Minio

Kind of Sort of Not really...

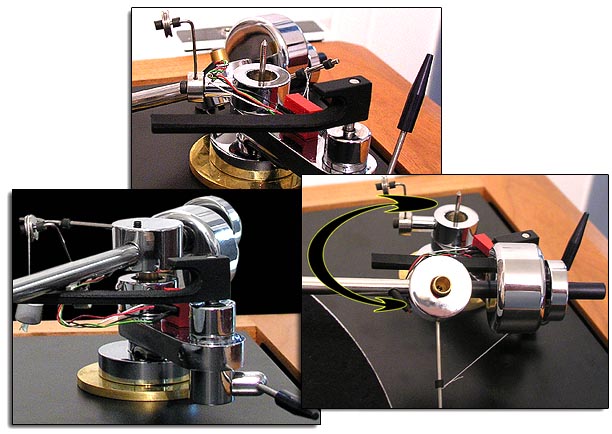

The 228 was a great piece of quaint British hifi at a reasonable price. I had hours of fun tweaking and fettling mine and it sounded great.

Back in the day if you rang the number for customer service you would get Mr George Hadcock himself.

Very helpful he was too.

Back in the day if you rang the number for customer service you would get Mr George Hadcock himself.

Very helpful he was too.