Dowser

Learning to bodge again..

LOL Si - understood. I should actually have looked at my arms before posting anyhow - I have no problems, see below.

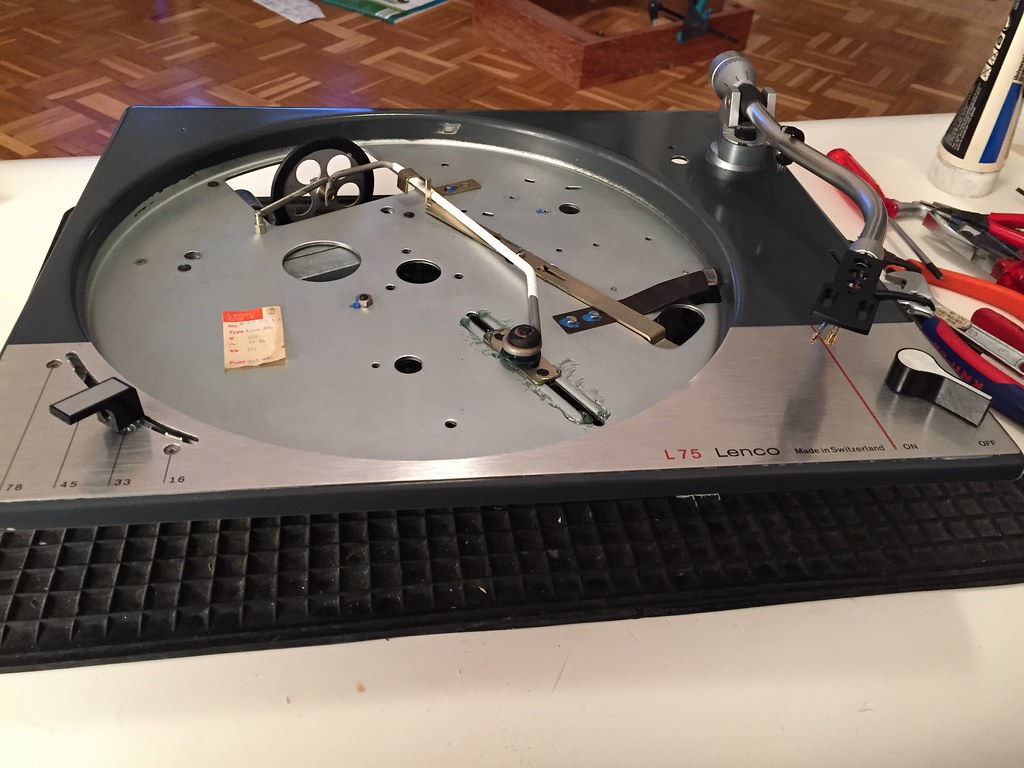

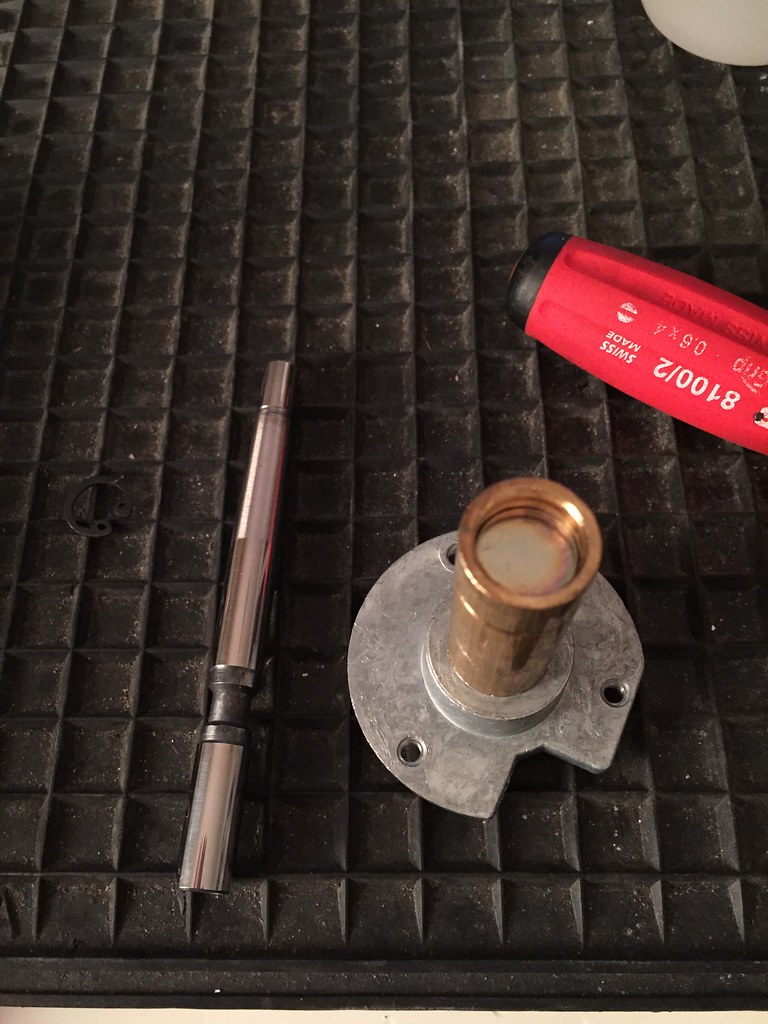

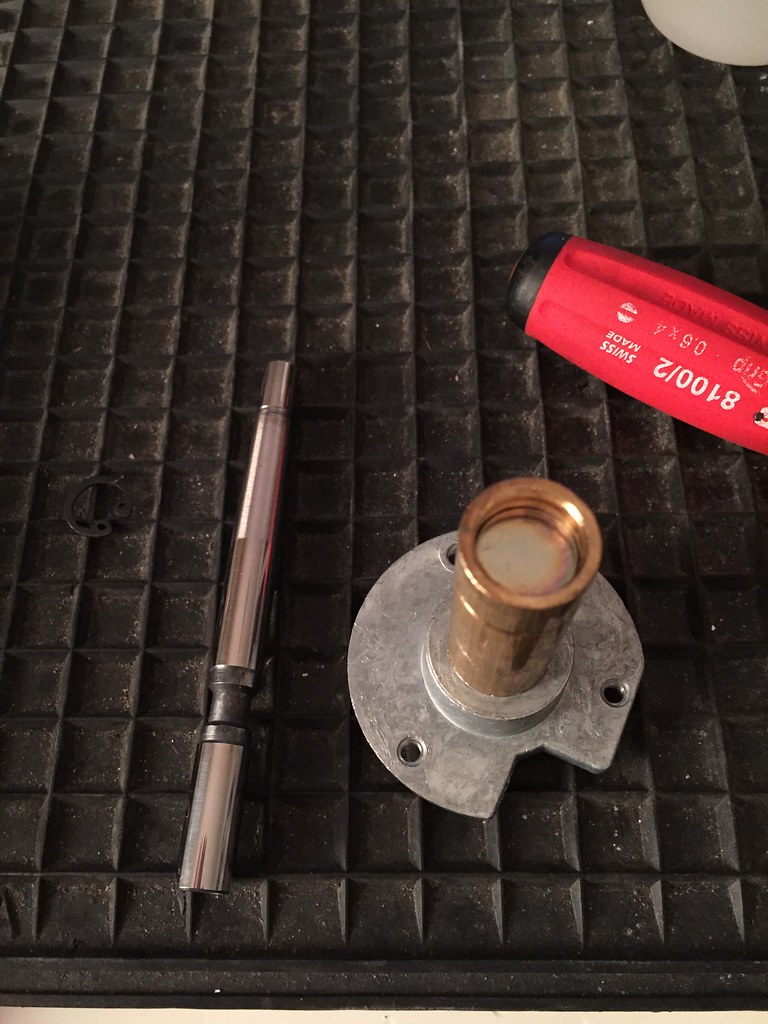

