

My LP12 has a well-fitted top-plate, to which I applied the bolt-mod as described. I certainly found that anything thing more than just nipped up to provide a light tension absolutely killed the Linn groove.You definitely want to check for rattles when it's stripped down. Too tight kills the sound!

I have since fitted the Khan, taking care to secure the bolts with just enough tension for a secure fit.

Been there done (and undone) the bolt mod.

I found that taking time to get the top plate formed correctly is all that's required to make the motor corner (and switch corner) rattle free. The flaw inherent in the bolt mod is that it introduces one extra tuneable component into the (arguably) already too tweaky LP12. Aftermarket top plates with multiple 'bolts' are an extension of that - for good or bad.

Mr Tibbs

I found that taking time to get the top plate formed correctly is all that's required to make the motor corner (and switch corner) rattle free. The flaw inherent in the bolt mod is that it introduces one extra tuneable component into the (arguably) already too tweaky LP12. Aftermarket top plates with multiple 'bolts' are an extension of that - for good or bad.

Mr Tibbs

TPA

Trade: Tiger Paw

Been there done (and undone) the bolt mod.

I found that taking time to get the top plate formed correctly is all that's required to make the motor corner (and switch corner) rattle free. The flaw inherent in the bolt mod is that it introduces one extra tuneable component into the (arguably) already too tweaky LP12. Aftermarket top plates with multiple 'bolts' are an extension of that - for good or bad.

Mr Tibbs

I agree that it's the fit of the top plate that is the important issue, as opposed to the bolt per se, but as I said before, it did permit a greater level of consistency to be achieved and having now come across an awful lot of different LP12s I can tell you that the variability in set up is underwhelming.

The thinking behind things like the Khan is not really to enable a better connection to the plinth, but to actually act as a better platform for the motor and suspension as opposed to a a sheet of thin stainless steel where in order to work ok becomes exceedingly critical. The whole deck becomes a lot more predictable; the spring carrier bolts are now vertical so the suspension is easier to set up, motor vibration is absorbed and it's connection to the plinth is now much more effectively achieved.

Hi!

thanks for advices guys.

Will take time to check everything. Not sure I have the right dull thud when taping on the corner.

Maybe a full rebuilt would be a good thing.

Will see what I'll do. Unfortunately, I don't have access to LP12 expert/dealer around here, so will have to do this by myself.

Happy christmas everyone!

thanks for advices guys.

Will take time to check everything. Not sure I have the right dull thud when taping on the corner.

Maybe a full rebuilt would be a good thing.

Will see what I'll do. Unfortunately, I don't have access to LP12 expert/dealer around here, so will have to do this by myself.

Happy christmas everyone!

Gaius

pfm Member

JMP

In this very detailed thread from Peter Swain of Cymbiosis you will find pretty much every aspect of setting up an LP12 covered.

http://forums.linn.co.uk/bb/showthread.php?tid=9941

In this very detailed thread from Peter Swain of Cymbiosis you will find pretty much every aspect of setting up an LP12 covered.

http://forums.linn.co.uk/bb/showthread.php?tid=9941

Thank you Gaius.

Yes, I know this thread. I made me a PDF of it. I also have a copy of the Linn Setup manual.

In fact, my LP12 is not that bad I have managed to set it up quite nicely already (got it for more than 10 years), sounds quite good.

I have managed to set it up quite nicely already (got it for more than 10 years), sounds quite good.

It has a very nice pistonic bounce, but I think I've overlooked a few details ....

JMP

Yes, I know this thread. I made me a PDF of it. I also have a copy of the Linn Setup manual.

In fact, my LP12 is not that bad

It has a very nice pistonic bounce, but I think I've overlooked a few details ....

JMP