I've posted something similar before, but to re-iterate I tried a Lampizator back in 2012 and liked it, previous players were well respected - Marantz CD94, Meridian 508.24, Wadia, Dax etc. I have no allegiances with any technology or brand - if I like the sound then it stays until I hear something better. Maybe I sacrified some detail for listenability, maybe not, but it certainly sounded more REAL, as in a musical event rather than a pastiche and given they were played through NS1000's not much would have been missing ( except low bass ). This was reflected in the fact that I played a lot more CD's and less vinyl. I went down a similar vein with the ANK. You can argue the toss as to whether they would sound the same with a solid state output or not. I will be trying some of the latest DACs - if they sound better then the ANK goes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is there any point in a valve DAC

- Thread starter rockingdoc

- Start date

earlofsodbury

Wastrel.

Apologies if my comment came across that way...

Seemed clear enough to me - but then I remember Fikus' early days as a highly opinionated amateur blogger - outspoken to say the least, critical of every piece of equipment he handled, undertaking rather slipshod looking modifications to the same - which were then sold-on to fund the next piece.

I especially recall his scathing reports on Audionote (a company I'm highly ambivalent about as well, FWLIW), and yet some years later some remarkably reminiscent designs appeared on his workbench ... and now - he makes his living selling stratospherically-priced, hyperbolically-marketed microbrand valve hifi...