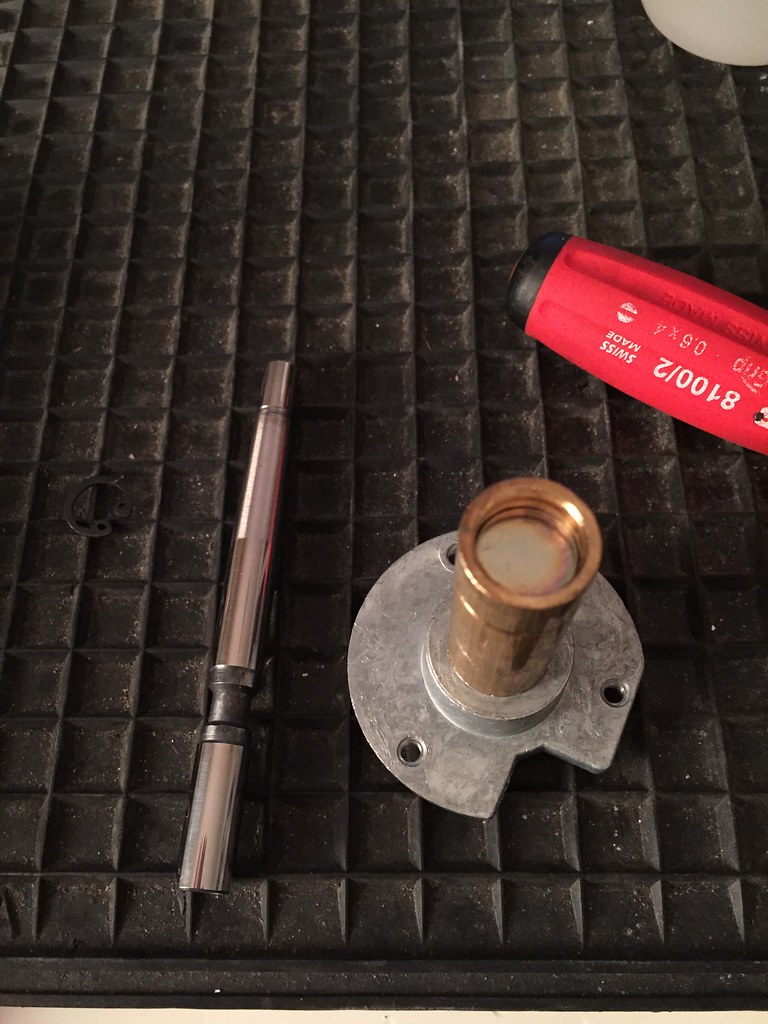

So tonight I got half an hour to rebuild the bearing - reading up on LH, I decided to deviate a little to try and make bearing oil tight with grease - it's worked for an hour so far;

