Mike Reed

pfm Member

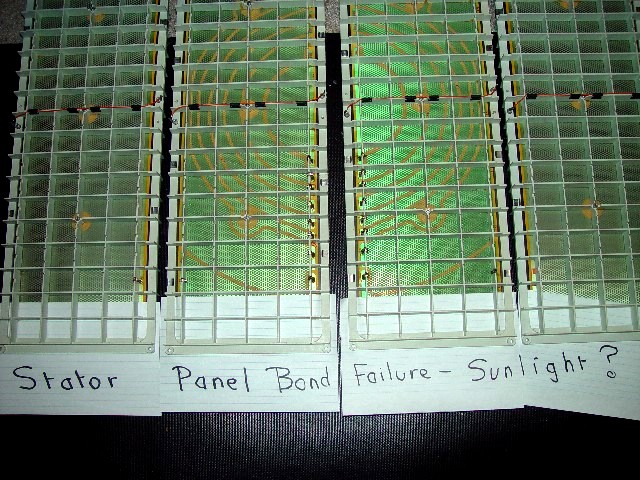

Since converting to big ESLs (QUAD 2905) I've often wondered how one tells if anything is amiss. With coil speakers, it's easy to simply listen to each speaker unit, but cloth-covered ESLs are not so obvious.

How would one tell, e.g., if one panel is down? Simply by listening close up to six (in my case) different parts of the front cover? This is not definite as it depends upon the music, surely.

I know nothing about if/how a panel can expire or, really, anything about modern ESLs, nor how many bass as opposed to treble panels there are (4 x bass, 2 x treble?). Could a bang from a blown fuse take out all or individual panels, despite supposedly having excellent safety precautions built in?

ESL learning curve starting, hopefully.

How would one tell, e.g., if one panel is down? Simply by listening close up to six (in my case) different parts of the front cover? This is not definite as it depends upon the music, surely.

I know nothing about if/how a panel can expire or, really, anything about modern ESLs, nor how many bass as opposed to treble panels there are (4 x bass, 2 x treble?). Could a bang from a blown fuse take out all or individual panels, despite supposedly having excellent safety precautions built in?

ESL learning curve starting, hopefully.