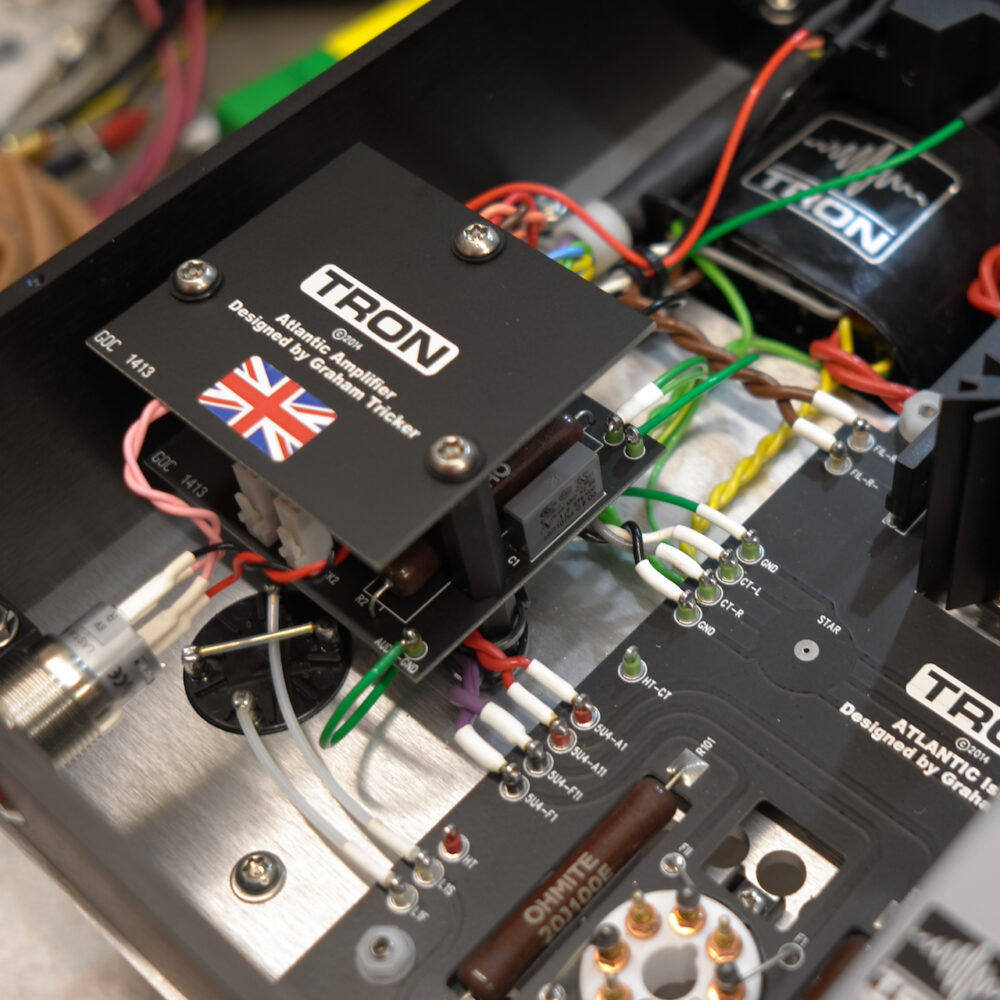

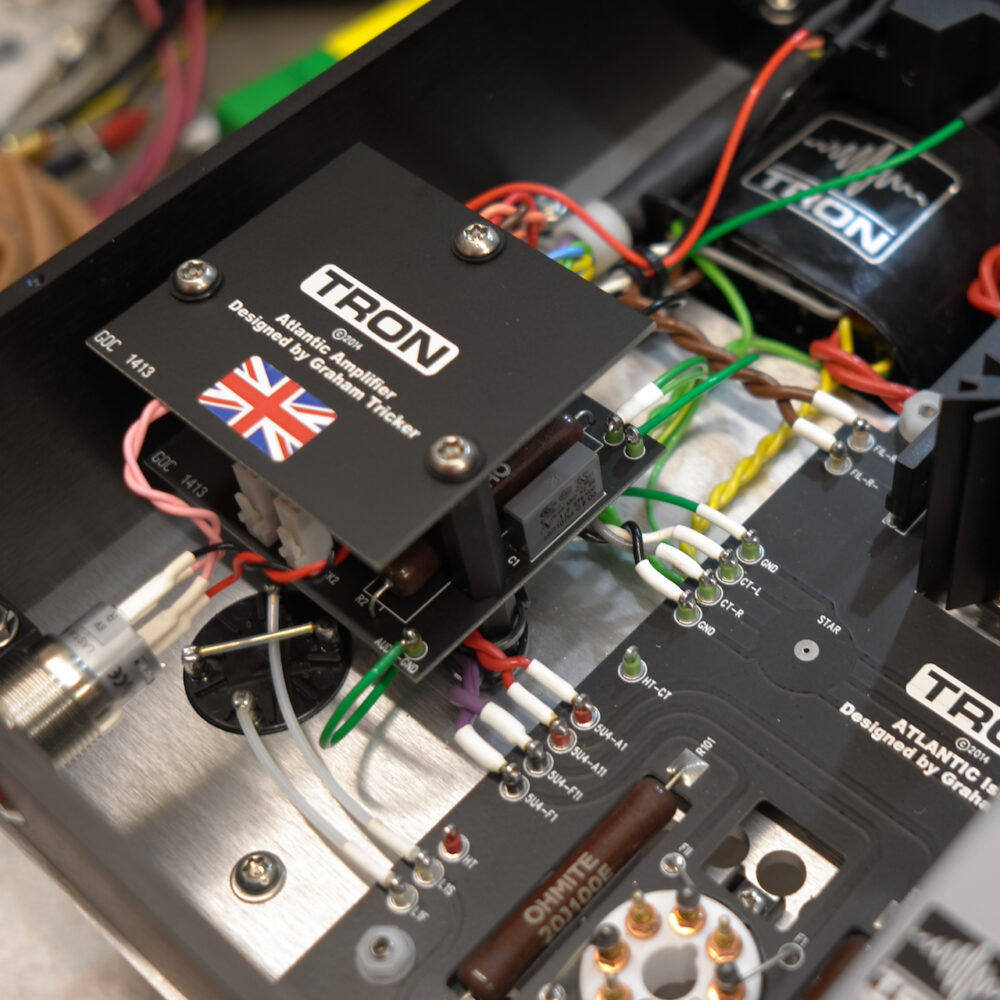

Going on looks alone ... let's just say I'd like to see the CE conformity documentation...

Arkless Electronics

Trade: Amp design and repairs.

Apologies if my comment came across that way. It was meant to highlight this aspect of equipment which should most definitely be considered when spending sizeable sums on audio products. IMO, if you make a product everything should be addressed, the design, the construction, the performance, consumer safety and CE. Over the past 40 years that I have been involved in audio, I have seen and witnessed poor build quality in equipment which has given this industry a bad name, especially to small companies who specialise in offering performance that the bigger companies can't match for the price. No one mentions it, not even the reviewers, probably as most wouldn't know what was good design and good construction, and most audiophiles have no clue either, especially today. Ultimately, it is up to the buying individual to make the choice, but they should be aware of what they are buying. There is no excuse for poor build quality.

Note: before I started manufacturing, I used to service and repair all of the top high end HiFi for several shops and distributors. I was totally horrified when working on some of this equipment how poor some of it was. This was one of the factors in why I started my own manufacturing brand. I remember opening up a 300B amplifier made here in the UK and I was aghast when I took the bottom panel off, as the outside of the chassis was sprayed black, but on opening it up the inside was full of rust. They had painted the outside of the case but not the inside. It would have only cost pennies to run the spray gun around the inside of the chassis. Also, to fill up a few holes in the back panel, 2 pence pieces were glued to the inside of the chassis and filled and sprayed on the outside. Thankfully the company that made this didn't last very long. Occasionally I was pleasantly surprised when something good arrived and it was aways a pleasure and a privilege to work on such equipment.