Everying cleaned with alcohol

Test fit of bearing suface and base plates

]

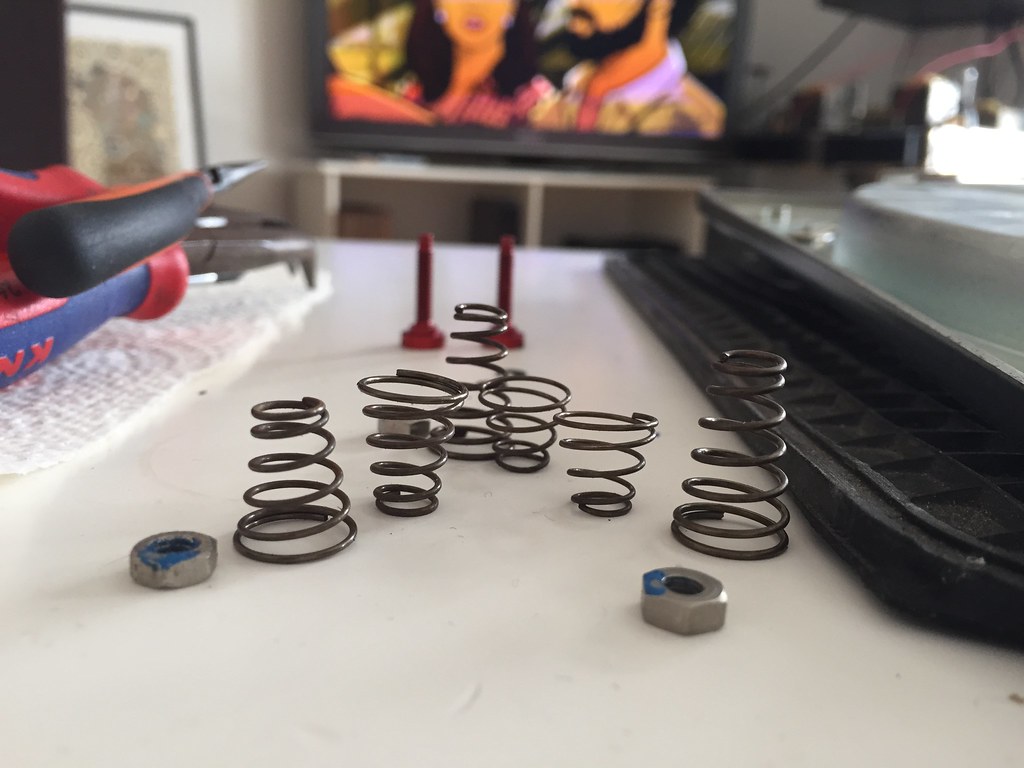

I then fitted bearing (delrin?) plate, and packed behind with grease, then fitted metal plate, then fitted circlip & pushed everything down onto circip

