awl

pfm Member

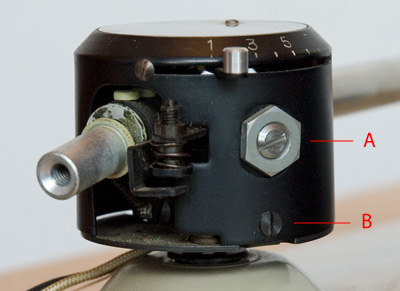

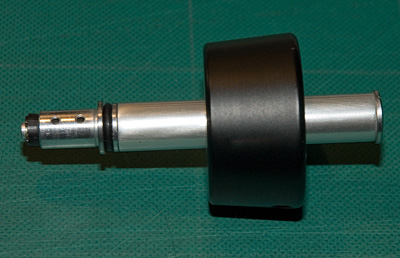

I am trying to renovate a BTD 12S Tonearm on a recently acquired Thorens TD135. The condition of the turntable is very good - I suspect it hasn't seen use for many years and so there are a number of issues with moving parts, including the arm. The counterweight stub is held in place with a now perished rubber coupling, and the counterweight now sags at an alarming angle to the rest of the arm. So the first thing I need to do is replace this coupling. To do so I need to undo two screws on the end of the arm, but these aren't easily accessed without dismantling more of the cylinder that covers the bearings and other bits. Here are some pictures:

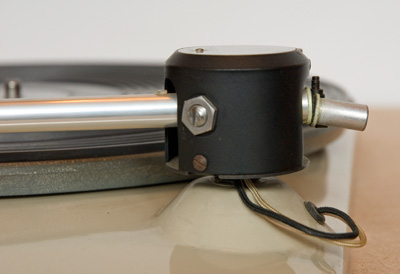

I've removed the aluminium top plate and this gives a bit more access to the inside workings, but still not enough to get a screwdriver on the two screw heads:

I've downloaded some drawings of the arm from Vinyl Engine and other sites, but none seem to show how to access these two screws. Can anyone with experience of this arm or others like it suggest what I could try? Which screws to undo and just as importantly which ones I should leave alone!

I suspect that the bearings on the tonearm could also do with some fresh lubricant and any advice on how to go about this (and with what) would also be greatly appreciated.

Andrew

I've removed the aluminium top plate and this gives a bit more access to the inside workings, but still not enough to get a screwdriver on the two screw heads:

I've downloaded some drawings of the arm from Vinyl Engine and other sites, but none seem to show how to access these two screws. Can anyone with experience of this arm or others like it suggest what I could try? Which screws to undo and just as importantly which ones I should leave alone!

I suspect that the bearings on the tonearm could also do with some fresh lubricant and any advice on how to go about this (and with what) would also be greatly appreciated.

Andrew