As you may have seen in some previous posts on the subject one of my bete noires is equipment being made to look internally like "eye candy", often with little or no regard for electrical best practice, and of the risk of those without the experience to know better then judging all equipment by the appearance of good build quality when it in fact is poor. Things like the layout being made completely symmetrical to please the eye when in fact the wiring or PCB tracks have had to be made three times as long and pass by transformers etc in order to do so.

Electrolytics put right next to heatsinks to make room for eye pleasing layout in the space so saved. Wiring looms having mains wiring and low level signal wiring bundled together cos it looks neater etc etc.

Another common one (though potentially harmless) is the deliberate choice of film caps in an array of bright primary colours to make it look pretty... liquorice allsorts!

The "if it's metal gold plate it" thing is also seen very often. Money that could have been spent on better parts etc is spent on gold plating all sorts of stuff where there is no electrical need for the non tarnishing properties of gold.... it just looks nice.

When I have to use a PCB, I spend days alongside my PCB designer to get the layout perfect for the shortest signal path as well as a nice clean layout. We set up rules in the software where it won't let you put certain tracks next to ones that carry the signal or near power supply rails etc, or certain components, like electrolytic capacitors for example, within a certain distance of anything that generates heat as in a regulator, or a high power resistor. Also, because I build each board myself, if I see something during assembly that I am not 100% happy with, I make a note so that when the next batch of boards is needed, an update is made to the board which resolves my concerns. Doing this costs a considerable amount of money, but the circuit board is perfect when it is completed. When I first started using PCBs it used to take me about three to four versions to get the board perfect, but now I can get it done in one to two versions. I also use the best quality board materials so that if any service work is needed (extremely rare occurrence), parts can be removed or replaced without any track or soldered pads being damaged.

earlofsodbury

Wastrel.

When I have to use a PCB...

Not wishing to blow the proverbial smoke, but that is a joy to behold.

Roog

pfm Member

Your slagging off a product that he successfully modified

No that is not what i said, I said that in his Blog circa 2007 he does not follow basic and well established principles of digital design and it all depends on what you define as successful. Mullered would be more accurate.

but you failed to replicate the experiment yourself.

You know nothing of me or my work, so you are not in a position to comment.

You state your skills are much higher than Lampizator.....I find that a bit boastful,

Based on the images he posts on his blog, mine are a lot lot better and safer.

especially considering you were actually copying Lampizator.

If you knew what you were talking about you would know that his blog is based on the application of a standard circuit. Its nothing new, but it did prompt me to see how it worked. Most manufactures don't do what he did because its wrong. If you where to look at the wave form coming from a 'lampizator conversation' you might understand. If you like the idea of a box which changes the input waveform into something similar but with square edged step changes all over it, terrific.

Lukas is clearly an entrepreneur but his conversions identified in his blog from 2007 are grim.

No that is not what i said, I said that in his Blog circa 2007 he does not follow basic and well established principles of digital design and it all depends on what you define as successful. Mullered would be more accurate.

but you failed to replicate the experiment yourself.

You know nothing of me or my work, so you are not in a position to comment.

You state your skills are much higher than Lampizator.....I find that a bit boastful,

Based on the images he posts on his blog, mine are a lot lot better and safer.

especially considering you were actually copying Lampizator.

If you knew what you were talking about you would know that his blog is based on the application of a standard circuit. Its nothing new, but it did prompt me to see how it worked. Most manufactures don't do what he did because its wrong. If you where to look at the wave form coming from a 'lampizator conversation' you might understand. If you like the idea of a box which changes the input waveform into something similar but with square edged step changes all over it, terrific.

Lukas is clearly an entrepreneur but his conversions identified in his blog from 2007 are grim.

Mounting axial caps standing and having a couple of cm antenna doesn't look 100 %, but it's what I would do hotrodding my own gear, but don't expect to see it in a commercial product.

Those capacitors have one leg much longer than the other to facilitate circuit board mounting installations. The capacitors are made to be pretty much square (diameter is equal or bigger than the length) to enable circuit board mounting, so it is perfectly OK to mount these capacitors in this way. Also, where they are in the circuit is very low impedance plus the signal at that point is 2 volts output.

Arkless Electronics

Trade: Amp design and repairs.

Mounting axial caps standing and having a couple of cm antenna doesn't look 100 %, but it's what I would do hotrodding my own gear, but don't expect to see it in a commercial product.

It's absolutely fine and was commonly done in 60's and 70's gear when axial caps were the norm but board space had to be saved.