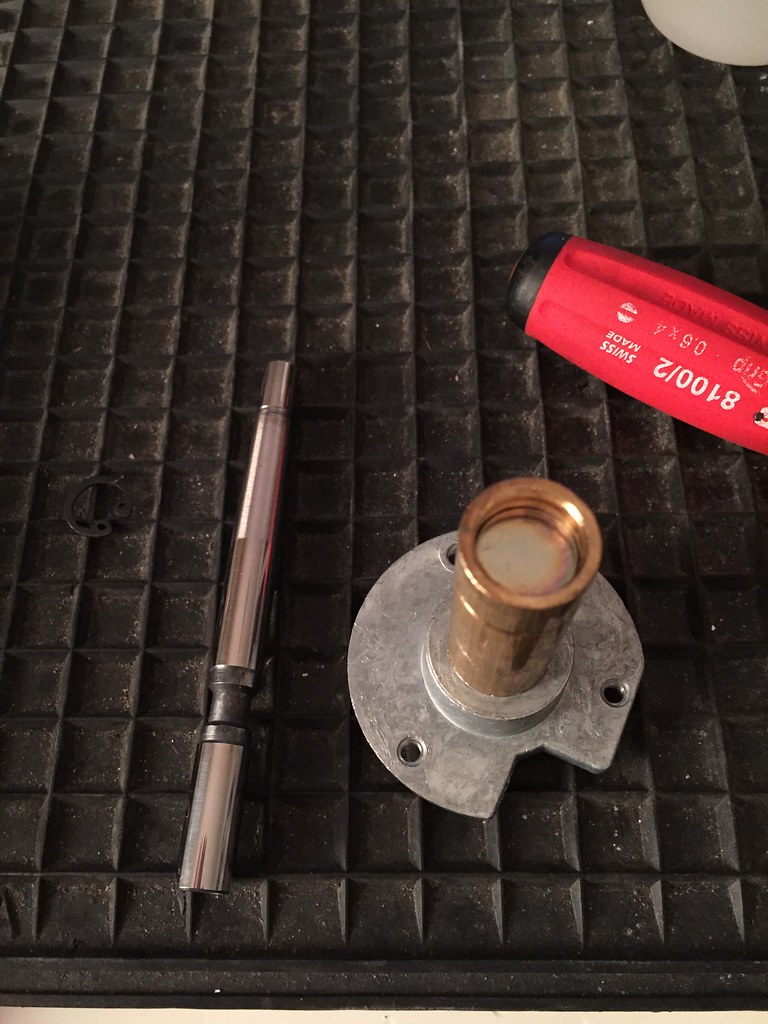

I then pushed on plastic end cap (note very clean spindle ), and filled oil, fitted spindle (cleaned up oil), and again filled after fitting spindle, then locked spindle screw with estranged wife's spare nail varnish

), and filled oil, fitted spindle (cleaned up oil), and again filled after fitting spindle, then locked spindle screw with estranged wife's spare nail varnish

After letting oil settle I tried filling from bearing top - nothing soaking down into bearing so just fitted felt washer (no photo) and left it to see if it leakes oil - so far so good

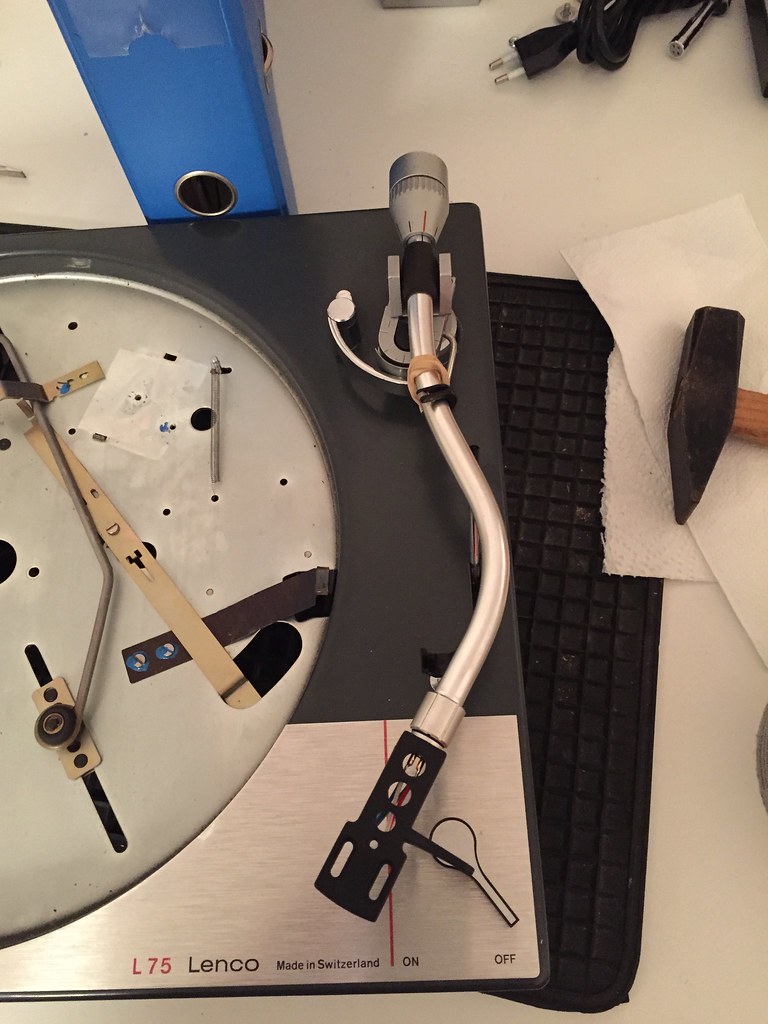

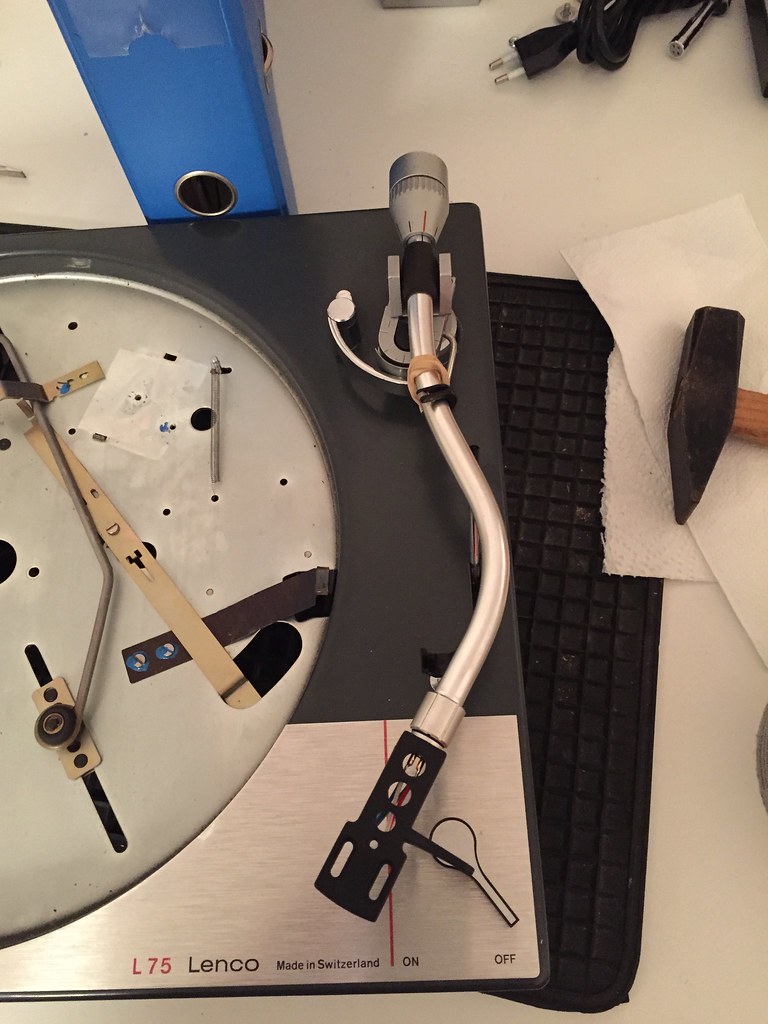

So now arms - POrtofon AS-212 comes with everything (includinf manual!), its an MKII;

[/url]

[/url]

It has a collar, which fits into the Lenco hole with a mm or so to spare - I can lock this up no problem (and have enough room to play to correct for 2mm mounting length difference (either via hole of headshell slots);

Mine has a Linn style socket in the bottom (was this stock?), and what looks like screws to remove headshell connector (anyone know for sure - should I rewire this arm before fitting?!)

Should I choose to rewire, anyone know how to get arm apart? Can I remove both screws shown here and remove pillar and left/right bearing?

[/url]

[/url]

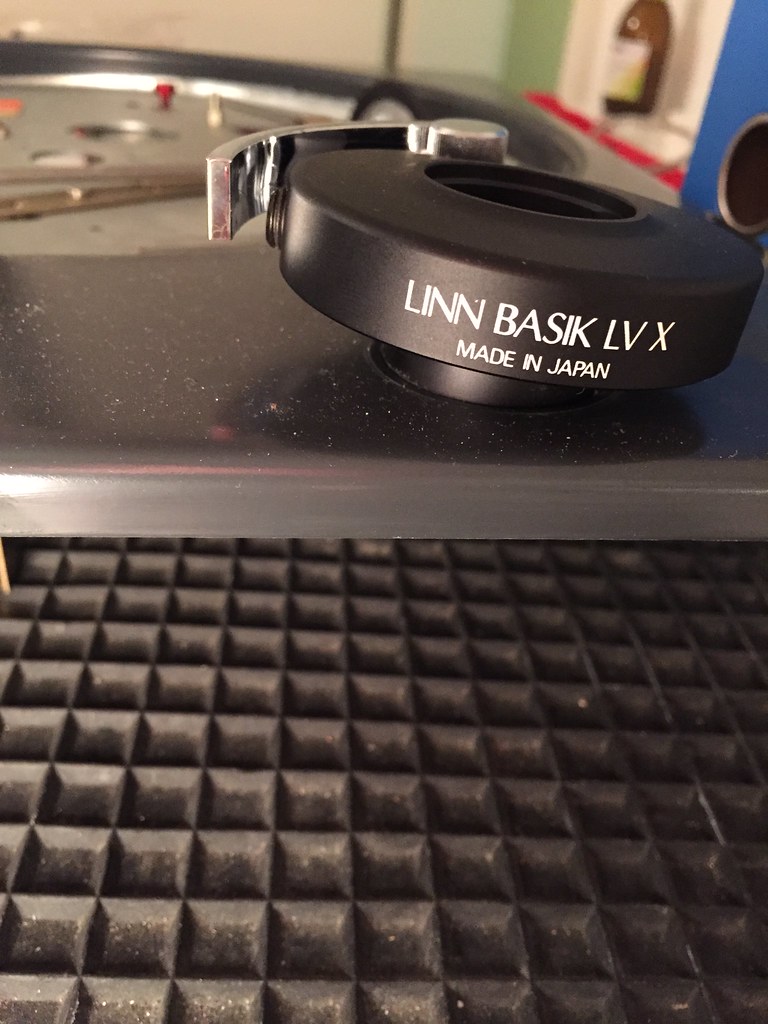

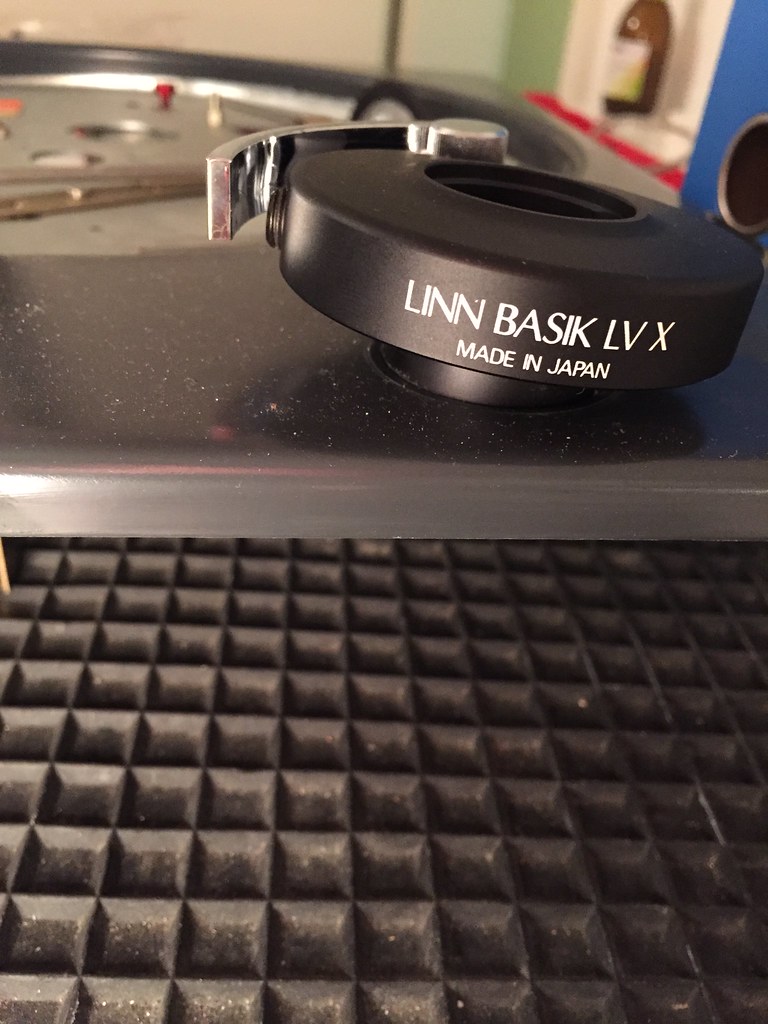

Basik LVX arm also comes with collar, L75 top plate only needs a little filing to get it to fit

[/url]

[/url]

But need to fix arm mount clip

Regardless, I do not like the Linn headshell fixing - too much play even when tightened, the Ortofon is much better. Ortofon has perhaps .1mm left/right (arm swing) bearing play, which is more than Linn, but I will try to adjust Ortofon. So, AS-212 it is.

It means I remove all the Lenco arm lift gubbins, so will have a couple of holes in top plate.

Finally, I never realised, guy who sold me the Linn also provided a Roksan manual VTF uage...look at photos, "Denmark" is on clear plastic holder, so guess its Ortofon - what was price difference between the two I wonder? No big deal for me - Corus Black is a likely MM to try in the Ortofon arm

Thanks, Richard

So tonight I got half an hour to rebuild the bearing - reading up on LH, I decided to deviate a little to try and make bearing oil tight with grease - it's worked for an hour so far;

Everying cleaned with alcohol

Test fit of bearing suface and base plates

]

I then fitted bearing (delrin?) plate, and packed behind with grease, then fitted metal plate, then fitted circlip & pushed everything down onto circip

I then pushed on plastic end cap (note very clean spindle

After letting oil settle I tried filling from bearing top - nothing soaking down into bearing so just fitted felt washer (no photo) and left it to see if it leakes oil - so far so good

So now arms - POrtofon AS-212 comes with everything (includinf manual!), its an MKII;

It has a collar, which fits into the Lenco hole with a mm or so to spare - I can lock this up no problem (and have enough room to play to correct for 2mm mounting length difference (either via hole of headshell slots);

Mine has a Linn style socket in the bottom (was this stock?), and what looks like screws to remove headshell connector (anyone know for sure - should I rewire this arm before fitting?!)

Should I choose to rewire, anyone know how to get arm apart? Can I remove both screws shown here and remove pillar and left/right bearing?

Basik LVX arm also comes with collar, L75 top plate only needs a little filing to get it to fit

But need to fix arm mount clip

Regardless, I do not like the Linn headshell fixing - too much play even when tightened, the Ortofon is much better. Ortofon has perhaps .1mm left/right (arm swing) bearing play, which is more than Linn, but I will try to adjust Ortofon. So, AS-212 it is.

It means I remove all the Lenco arm lift gubbins, so will have a couple of holes in top plate.

Finally, I never realised, guy who sold me the Linn also provided a Roksan manual VTF uage...look at photos, "Denmark" is on clear plastic holder, so guess its Ortofon - what was price difference between the two I wonder? No big deal for me - Corus Black is a likely MM to try in the Ortofon arm

Thanks, Richard